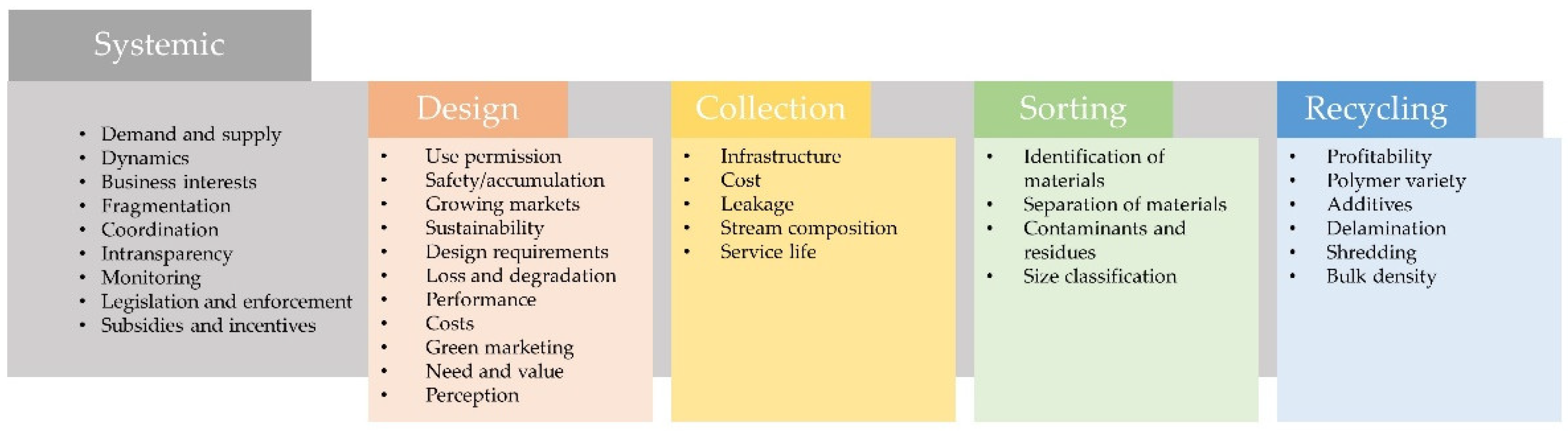

What Are the Key Obstacles Faced When Recycling Metalized Food Packaging?

Metalized food packaging is a type of packaging that includes a thin layer of metal, usually aluminum, laminated onto plastic or paper. This metal layer helps block light, oxygen, and moisture. It keeps food fresh longer without many preservatives and protects from damage. Because it preserves quality and extends shelf life, manufacturers use it widely in snacks, coffee bags, and vacuum-sealed pouches.

Common Types of Metalized Food Packaging

The most common metalized packaging types include:

- Snack bags (potato chips, popcorn)

- Coffee bags with foil lining

- Vacuum-sealed pouches for meat or seafood

- Candy wrappers and confectionery packaging

These flexible packages are lightweight and cost-effective. However, while they are great at protecting food, they introduce significant complications in recycling.

