What Are Metalized Food Packaging Materials and Why Are They Difficult to Recycle?

When we talk about metalized food packaging, we refer to packaging materials that have a thin layer of metal, usually aluminum, coated or laminated onto plastic films or paper. This metal layer adds a shiny or reflective surface, often seen in snack bags, coffee pouches, and frozen food wraps. Metalized packaging is popular because it keeps food fresh by blocking out light, oxygen, and moisture. This helps extend shelf life and prevents contamination, which is vital in the food industry.

Types of Metalized Food Packaging

Metalized packaging comes in various forms, including:

- Metalized Films: Thin plastic films coated with a very thin layer of aluminum, usually less than a micron thick. These are flexible and used for snacks, candy wrappers, and coffee bags.

- Metal Foils: Thicker sheets of pure aluminum, often used for wrapping chocolate or baking food.

- Laminates: Multiple layers of different materials (such as plastic, paper, and aluminum foil) combined for durability and barrier properties.

- Multilayer Structures: Complex combinations like PET-Aluminum-PE (Polyethylene) layers fused together. These offer the best protection but are the hardest to separate for recycling.

Each type has unique benefits for preserving food but poses specific challenges when it comes to recycling.

Why Is Metalization Used in Food Packaging?

Metalization provides crucial barrier properties. It blocks light that can cause spoilage. It also stops oxygen and moisture from reaching the food. This keeps food fresh longer and reduces food waste. For example, a snack bag made with metalized film can keep chips crisp weeks longer than plain plastic.

Beyond freshness, metalization adds strength and prevents contamination during transport and storage. However, these benefits come with a major drawback: recycling difficulty.

How Metalized Packaging Differs From Conventional Packaging in Recycling

Standard plastic or paper packaging is easier to recycle. For plastics, items are often made from a single polymer type—like polyethylene (PE) or polyethylene terephthalate (PET). Paper packaging breaks down well in standard recycling processes.

Metalized packaging, by contrast, is a fusion of materials. The metal layer is bonded tightly to plastic films or paper. This mix of metal, plastic, and sometimes paper makes it hard for recycling machines to separate each component. Typical recycling systems are optimized for single-material streams, not complex laminates.

Common Compositions That Complicate Recycling

The most common metalized food packaging materials are multi-layer structures such as PET-Aluminum-PE. These layers look like this:

| Layer | Material | Purpose |

|---|---|---|

| Outer | PET (plastic) | Durability, printing surface |

| Middle | Aluminum foil | Barrier to light, oxygen |

| Inner | PE (plastic) | Heat seal, food contact |

Because these layers are fused, recycling requires separating each material. Current recycling tech struggles with this. The aluminum can't be removed cleanly, and the plastic layers mix with metal residues, lowering the quality of recycled output.

Impact of Adhesives, Inks, and Printing Technologies

Metalized packaging often includes adhesives to bond layers and inks for branding. These substances add further recycling problems:

- Adhesives stick materials tightly, making mechanical separation tough.

- Inks and dyes can bleed or leave residues that contaminate recycling batches.

- Specialized printing techniques (such as metallic inks or varnishes) introduce elements that may not be recyclable or may interfere with sorting machines.

