What Are the Key Industry Standards for Metalized Film Production?

When it comes to Detail industry standards for metalized film production, it helps to know the key organizations that write and enforce these standards. The major players here are ASTM International, ISO, and BIS in India. These bodies set the rules for materials, coatings, barrier qualities, and testing to ensure metalized films meet performance and safety needs.

Major Industry Standards Organizations Relevant to Metalized Films

- ASTM International: A leading standards developer headquartered in the US. ASTM creates test methods, material specifications, and product standards widely used worldwide.

- International Organization for Standardization (ISO): This global body develops standards for materials and quality systems. ISO standards are recognized internationally and ensure consistent quality.

- Bureau of Indian Standards (BIS): In India, BIS develops and enforces standards specific to Indian industries, including packaging materials and metalized film production.

Each organization plays a critical role. ASTM and ISO gather inputs from industry experts and researchers, while BIS focuses on Indian market needs and regulatory compliance.

Specific ASTM and ISO Standards Governing Metalized Film Materials and Barrier Properties

There are vital standards that metalized film producers must adhere to, especially regarding materials and barrier features like oxygen and moisture blocking.

| Standard Body | Standard Number | Purpose |

|---|---|---|

| ASTM | ASTM D5729 | Defines the terminology, materials, and test methods for metalized polymer films |

| ASTM | ASTM F1249 | Method to test water vapor transmission rate (WVTR) in films |

| ASTM | ASTM D3985 | Oxygen permeability measurement for packaging films |

| ISO | ISO 25178-2 | Surface texture characterization, related to film quality and coating uniformity |

| ISO | ISO 15686 | Testing barrier properties of films, including oxygen and moisture transmission |

| BIS | IS/ISO 22000 | General quality management system for food packaging materials, relevant for metalized films |

| BIS | IS 17027 | Indian standards for packaging materials and test methods |

These standards help ensure that metalized films maintain barrier qualities to extend shelf life, prevent moisture ingress, and preserve product freshness.

Regulatory Guidelines Affecting Metalized Film Production

In India, given the packaging industry's growth (projected CAGR ~27%), strict packaging laws apply for consumer safety. Metalized films used in food must follow:

- FSSAI (Food Safety and Standards Authority of India) guidelines, which require materials to be safe for food contact.

- The Plastic Waste Management Rules (2016) mandate recyclable and eco-friendly packaging materials.

- BIS certifications ensure films meet Indian product safety and quality benchmarks.

- International regulations like FDA compliance (for exports) and EU packaging directives affect metalized film production aimed at global markets.

Compliance is crucial to avoid import/export hurdles and meet consumer safety laws.

Definitions and Terminologies in Metalized Film Production Standards

Understanding common terms used in metalized film standards is key:

| Term | Definition |

|---|---|

| Metalized Film | A polymer film coated with a thin metal layer, usually aluminum, for barrier and visual effects |

| Barrier Properties | The ability of a film to block gases (oxygen), moisture, or aromas |

| WVTR (Water Vapor Transmission Rate) | Measures moisture passing through film in grams/m²/day |

| OTR (Oxygen Transmission Rate) | Amount of oxygen passing through a film over time |

| Physical Vapor Deposition (PVD) | Vacuum process used to coat films with metal layers |

| Optical Density | The film’s ability to absorb or block light, related to opacity and reflectiveness |

These terms often appear in standard documents and certificates.

Role of Standard-Setting Bodies in Updating and Enforcing Quality Benchmarks

Organizations like ASTM, ISO, and BIS regularly revise standards to:

- Incorporate technology advances (e.g., new coatings or substrates)

- Address environmental and safety concerns (such as recyclability or biodegradability)

- Harmonize global specifications for easier trade

- Introduce new test methods for better quality assessment

They also collaborate with industry players to enforce compliance through certifications and audits, ensuring products meet uniform quality benchmarks.

Differences Between Standards for Food Packaging and Industrial Applications

Metalized films for food packaging require stricter standards due to direct food contact. These standards emphasize:

- Food safety and material migration limits

- Strong barrier properties (low WVTR and OTR)

- Heat sealability for airtight packaging

- Printed ink safety for consumer products

Industrial films, like those used in electronics or insulation, focus more on:

- Mechanical strength and durability

- Thermal resistance

- Electrical insulation properties

- Less strict barrier or safety requirements compared to food films

This distinction ensures films match their end use without excessive cost or over-engineering.