How Metal Layers Affect Recyclability Compared to Conventional Plastics

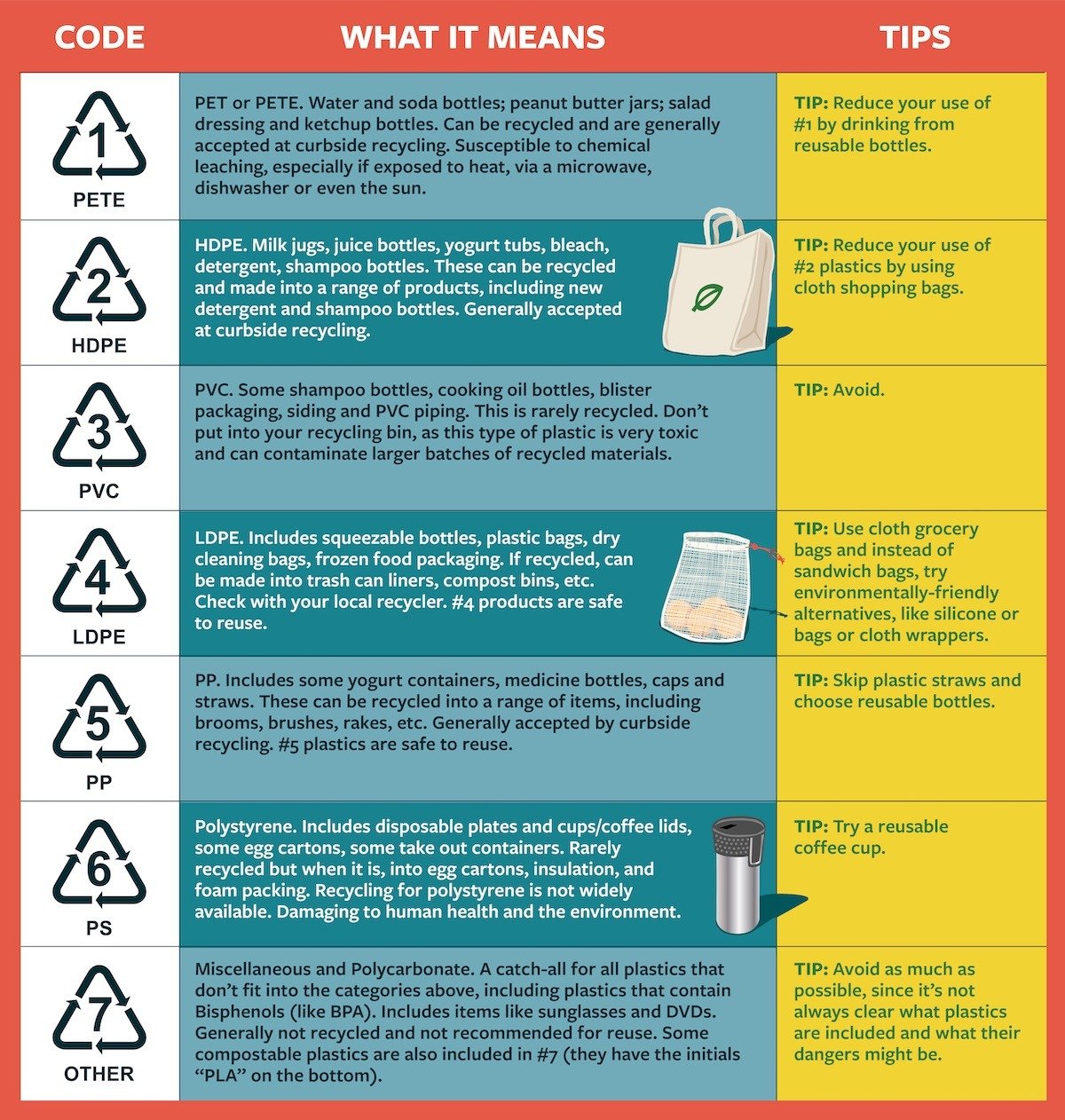

The metal layer creates a barrier that is excellent for food preservation but tough on recyclers. Unlike pure plastic packaging, metalized layers cannot be easily melted or processed alongside plastics. This means metalized packaging cannot be recycled through standard plastic recycling streams. The metal disrupts the melting process, reducing recyclate quality. It also contaminates batches of recyclables, making sorting and purification harder.

Physical Properties That Complicate Recycling Processes

Metalized food packaging is often a multi-layer composite. These packages contain layers of:

- Plastic films such as PET (polyethylene terephthalate), PE (polyethylene), or nylon

- A thin metal foil, usually aluminum

- Adhesive layers bonding metal and plastic

- Printing inks and coatings

This sandwich of different materials makes separation nearly impossible with current technologies. Because each layer has different melting points and chemical properties, recycling facilities cannot process them together. Mechanical recycling is nearly unusable here. Thermal methods cannot melt one layer without damaging others. Chemical recycling remains costly and rare.

| Layer | Common Material | Recycling Challenge |

|---|---|---|

| Outer layer | PET or Nylon | High melting point, requires sorting |

| Metal layer | Aluminum foil | Incompatible with plastics |

| Adhesive layers | Various adhesives | Hard to separate chemically |

| Ink coatings | Pigments and dyes | Contaminate recycling streams |

Impact of Food Residue Contamination

Food residue stuck on metalized packaging creates a big problem. Because these packages hold oily or sticky foods, residue often remains inside. This contaminates the recycling stream, lowering product quality and increasing cost. Recycling plants may reject loads contaminated with food waste to protect machinery and final material quality.