Current Recycling Infrastructure for Metalized Packaging

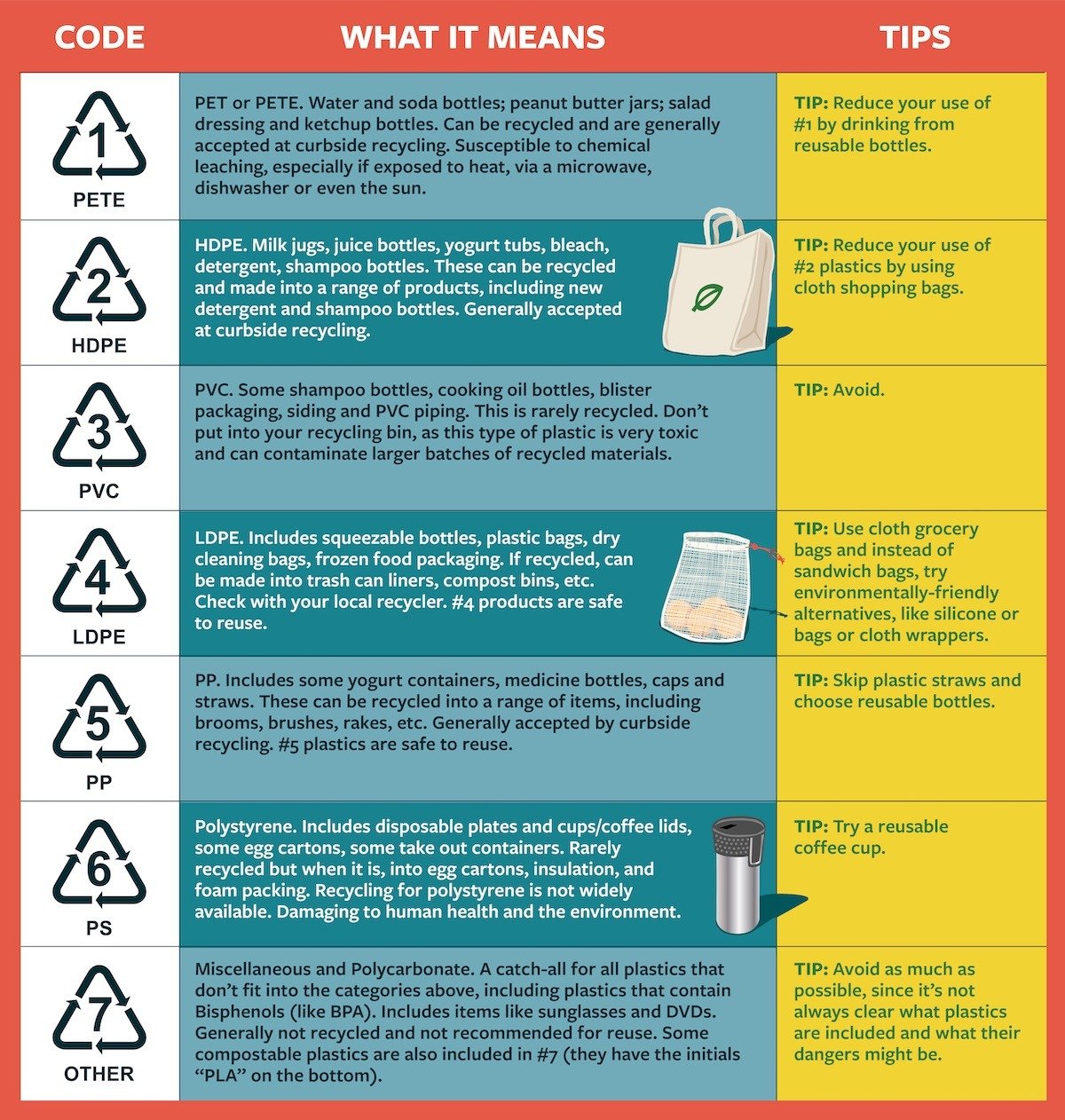

Most municipal recycling systems are not equipped to recycle metalized food packaging well. Common recycling streams accept plastics labeled #1 through #7 but expect them to be clean and single-material.

The sorting facilities use Near-Infrared (NIR) sensors or manual sorting, but these systems cannot detect or separate ultra-thin metal layers. Thus, metalized packaging often gets sorted incorrectly.

Recycling plants generally do one of three things with metalized packaging:

- Reject it as contamination: Leading to extra costs and landfill disposal.

- Send it to mixed plastic recycling: This reduces the quality and value of recycled plastic.

- Burn it for energy recovery: But this wastes materials and produces emissions.

What Happens When Metalized Packages Enter Regular Recycling Streams?

When metalized packages enter regular recycling, they cause several issues:

- They can contaminate batches of plastic recyclables, reducing recyclate quality.

- The metal layers are not extracted, so the final recycled product may have tiny metal fragments.

- Sorting machines can get clogged or damaged by sticky adhesives or mixed materials.