Certification and Quality Compliance Requirements

To sell metalized films commercially, manufacturers must obtain certifications proving compliance:

- BIS certification for Indian markets

- ISO 9001 Quality Management System certification

- Food contact compliance certificates (FSSAI or FDA)

- Testing reports for barrier, mechanical, and optical properties according to ASTM/ISO standards

- Factory audits and inspections ensure consistent production quality

These certificates reassure buyers and regulators about product safety and reliability.

How Emerging Sustainability Regulations Influence Metalized Film Standards

New rules worldwide push for greener packaging. Metalized films must adapt to:

- Enhance recyclability or biodegradability (e.g., oxo-biodegradable films)

- Reduce energy consumption in production (improved PVD efficiency)

- Limit use of toxic substances in coatings and inks

- Increase use of recycled materials

These factors are gradually integrated into standards. Standard bodies update requirements to include:

- Life cycle assessments

- Sustainable material guidelines

- Recyclability labeling and testing

Such changes help metalized films stay competitive in a market demanding eco-friendly choices.

Understanding these Detail industry standards for metalized film production gives a solid base if you’re working in the field or looking to source metalized films. Following the right standards ensures quality, safety, and market access.

How Are Metalized Films Produced According to Industry Standards?

Metalized film production follows strict industry standards to achieve top quality, durability, and performance. The process involves several key steps: preparing the base polymer film, treating its surface, applying metal via Physical Vapor Deposition (PVD), and adding protective coatings. Let’s explore each stage in detail, focusing on how manufacturers maintain uniformity and meet strict quality criteria.

Physical Vapor Deposition (PVD) Process

The core of metalized film manufacturing is the Physical Vapor Deposition (PVD) technique. In this process, metals such as aluminum, chromium, or nickel are vaporized inside a high-vacuum chamber. The evaporated metal atoms travel through the vacuum and deposit uniformly onto the cold surface of polymer films. This allows an ultra-thin metal layer, generally between 20 to 100 nanometers, to coat the film with a shiny, metallic finish.

Industry standards require precise control of vacuum conditions—pressures typically range from 10^-5 to 10^-6 torr—to avoid contamination and ensure even deposition. Temperature control within the vacuum chamber is also critical; too high or too low temperatures can affect metal adhesion and film integrity.

Preparation of Base Polymer Films

Before metallization, base films like polyethylene terephthalate (PET), polypropylene (PP), and nylon are carefully selected and prepared. These polymers must meet strict specifications:

| Polymer Type | Key Properties | Common Applications |

|---|---|---|

| PET | High tensile strength (>170 MPa), thermal stability (Tg ~80°C), good clarity | Food packaging, electronics |

| PP | Low density (0.90-0.91 g/cm³), moisture and fat resistance, cost-effective | Snack wraps, bakery packaging |

| Nylon | Excellent puncture resistance, chemical stability | High barrier packaging, technical uses |

Manufacturers ensure films are free from defects, contaminants, and must align with thickness ranges, typically 6 to 250 microns, depending on intended application.

Surface Treatment for Metal Adhesion

Polymer films naturally have low surface energy, making metal adhesion difficult. To address this, industry standards mandate surface treatments before metallization. The two most common methods are corona and plasma treatments.

- Corona Treatment: Employs high-voltage electrical discharge to raise surface energy above 38 dynes/cm, roughening the film surface microscopically.

- Plasma Treatment: Uses low-pressure ionized gases to clean and activate the film surface.

Both methods improve bonding sites so metal particles adhere uniformly, reducing the risk of poor coating or flaking. Strict control over treatment intensity and duration ensures repeatable results.

Vacuum Chamber Controls for Uniform Coating

The vacuum chamber environment is a crucial factor for standard-compliant metal coating. Pressure and temperature are monitored continuously. Films move on rollers inside the chamber to allow even exposure to metal vapor.