Residue contamination means recyclers must pre-wash materials. Washing requires water and energy, raising operational costs and reducing recycling efficiency. Unfortunately, many consumers do not rinse packaging thoroughly before disposal, worsening contamination rates.

Difficulty in Separating Metalized Layers

Separating the metal foil from plastic or paper layers is technically challenging. The metal film is bonded tightly with adhesives to plastic films. Mechanical peeling is ineffective, and current chemical separation methods are costly and environmentally unfriendly.

This inability to separate layers means metalized packaging is often classified as “non-recyclable” in many municipal programs. The mixed material then ends up in landfills or incinerators, defeating sustainability goals.

Challenges from High Ink and Adhesive Content

Metalized food packaging often carries heavy ink coverage for branding and product info. These inks include pigments and solvents that further pollute recyclates and complicate de-inking processes. Adhesives used to bond layers add another layer of contamination, reducing the purity of recycled plastics.

High ink and adhesive contents demand advanced chemical treatments or labor-intensive processes to remove, which few recycling facilities have.

Lack of Consumer Awareness and Education

A major barrier to recycling metalized packaging comes from consumers. Many people do not know if metalized wrappers are recyclable, and often throw them in the wrong bin. When metalized packaging mixes with regular recyclables, it contaminates entire batches, damaging machinery and increasing processing costs.

According to recent studies, up to 30% of contamination in recycling streams stems from improper disposal of complex plastic packaging like metalized films. Education around what can and cannot be recycled needs improvement. Without clear messaging, consumers hesitate, causing valuable materials to be lost.

Safety Risks Faced by Recycling Workers

Recycling workers handling metalized food packaging face certain risks. The tiny aluminum particles from shredded metalized films can cause respiratory irritation or injury. Combined with inks and adhesives, these materials produce harmful dust or fumes during processing.

Additionally, metal fragments can damage machinery or cause injuries. This leads to increased safety protocols but also deters workers from joining or staying in the recycling workforce, creating labor shortages.

Inadequate Recycling Infrastructure and Support

Many recycling centers cannot process metalized food packaging due to a lack of suitable technology or financial incentive. Unlike PET or HDPE bottles, metalized flexible packaging lacks standardized recycling methods.

Some cities do not provide special collection bins for flexible or metalized packaging. Where available, these programs often require extra costs and are not widely promoted. Rural areas lack accessible recycling facilities, further reducing recovery rates.

Summary of Key Obstacles for Metalized Food Packaging Recycling

| Obstacle | Explanation |

|---|---|

| Multi-layer composites | Hard to separate metal & plastics |

| Food residue contamination | Requires costly pre-washing |

| Inks and adhesives | Pollute recyclate, resist removal |

| Consumer confusion | Incorrect disposal increases contamination |

| Worker safety risks | Dust, metal shards, chemicals |

| Lack of infrastructure | Few facilities equipped for complex packaging |

| Market demand | Low value for recycled metalized materials |

Metalized food packaging remains a recycling challenge worldwide. It protects food but blocks easy recovery of materials. Overcoming these barriers demands innovations in packaging design, consumer education, and recycling technology. Until then, many metalized packages continue bypassing recycling, fueling waste and landfill burden.

How Do Economic and Technological Limitations Affect Recycling of Metalized Food Packaging?

Recycling metalized food packaging faces many hurdles. These obstacles arise from both economic factors and technological limits. Let me walk you through these challenges and why they make recycling metalized food packaging tough.

Economic Barriers Metalized Packaging Recycling Faces

One major economic challenge involves the high cost of separating metalized food packaging components. These packages are usually multi-layered, combining plastic, metal films, and sometimes paper. Separating these layers takes more labor, energy, and specialized equipment than recycling simple plastics or metals.

This separation cost is often greater than the value of the recovered materials. The market demand for recyclates from metalized packaging remains low because these recycled materials lack pure quality and consistency. Companies that buy recycled feedstock usually prefer virgin plastics because they are cheaper and more reliable, especially when oil prices are low.