- Workers may have to manually remove troublesome packaging, raising labor costs and safety concerns.

These problems lead many recycling facilities to reject metalized packaging entirely or send the material to landfill or incineration.

Summary Table: Metalized Food Packaging vs. Conventional Packaging in Recycling

| Criterion | Conventional Plastic/Paper | Metalized Food Packaging |

|---|---|---|

| Material Composition | Single polymer or pure paper | Multilayer plastics and metals |

| Recyclability | High if clean | Low due to bonded layers |

| Sorting Process | Easily detected by NIR | Difficult due to thin metal layer |

| Contamination Risk | Lower | Higher (inks, adhesives, residues) |

| Treatment in Recycling | Recycled into new products | Often rejected or downcycled |

| Economic Value of Output | Higher | Lower due to contamination |

What Are the Key Obstacles Faced When Recycling Metalized Food Packaging?

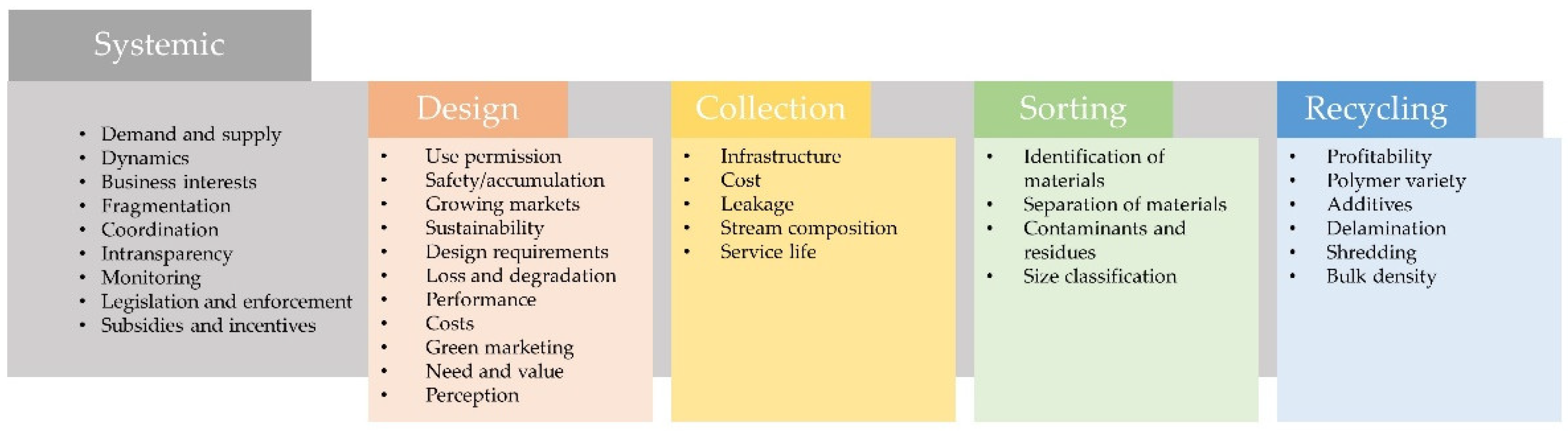

Recycling metalized food packaging is a tough job, and there are many obstacles that make it hard for this material to be reused. If you want to understand the real challenges, you need to look at several key areas, such as technical issues, contamination, sorting difficulties, economic factors, and consumer behavior. Let me share the main obstacles I've identified when recycling metalized food packaging.

Technical Challenges: Separation of Metal Layers from Plastics and Other Materials

Metalized food packaging often contains thin layers of metals like aluminum combined with plastics such as PET or polyethylene. Separating these metal layers from plastic is very difficult. The layers bond tightly together, making simple mechanical or chemical separation a big technical challenge.

Because of this, most recycling plants cannot process these multi-layer packs as they usually require clean, single-material streams. The metalized layer can cause a batch of plastic recycling to be contaminated, reducing the value of the recycled product or causing the entire batch to be rejected.

Contamination Problems: Food Residues, Inks, Adhesives, and Their Effects on Recycling Quality

Food packaging often has leftover food inside. This food residue can spoil the recycling process. For example, greasy crumbs or sticky sauces stick to the packaging and make it harder to clean and recycle.