Key parameters include:

- Vacuum Level: Maintained at 10^-5 to 10^-6 torr to reduce impurities.

- Substrate Temperature: Typically kept low (near ambient or slightly elevated) to avoid film deformation.

- Deposition Rate: Optimized for consistent metal atom flux, usually controlled in angstroms per second.

These controls help achieve metal layers without uneven thickness or clustering, critical for optical and barrier properties.

Measuring Metal Layer Thickness and Uniformity

Industry standards require precise measurement of the metal layer’s thickness and uniformity, critical for product performance. Typical thickness ranges span from 20 nm to 100 nm.

Measurement techniques include:

- Quartz Crystal Microbalance (QCM): Inline monitoring tool measuring deposition rate and total thickness during production.

- Spectrophotometry: Non-destructive optical method assessing reflectivity and film optical density.

- Electron Microscopy: Used in lab settings for detailed thickness and surface morphology analysis.

Uniform coating prevents weak spots, which might reduce barrier effectiveness or cause pinholes.

Techniques to Enhance Durability and Prevent Pinholes

Pinholes are micro-defects that lower barrier performance and durability. Industry standards stipulate several techniques to minimize these defects:

- Optimized drying and cooling of films before metallization to avoid surface irregularities.

- Controlled deposition environment to reduce contaminants.

- Multi-layer coatings combining metal layer with protective polymers.

- Tension management on films during coating to prevent micro-tears.

These approaches maintain high barrier integrity, supporting oxygen and moisture resistance critical for food and pharma packaging.

Post-Metallization Protective Coatings

After metal deposition, films typically receive a protective layer to increase abrasion resistance and prevent oxidation. These coatings are usually transparent polymer layers such as:

- Polyurethane

- Acrylic varnishes

Protective coatings aid compliance with industry standards by preserving the metal’s reflective properties and extending shelf life. They also enhance machinability and print compatibility.

Quality Assurance Checkpoints During Production

Throughout metalized film manufacturing, multiple quality assurance tests ensure compliance with standards and customer specifications. Common checkpoints include:

- Pre-treatment Film Inspection: Checks thickness, surface cleanliness.

- Surface Energy Measurement: Ensures adequate corona/plasma effect.

- Vacuum and Deposition Monitoring: Controls chamber environment and metal thickness.

- Post-Metallization Inspection: Detects pinholes, measures adhesion strength.

- Optical Quality Tests: Assesses gloss and reflectivity.

- Barrier Testing: Validates oxygen and moisture transmission rates.

These tests are documented rigorously to support certifications and traceability.

Summary Table of Key Metalized Film Production Parameters

| Production Stage | Industry Standard Requirements |

|---|---|

| Base Film | PET/PP/nylon with defined thickness & tensile specs |

| Surface Treatment | Corona/plasma; surface energy > 38 dynes/cm |

| Vacuum Environment | Pressure: 10^-5 to 10^-6 torr; temperature control |

| Metal Layer Thickness | 20-100 nanometers uniform |

| Protective Coating | Transparent polymer layers for abrasion and oxidation resistance |

| Quality Control Points | Film inspection, adhesion tests, optical & barrier tests |

What Are the Critical Quality Parameters and Testing Methods for Metalized Films?

When working with metalized films, understanding their quality standards and testing methods is key. These films combine polymer layers with thin metal coatings, offering unique benefits like good barrier properties, visual appeal, and lightweight strength. Let’s explore the critical quality criteria and how they are tested to meet industry standards.

Essential Physical Properties and Their Tests

Metalized films must have strong physical properties to survive packaging, transport, and storage. These include several key measurements:

- Tensile Strength: Measures how much pull force the film can handle before breaking. Typical tests use standardized setups like ASTM D882. Values over 170 MPa for PET films are standard.

- Elongation at Break: Tells how much the film stretches before snapping. It reflects flexibility and toughness.

- Tear Resistance: Assesses the film’s ability to resist propagating tears, crucial for handling and machine use.

- Puncture Resistance: Indicates protection against sharp object penetrations.

- Abrasion Resistance: Tests how resistant the film is to surface wear from rubbing.

- Fold Resistance: Measures the film’s ability to withstand repeated folding without cracking.