Speaking of oil prices, they fluctuate a lot, and this greatly influences markets for recycled materials. When virgin plastic becomes cheap due to lowered oil prices, recycled metalized plastics lose their price appeal. For example, during the COVID-19 pandemic, oil prices dropped below $20 a barrel, causing a slump in demand for recycled content. On the other hand, recent supply chain disruptions have increased raw material costs, causing recycled feedstock to rise in value again. Still, this volatility makes investments in recycling metalized packaging risky.

| Economic Factors Impacting Metalized Packaging Recycling | Description |

|---|---|

| High Separation Costs | Multi-layer packaging requires complex processes and equipment. |

| Low Market Demand | Recycled materials are lower quality and less in demand. |

| Virgin Plastic Price Fluctuations | Cheap virgin plastics reduce recycled material demand. |

| Lack of Incentives | Limited government subsidies or mandates for metalized packaging recycling. |

Technological Challenges Recycling Metalized Packaging Faces

Sorting and processing metalized packaging pose serious technological challenges. The metal layers (often aluminum) are ultra-thin and bonded with multiple plastic films. This structure creates a multi-layer polymer composite that is very hard to recycle at scale.

Current sorting machines, like near-infrared (NIR) spectroscopy and AI-powered systems, struggle to identify and separate these materials accurately. NIR works well with common plastics but faces limitations with shiny metal films since metals reflect and absorb different wavelengths. This causes sorting errors, with metalized plastics mixed into other recycling streams, dropping recyclate quality.

Additionally, high ink and adhesive content on metalized wrappers further complicates processing. The ink layers often use complex chemistries that resist traditional de-inking and cleaning. Adhesives bonding layers together hinder efficient material separation, raising processing times and energy use. Food residue also contaminates packaging, causing recycling facilities to reject or downgrade materials.

Why is this so hard? Multi-layer polymers combine materials with different melting points like PET and PE polymers plus the metal layer. This difference prevents melting and reforming as a single material without destroying one layer. Thus, recycling facilities find it challenging to recycle these composites cleanly and efficiently.

Sorting Technologies and Their Limitations

Many recycling centers use AI-powered optical sorting, combined with NIR spectroscopy, to speed sorting throughput. These technologies are advancing but still not perfect for metalized packaging. For example:

- NIR can detect common plastics: PET, HDPE, PP, etc., very accurately.

- Metalized films from metal layers confuse the sensors due to reflection and thinness.

- AI systems rely on visual and spectral data but cannot always distinguish thin metal layers or multi-material blends.

This technology gap causes many metalized packages to end up in landfill or waste-to-energy lines rather than being recycled properly.

Innovation Emerging to Improve Recycling Technology

On the bright side, new technologies aim to address these problems:

| Innovation | Description |

|---|---|

| Hyperspectral imaging | Captures more light spectrum data to improve metal detection. |

| Solvent-based recycling | Dissolves plastic layers to separate materials effectively. |

| Mono-material metalized films | Simplify recycling by reducing multi-layer complexity. |

| AI improvements | Machine learning increases sorting accuracy for composites. |

Still, these technologies are expensive, need scale-up, and require significant investment.

Regional Differences Affect Recycling Infrastructure

Recycling infrastructure varies widely by region, affecting metalized food packaging recycling rates:

- Some regions, especially in Europe, have better recycling laws and facilities equipped with advanced technologies. Higher recycling rates for all plastics, including flexible and metalized packaging, are observed.

- In many parts of the U.S. and developing countries, infrastructure does not support flexible or metalized materials recycling. Often, there is no separate collection for flexible packaging or advanced sorting equipment.

- Regulations also differ. Some states have mandates that push companies to recycle or reduce packaging waste, while others lack such policies.

This patchwork leads to uneven sustainability progress. Recycling metalized food packaging requires infrastructure upgrades, regional coordination, and clear policy direction.

Government Role and Investment

Government investment and policy can play a key role in overcoming economic and technological barriers:

- Governments can offer grants and subsidies to recycling facilities to acquire advanced sorting and processing equipment.

- Introducing extended producer responsibility (EPR) laws can hold manufacturers accountable for the end-of-life management of metalized packaging.