Inks and adhesives used for printing labels and sealing the packaging add another layer of contamination. Many inks are made with pigments that do not come off easily during recycling, while adhesives can gum up machinery or lower the quality of recycled plastic.

Contamination is one of the main reasons recycled materials from metalized packaging have low market value or get diverted to landfill after collection.

Sorting Difficulties: Multi-Material Packaging and Advanced Technologies

Sorting metalized packaging is tough due to its mixed-material nature. Modern recycling centers use optical sorting and AI-based systems like Near-Infrared (NIR) spectroscopy to separate plastics by type. However, metal layers below the plastic films confuse these sensors because they reflect light differently.

This causes misidentification or misclassification, leading metalized packages into the wrong recycling stream. When mixed with other plastics, they can spoil the batch or damage sorting equipment.

Lack of Standardized Recycling Protocols or Labeling

Currently, there are no universal recycling rules or labels specifically designed for metalized food packaging. Consumers often get confused about whether they can recycle these items or not.

Without clear instructions at the product level and standardized processing protocols, most metalized packaging ends up in the trash or landfill, missing the recycling opportunity.

Limited Specialized Recycling Facilities

Special recycling plants exist that can handle multilayer metalized packaging, but they are scarce. These facilities use advanced technologies like solvent-based delamination or pyrolysis to break down and reclaim materials separately.

Unfortunately, the cost is high, and the number of such facilities is limited globally. This lack of infrastructure reduces the overall recycling rate of metalized food packaging.

Economic Barriers: Cost Versus Value of Recycled Material

Metalized packaging is costly to recycle because of these technical and sorting challenges. The expense of removing metal layers, cleaning contaminants, and managing complex processes sometimes outweighs the market value of the recycled output.

Virgin plastics, especially with low oil prices in recent years, can be cheaper than recycled plastics. This economic imbalance discourages investments in metalized packaging recycling.

Safety and Operational Hazards for Recycling Workers

Recycling metalized packaging also brings safety issues for workers. The metal layers can contain sharp edges, risking cuts. Chemical residues from inks and adhesives may pose health risks. Machinery handling mixed materials can jam or break, causing accidents.

These hazards reduce the appeal for workers to stay in the recycling industry, challenging labor availability.

Consumer Behavior Issues: Confusion and Improper Disposal

Many consumers are unsure if metalized packaging is recyclable. This confusion leads to wrong disposal behavior, such as tossing metalized packs in regular trash or dirty recycling bins.

Improper separation increases contamination in recycling streams, causing large batches of recyclables to be sent to landfill. Public education is critical to improving recycling quality, yet it remains a major challenge worldwide.

Case Studies: Recycling Rejection and Landfill Dumping Due to Metalized Food Packaging

A study in India showed that over 70% of flexible consumer packaging is metalized multilayer films. Because of contamination and sorting issues, the recycling rate remains below 5%. Most of this material ends up in landfills or energy recovery plants.

In the U.S., municipal recycling facilities often reject loads if metalized food packaging contamination exceeds 5%. This rejection contributes to millions of tons of packaging waste being landfilled yearly, despite consumer efforts.

| Obstacle | Impact on Recycling Quality and Rate |

|--------------------------------|-----------------------------------------------------------|

| Metal-plastic separation | High rejection rates, reduced recyclate purity |

| Food residues and adhesives | Contamination, machinery damage, lower output quality |

| Sorting complexity | Misclassification, increased operational costs |

| Lack of protocols and labeling | Consumer confusion, waste misdirection |

| Limited specialized facilities | Low capacity to process metalized packaging properly |

| Cost vs. recycled material value| Economic non-viability limits investments |

| Worker safety risks | Reduced workforce participation and operational setbacks |

| Consumer disposal behavior | Contamination and increased landfill waste |

What Are Emerging Solutions and Future Directions to Improve Recycling of Metalized Food Packaging?

Recycling metalized food packaging faces many challenges, but the future looks promising. Thanks to new solutions and innovations, we can expect better recycling rates and less waste. Let me walk you through key advances and trends shaping the landscape for metalized packaging recycling.