Standard test methods such as ASTM D1922 (tear resistance) and ASTM D5748 (puncture resistance) guide these evaluations. Results ensure the film holds up during manufacture and use, minimizing pack damage and waste.

Barrier Performance Criteria

Metalized films primarily act as moisture and oxygen barriers. This feature extends shelf life and preserves food quality. The key barrier measures are:

- Oxygen Transmission Rate (OTR): The rate at which oxygen passes through the film. Lower OTR means better oxygen barrier. Metalized films reduce oxygen transmission by 98-99.5% compared to base polymers.

- Water Vapor Transmission Rate (WVTR): Shows moisture permeability. A low WVTR keeps products dry.

- Grease Resistance: Important for snacks and bakery items, tested with methods like TAPPI T 559.

- Aroma Barrier: Prevents flavor losses and keeps aromas fresh. It’s tested by gas chromatography or sensory panels.

These parameters are vital for foods and pharmaceuticals that require controlled atmospheres. Industry benchmarks often set OTR below 5 cc/m²/day and WVTR below 1 g/m²/day for high-barrier films.

Optical Properties Assessment and Packaging Impact

Metalized films add a shiny, metallic look that boosts shelf presence. Standards guide optical metrics to ensure consistent quality and consumer appeal:

- Reflectivity: Measures how much light is reflected, typically 40–90% specular reflectance for metalized PET.

- Gloss: Indicates surface shine; higher gloss improves visual appeal.

- Haze: Lower haze means clearer film.

- Optical Density: Relates to color darkness and opacity. Values around 1.8 to 3.0 produce the bright silver effect.

According to ASTM D1003 (haze) and ASTM D523 (gloss), films must meet set targets to maintain branding image and acceptance. Studies show metallic sheen can increase consumer attention by up to 37%.

Heat Sealability and Temperature Resistance

Packaging often requires strong seals to keep contents safe. Metalized film quality standards include:

- Heat Sealability: Assessed by ASTM F88, this tests seal strength under set heat and pressure. Good seal strength prevents leaks.

- Temperature Resistance: Films are exposed to temperature cycles matching storage or processing conditions, including freezer or oven tests. PET films resist up to about 80°C, while some PP films perform better in heat sealability.

Ensuring compatibility with packaging machines like horizontal and vertical form-fill-seal (HFFS, VFFS) lines is critical for production efficiency.

Chemical Resistance and Printability

Films also face chemical exposures and require excellent surface traits for printing:

- Chemical Resistance: Evaluated by exposing films to common substances (acids, solvents) to check for degradation or loss of barrier.

- Printability: Surface energy tests confirm ink adhesion is reliable across different printing methods such as flexography, offset, UV, and letterpress.

Good printability means branding and regulatory info are clear and durable, enhancing product trust.

Standardized Test Procedures and Instruments

Quality measurement follows standard procedures to ensure reproducibility and comparability:

| Property | Test Method | Key Instrument |

|---|---|---|

| Tensile Strength | ASTM D882 | Universal Testing Machine |

| Elongation at Break | ASTM D882 | Universal Testing Machine |

| Tear Resistance | ASTM D1922 | Elmendorf Tear Tester |

| Puncture Resistance | ASTM D5748 | Puncture Tester |

| Oxygen Transmission Rate | ASTM D3985 | Mocon OX-TRAN Analyzer |

| Water Vapor Transmission Rate | ASTM F1249 | Mocon Permatran Analyzer |

| Gloss | ASTM D523 | Gloss Meter |

| Haze | ASTM D1003 | Haze Meter |

| Heat Seal Strength | ASTM F88 | Heat Seal Tester |

Using modern instruments and calibrated setups assures metalized films meet strict quality norms.