- Educational campaigns funded by governments increase consumer awareness, reducing contamination in recycling streams and boosting material quality.

States like New York have food scraps recycling mandates linked to packaging waste, setting a precedent for integrated policy.

Contamination Impact on Recycling Efficiency and Costs

Food residue, ink, and adhesives contaminate metalized packaging, raising costs and reducing recycling efficiency.

- Contamination requires additional cleaning steps, increasing water and energy use.

- Residues cause machinery blockages or damage, leading to downtime and repair costs.

- Contaminated recyclates fetch lower prices due to poor quality.

- Consumer misunderstanding leads to improper recycling—liquids and food waste mix with recyclables, disrupting operations.

For example, in 2019, less than 5% of U.S. food waste was composted partly because of contamination in organic waste streams. Contaminants from packaging make recycling metalized materials even more difficult.

Summary Table of Challenges

| Challenge Area | Description |

|---|---|

| Economic Barriers | High separation cost, low recyclate demand, volatile costs |

| Technological Challenges | Multi-layer composites, sorting errors, contamination |

| Infrastructure Gaps | Regional differences, lack of flexible packaging recycling |

| Policy and Investment | Need for subsidies, regulations, and producer responsibility |

| Contamination Effects | Residues and inks raise costs, reduce material quality |

Understanding these economic and technological limitations helps reveal why recycling metalized food packaging is so complex. Overcoming these hurdles requires innovation, better infrastructure, policy support, and consumer education.

What Solutions and Innovations Can Improve the Recycling of Metalized Food Packaging?

Recycling metalized food packaging faces many obstacles. However, there are promising solutions and innovations to improve the process. Let’s explore how these advances can make a difference.

Design Strategies to Improve Recyclability

One effective approach is changing how packaging is designed. Mono-material packaging uses a single type of plastic instead of multiple layers. This makes sorting and recycling simpler because there’s no need to separate different materials like plastic and metalized films.

Using bio-based inks is another solution. Traditional inks contain heavy metals and chemicals that contaminate recycling streams. Bio-based inks are made from natural materials and break down easily during recycling without causing damage or pollution.

These design changes help keep recycling streams cleaner and reduce the costs involved in processing metalized containers.

Consumer Education to Reduce Contamination

Consumer knowledge needs a boost to reduce recycling contamination. Many people don’t realize that food residue or non-recyclable items in bins can ruin entire batches of recyclables. For metalized food packaging, leftover food often clings to the plastic-metal layers, creating major problems.

Educational campaigns that teach:

- How to rinse and clean packaging before recycling,

- What types of metalized packaging are recyclable,

- Where to find recycling centers that accept complex materials,

can improve recycling quality across communities.

Clear, simple labels on packaging to guide consumers also help prevent mistakes and contamination.

Smart Packaging Technologies for Better Recycling

Technology can make recycling metalized food packaging more efficient. Using QR codes or digital tracking on packages lets consumers and recyclers scan items to learn if and how the package can be recycled.

These smart labels can also:

- Register recycling attempts for data analysis,

- Alert companies about defective packaging,

- Guide sorting machines at recycling plants.

With accurate information, recycling infrastructures can optimize processes, reduce contamination, and boost overall recycling rates.

Collaboration to Build Better Recycling Systems

No one group can improve recycling alone. When industries, governments, and recyclers work together, the chances for success grow. For example, manufacturers can design recyclable packages while governments provide incentives and pass laws that require recycling.

Recyclers share feedback on which packaging types are easy or hard to process. Joint efforts can fund infrastructure upgrades like modern sorting facilities and curbside collection programs.

Public-private partnerships offering grants or tax breaks encourage companies to innovate and align with sustainability goals.

Bio-Based and Biodegradable Packaging Alternatives

Some companies explore bio-based or biodegradable packaging as alternatives to metalized films. These materials come from renewable sources like plants and break down naturally in compost or soil.

Examples include:

| Material Type | Source | End-of-Life Option | Key Challenge |

|---|---|---|---|

| Polylactic Acid (PLA) | Corn, sugarcane | Industrial composting | Requires special facility |

| Cellulose Films | Wood pulp | Compostable or recyclable | Moisture sensitivity |

| Starch-based films | Potatoes, corn | Biodegradable | Durability limitations |

While bio-based films promise lower environmental impact, challenges with cost and functional performance remain. Testing and scaling these materials help improve their usability.