Advances in Mono-Material Metalized Packaging

A major breakthrough involves creating metalized packaging made from mono-materials rather than multiple layers. Traditional metalized films combine plastics like PET with aluminum layers and adhesives, making them hard to separate and recycle.

Mono-material metalized films replace these complex blends with one type of plastic coated to offer metal-like barrier properties. This approach keeps advantages such as protecting food from oxygen and moisture but simplifies recycling.

Some brands now use fully PET-based metalized films that recyclers can process easily in existing systems. This reduces the need for specialized treatment and lowers contamination risk.

Benefits of mono-material packaging include:

- Easier sorting and processing

- Improved recyclate quality

- Reduced production and recycling costs

A 2023 study showed mono-material films improved recycling yield by up to 35% compared to conventional multilayer ones.

Development of Bio-Based and Biodegradable Alternatives

Another exciting solution is bio-based and biodegradable packaging with metal-like barrier features. These materials often come from plants, such as cellulose or polylactic acid (PLA), and break down faster in nature.

Researchers have developed coatings and films mimicking metal's barrier functions, protecting food just as well. If widely adopted, these materials could reduce plastic waste and reliance on fossil fuels.

Some pilot projects use bio-based films coated with thin layers of bio-plastic or natural minerals to achieve shelf life comparable to metalized films. Though costs remain higher, scaling production could push prices down.

Biodegradable materials also ease recycling, either by composting or by supporting traditional recycling streams without harmful residues.

Improvements in Sorting Technology: AI, Near-Infrared Spectroscopy, and Robotics

Sorting recycled materials is key to recycling metalized packaging efficiently. Metalized films often confuse machines because they combine plastic with metal-like layers, making identification tough.

New sorting tech uses Artificial Intelligence (AI) combined with Near-Infrared (NIR) spectroscopy to identify materials with much higher accuracy and speed. AI analyzes the material's spectral signature and guides robots to separate different types automatically.

Key benefits include:

- Reduced contamination rates

- Faster sorting lines

- Ability to detect thin metal coatings and multilayer films

Robotics enable less human handling, improving safety and lowering labor costs. Many recycling facilities are testing or already adopting AI-powered sorting systems to improve the quality of recycled output from metalized packaging.

Industry Collaboration to Standardize Packaging Design for Recyclability

No single company can solve metalized packaging recycling alone. Cross-industry collaboration plays a huge role in developing standards for recyclable packaging design.

Several packaging manufacturers, food producers, and recycling organizations now work together to:

- Agree on a list of materials and designs that recyclers can handle

- Avoid complex laminates and adhesives that hinder processing

- Harmonize labeling for recyclability to reduce consumer confusion

This cooperation helps create a clearer, unified market that supports investment in recycling infrastructure and innovation.

Government Policies Supporting a Circular Economy for Food Packaging

Government policies push improvements in packaging and recycling. Many countries are crafting rules and incentives to foster a circular economy—where materials are reused and recycled continuously rather than thrown away.

For example:

- Regulations require food producers to use more recyclable packaging

- Extended Producer Responsibility (EPR) laws make companies financially responsible for recycling

- Funding programs support infrastructure development and recycling research

New York’s 2022 law mandates waste diversion by large food waste generators, including recycling efforts that involve packaging.

Government action is vital to boost the supply chain’s recycling capacity and encourage businesses to innovate towards sustainable packaging.

Consumer Education and Labeling to Reduce Contamination and Improve Recycling Rates

Education is often overlooked but essential. Contamination from food residues, mixed materials, and improper disposal causes many recyclable metalized packages to go to landfills.

Clear, simple labels telling consumers how to recycle metalized food packaging correctly help reduce errors. Signs such as "Recycle if clean and empty" or icons showing correct bins can guide behavior.

Similarly, public campaigns increase awareness about the challenges metalized packaging poses and how proper disposal can help.

Studies show that well-designed labels can increase recycling participation by 20% or more.