Table: Typical Quality Benchmarks for Metalized Films

| Parameter | Typical Specification Range | Purpose/Impact |

|---|---|---|

| Tensile Strength (PET) | >170 MPa | Durability during packaging and handling |

| Oxygen Transmission Rate | <5 cc/m²/day | Shelf life extension via oxygen barrier |

| Water Vapor Transmission Rate | <1 g/m²/day | Moisture barrier for product protection |

| Reflectivity | 40% – 90% specular reflectance | Visual appeal and brand impact |

| Heat Seal Strength | >1.5 N/mm | Secure packaging seals |

| Optical Density | 1.8 – 3.0 | Metallic brightness and opacity |

Documentation and Quality Certification

For certification and regulatory compliance, metalized film producers maintain detailed records including:

- Raw material certifications

- Test reports and compliance certificates

- Process parameters and metal layer thickness logs

- Non-conformance and corrective action reports

Such documentation supports national and international standards like BIS (Bureau of Indian Standards), ASTM, and ISO. It also facilitates audits and customer trust in product quality.

The blend of physical, barrier, optical, and processing property tests forms a robust quality framework. This ensures metalized films deliver performance, aesthetics, and safety that the growing packaging sector in India and worldwide demands.

Summary Table for Industry Standards and Testing

| Aspect | Related Standards & Tests | Key Points |

|---|---|---|

| Materials & Definitions | ASTM D5729, ISO 25178-2 | Standard terminology, surface texture |

| Barrier Properties | ASTM D3985 (OTR), ASTM F1249 (WVTR) | Essential barrier metrics |

| Physical Tests | ASTM D882 (tensile), ASTM D1922 (tear), ASTM D5748 (puncture) | Strength and durability measurement |

| Optical Properties | ASTM D523 (gloss), ASTM D1003 (haze) | Appearance and consumer appeal |

| Production Controls | Vacuum pressure & temperature ranges, corona/plasma treatment | Uniform coatings and adhesion |

| Certification & Compliance | BIS, ISO 9001, FSSAI/FDA certificates | Market and regulatory acceptance |

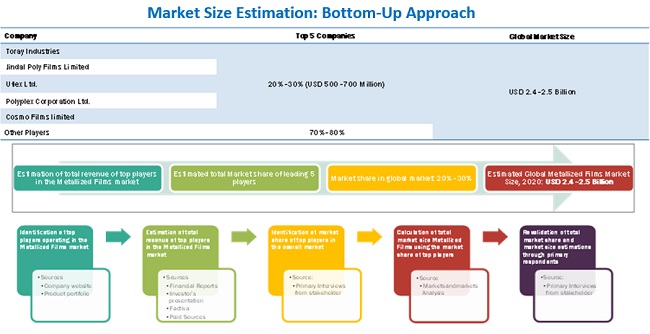

Additional Image on Market and Trends

FAQs about Detail industry standards for metalized film production

What are the key organizations that set industry standards for metalized film production?

The key organizations that set industry standards for metalized film production include ASTM International, ISO, and the Bureau of Indian Standards (BIS). These bodies develop specifications for materials, coatings, barrier qualities, and testing methods to ensure quality and safety.

How is the quality of metalized films measured in terms of barrier properties?

The quality of metalized films in terms of barrier properties is measured using Oxygen Transmission Rate (OTR) and Water Vapor Transmission Rate (WVTR), with OTR measuring oxygen permeability and WVTR measuring moisture passage, both critical to extending product shelf life.

What steps are involved in metalized film production according to industry standards?

Metalized film production involves preparing the base polymer film, applying surface treatments like corona or plasma to improve metal adhesion, performing Physical Vapor Deposition (PVD) under controlled vacuum and temperature conditions, and applying protective coatings to enhance durability.

How do manufacturers ensure uniform metal layer thickness and prevent defects like pinholes?

Manufacturers ensure uniform metal layer thickness by controlling vacuum pressure (typically 10^-5 to 10^-6 torr), temperature, and deposition rate during PVD, and they prevent pinholes through optimized drying, multi-layer coatings, and tension management during film handling.

What quality assurance tests are conducted to verify compliance with metalized film standards?

Quality assurance tests include

In this article, I covered the main standards and processes that shape metalized film production. We looked at key bodies like ASTM and ISO, the physical steps in making films, and how quality tests ensure strong, reliable films. These standards guide manufacturers to meet both local and global rules. Remember, staying updated on these rules is essential as new demands for recycling and safety grow. Knowing these industry standards helps you trust the films used in packaging and industry. It’s clear that quality and compliance must go hand in hand.