Legislative and Extended Producer Responsibility (EPR) Programs

Legislation plays a vital role. Laws like New York’s Food Donation and Food Scraps Recycling Law (effective 2022) mandate recycling or donating food scraps over a threshold. Similar policies encourage or require packaging producers to take responsibility for recycling.

EPR programs make brands pay for collection and recycling costs. This pushes companies to design more recyclable metalized packaging and support recycling infrastructure financially.

Such programs incentivize innovation and help develop circular value chains.

Case Studies of Successful Recycling Innovations

Here are some real examples:

- TerraCycle’s Loop Program: Provides reusable packaging systems that replace single-use metalized wrappers, reducing waste.

- Mondi Group’s Mono-Material Films: Developed recyclable mono-material metalized films used for snacks and coffee bags.

- AMP Robotics: Uses AI and robotics to sort metalized packaging more accurately in recycling plants.

These successes show how innovation can improve recycling yields and reduce landfill disposal.

On-site Food Scrap Dehydration and Depackaging

These technologies reduce contamination problems by separating food waste from packaging directly at waste collection sites or retail locations.

- Dehydration units shrink food scraps by removing moisture, lowering weight and volume for transport.

- Depackaging machines extract clean food waste from wrappers so food can be composted or anaerobically digested separately.

This approach keeps metalized packaging cleaner, making recycling easier and more efficient.

Future Trends Toward Circular Economy Models

Looking ahead, circular economy models aim to keep metalized food packaging materials in use longer.

Promising trends include:

- Designing fully recyclable or reusable packaging,

- Embedding smart sensors to track freshness and recycling data,

- Enhancing bio-based material blends for better durability and recyclability,

- Expanding local recycling infrastructure with automated sorting technology,

- Widespread adoption of EPR schemes and recycling mandates.

Together, these innovations can turn metalized food packaging from a recycling hassle into a resource.

Recycling metalized food packaging has many challenges, but solutions exist. Through better design, education, technology, collaboration, and new materials, the recycling rates can rise. These efforts align with global goals to reduce food waste, limit plastic pollution, and build a sustainable future.

FAQs about Obstacles and Solutions in Recycling Metalized Food Packaging

What are the key obstacles faced when recycling metalized food packaging?

The key obstacles faced when recycling metalized food packaging include multi-layer composites that are difficult to separate, contamination from food residue, inks, and adhesives, consumer confusion causing improper disposal, safety risks to recycling workers due to metal particles and chemicals, and inadequate recycling infrastructure and market demand.

How do economic and technological limitations affect recycling of metalized food packaging?

Economic and technological limitations affect recycling of metalized food packaging by creating high separation costs that often exceed material value, low market demand for recycled products, challenges in sorting due to multi-layer structures and metal interference with sensors, and lack of adequate recycling infrastructure in many regions.

Why is separating metalized layers from plastic in food packaging so difficult?

Separating metalized layers from plastic in food packaging is difficult because these layers are bonded tightly with adhesives and have different melting points and chemical properties, making mechanical peeling ineffective and chemical separation costly and environmentally challenging.

What solutions and innovations can improve the recycling of metalized food packaging?

Solutions and innovations to improve recycling of metalized food packaging include designing mono-material packaging to simplify recycling, using bio-based inks to reduce contamination, educating consumers about proper cleaning and disposal, deploying smart packaging technologies like QR codes for better sorting, and investing in advanced recycling technologies and infrastructure.

How does consumer behavior impact the recycling of metalized food packaging?

Consumer behavior

Metalized food packaging poses many recycling challenges. Its multi-layer makeup and metal films make sorting and processing tough. Food residue and inks add more hurdles, while current technology and infrastructure struggle to keep up. Economic and market issues also limit recycling efforts. Still, better design, smarter tech, and stronger laws can help improve recycling rates. Educating consumers to reduce contamination is key. We must push innovation and partnerships to solve these problems and keep metalized packaging from filling landfills. Recycling this material is hard, but smart solutions make it possible.