Successful Recycling Models and Pilot Projects Focused on Metalized Packaging

Several pilot projects demonstrate how metalized packaging recycling can work at scale:

| Project Name | Location | Approach | Results |

|---|---|---|---|

| RecycleFlex Pilot | Europe (Netherlands) | Mono-material films & AI sorting | Increased recyclable yield by 30% |

| BioBarrier Challenge | USA | Bio-based packaging development | Shelf life comparable to metalized films |

| Circular Pack Forum | Global | Industry standardization initiative | Standard designs adopted by 15 brands |

These examples show practical steps toward overcoming obstacles and helping recyclers and producers align.

Economic Incentives and Investments in Recycling Infrastructure

Money drives change. Recycling facilities need funding to upgrade equipment like AI sorters or to handle novel bio-based materials. Economic incentives such as tax breaks or grants encourage companies to invest in research and infrastructure.

The value for recycled materials from metalized packaging remains low, so subsidies or guaranteed purchase agreements can make recycling financially viable.

Increased investment also supports training workers for safe handling of complicated materials and reduces industrial risk.

Digital Innovations: QR Codes for Traceability and Consumer Guidance

Digital tools like QR codes printed directly on metalized packaging help with traceability and consumer engagement.

Scanning a code can tell consumers how to recycle that specific package or inform recyclers about its material composition. Producers can use data gathered to improve designs or monitor recycling performance.

This technology enhances transparency, connects stakeholders, and can boost recycling rates by offering clear, personalized guidance.

Additional Table: Summary of Challenges and Emerging Solutions

| Challenge | Emerging Solution | Expected Outcome |

|---|---|---|

| Difficult material separation | Mono-material metalized films | Easier recycling, higher yield |

| Contamination by inks and food | Improved sorting AI and robotics | Reduced contamination and damage |

| Lack of standardized labeling | Industry collaboration and consumer education | Better recycling participation |

| Limited recycling infrastructure | Government funding and economic incentives | Expanded processing capacity |

| Consumer confusion | Clear recycling instructions and QR code usage | Improved disposal behavior |

What Happens When Improper Disposal Affects the Recycling Stream?

Misplaced or dirty metalized packaging harms recycling streams, leading to contamination and increased landfill waste. Public awareness and infrastructure improvements are essential to tackle these negative impacts.

By focusing on these emerging solutions and future directions, we can slowly but surely address the obstacles faced when recycling metalized food packaging. Industry, government, technology, and consumers all play a part in making packaging more sustainable and recyclable.

FAQs about Identify obstacles faced when recycling metalized food packaging:

What are the main technical challenges in recycling metalized food packaging?

The main technical challenges in recycling metalized food packaging involve the difficult separation of metal layers from plastic films or paper, as these materials are tightly bonded to create multilayer structures that recycling plants cannot easily process.

How do contamination issues affect recycling quality of metalized food packaging?

Contamination issues affect recycling quality by introducing food residues, inks, and adhesives that can spoil the recycling process, gum up machinery, and reduce the purity and market value of the recycled materials.

Why is sorting metalized food packaging difficult in recycling facilities?

Sorting metalized food packaging is difficult because the thin metal layers alter the way optical and Near-Infrared (NIR) sensors identify materials, leading to misclassification and contamination of recycling streams.

What economic barriers limit the recycling of metalized food packaging?

Economic barriers limit recycling because the costs associated with separating materials, cleaning contaminants, and managing complex processes often exceed the market value of the recycled output, making recycling financially unattractive.

How does consumer behavior contribute to challenges in recycling metalized food packaging?

Consumer behavior contributes to challenges as confusion about recyclability leads to improper disposal and contamination in recycling bins, causing more metalized packaging to be rejected or sent to landfills.

Metalized food packaging uses layers of metal and plastic to keep food fresh but poses big recycling problems. Its complex layers, inks, and adhesives make sorting and processing hard. Contamination and limited recycling facilities add to the challenge. However, new tech and industry efforts aim to improve recyclability. Better designs, smarter sorting, and clearer labels can help. We all play a role—by learning and recycling right, we support a cleaner future. The key is innovation paired with cooperation across the entire supply chain.