What Are Metallized Polypropylene Films and What Are Their Key Properties?

Metallized polypropylene films are a type of plastic film coated with a thin layer of metal, usually aluminum or zinc. These films start as polypropylene (PP), a lightweight, flexible, and chemically resistant plastic. The metal layer is added through a process called vacuum metallization, creating a very thin metallic coating on the film's surface. This coating gives the film significantly improved barrier, electrical, and mechanical properties compared to plain polypropylene.

What Is Metallized Polypropylene Film? Definition and Basic Composition

At its core, metallized polypropylene film consists of two parts:

- A polypropylene base film—this is a biaxially-oriented plastic sheet, meaning it has been stretched in two directions to improve strength and clarity.

- A metal coating—usually aluminum or sometimes zinc applied in a thin, even layer.

This composite material combines the benefits of plastic film—like flexibility, transparency, and resistance to chemicals—with the protective and conductive qualities of metal. The metal coating, often only a few nanometers thick, turns polypropylene into a highly functional film for many industrial uses.

How Is Metallized Polypropylene Film Produced? Overview of Metallization Process

The production involves a vacuum chamber setup where the metal source (aluminum or zinc) is heated until it vaporizes. The polypropylene film is passed through this vacuum environment, allowing the metal vapor to condense and coat one or both sides of the film evenly.

The key steps are:

- Film extrusion and orientation: The polypropylene film is first extruded and biaxially oriented to increase strength.

- Cleaning: To ensure good metal adhesion, the film surface is cleaned and sometimes pre-treated.

- Metallization: Aluminum or zinc is vaporized in a vacuum chamber, and the metal vapor deposits as a thin film on the polypropylene.

- Winding and finishing: The metallized film is cooled and rolled for further use.

This process creates a film with a uniform reflective metal layer that adheres strongly to the plastic without affecting flexibility much.

What Are the Physical and Chemical Properties of Metallized Polypropylene Films?

Metallized polypropylene films have excellent physical and chemical traits, which include:

- Durability: They resist tearing and puncturing better than many other plastic films.

- Barrier properties: The metal layer gives superior protection against oxygen, moisture, light, and odors. This extends product shelf life in packaging.

- Flexibility: The films remain supple and easy to shape, unlike some rigid metal foils.

- Chemical resistance: Polypropylene is naturally resistant to acids, bases, and solvents, making it ideal for diverse environments.

- Thermal resistance: These films can maintain performance across wide temperature ranges, often between -40 °C to +120 °C.

- Electrical properties: The film acts as a dielectric, especially important in capacitor uses, resisting electrical conductivity except through its metal layer.

How Do Metallized Coatings (Aluminum, Zinc) Enhance Polypropylene Film Functionality?

Aluminum is the most common metal coating. It provides:

- High reflectivity for light and heat, useful in insulation and decorative applications.

- Excellent barrier performance, reducing gas and vapor permeability drastically.

- Electrical conductivity, enabling their use in electronic components like capacitors.

Zinc coating is less common but used where enhanced corrosion resistance is needed and for specific electronic functions.

This thin metal layer makes the film suitable for packaging sensitive food and medical products, reflective insulation, and electrical components needing reliability and stability.

What Are Common Types and Thickness Ranges of Metallized Polypropylene Films?

The polypropylene base film thickness typically ranges from 6 to 50 microns (μm). The metal coating is ultra-thin, at 5-50 nanometers (nm), invisible to the naked eye but highly functional.

Common types include:

- Single-sided metallized films: Metal coated on one side only.

- Double-sided metallized films: Metal on both sides for increased barrier and conductivity.

- Specialty films: Treated for anti-static, printable surfaces, or enhanced mechanical strength.

Choosing the right thickness and metal layer depends on the end-use, whether packaging, electrical insulation, or decorative film.

| Film Type | Metal Coating | Typical Base Film Thickness | Applications |

|---|---|---|---|

| Single-sided metallized | One side (Al or Zn) | 6 to 50 µm | Flexible packaging, decorative uses |

| Double-sided metallized | Both sides | 6 to 50 µm | Electrical insulation, capacitors |

| Specialty metallized films | Treated surfaces | Varies | Anti-static, printable, durable |

What Makes Metallized Polypropylene Film Different from Other Plastic Films like PET, PVC, PE?

Compared to PET (polyester) films:

- Metallized PP offers better flexibility and chemical resistance.

- PET has higher mechanical strength and thermal stability but is less flexible.

Compared to PVC:

- PP is more chemically stable and less brittle at low temperatures.

- Metalized PP provides better barrier properties and lighter weight.

Compared to PE (polyethylene):

- PP films are stiffer but clearer and more resistant to heat.

- PE tends to be softer and used where flexibility is key.

The combination of metallization and PP’s natural properties creates a film that balances strength, flexibility, barrier protection, and cost effectively.

How Do Metallized Polypropylene Films Perform Under Various Environmental Conditions?

- Temperature: They function well in cold and hot environments, maintaining barrier and mechanical properties.

- Moisture: The metal coating blocks moisture vapor transmission, protecting packaged goods and electronics.

- UV Exposure: Without UV stabilizers, metallized PP films degrade under UV light, but formulations exist with additives for outdoor use.

- Mechanical stress: They resist flexing and cracking better than some rigid plastic or metal films.

This versatility means metallized polypropylene films can work indoors or outdoors, in packaging, electronics, and beyond.

What Are the Self-Healing and Dielectric Properties Relevant to Capacitor Applications?

One unique and vital property is self-healing. If a tiny breakdown occurs in the metal layer inside a film capacitor, the metal surrounding the fault vaporizes, isolating the flaw and restoring function. This allows capacitors to continue operating without catastrophic failure.

The dielectric property relates to polypropylene's strong electrical insulation capability. It has:

- Low dielectric loss, meaning energy loss during charge/discharge cycles is minimal.

- High breakdown voltage, allowing operation under high voltages.

- Stable capacitance across temperature ranges.

Together, these properties make metallized polypropylene films favored dielectric materials in high-performance capacitors used in power electronics, audio devices, and renewable energy systems.

Summary Table: Metallized Polypropylene Film Characteristics

| Property | Description | Benefit |

|---|---|---|

| Base Material | Biaxially oriented polypropylene | Flexibility, chemical resistance |

| Metal Coating | Aluminum or zinc (5-50 nm) | Barrier protection, conductivity |

| Film Thickness | 6 to 50 microns | Strength, application-specific flexibility |

| Barrier Properties | Moisture, oxygen, light | Shelf life extension, product protection |

| Electrical Properties | High dielectric strength, self-healing | Capacitor reliability and longevity |

| Environmental Resistance | Temperature, moisture, UV (with stabilizers) | Versatility in multiple applications |

| Mechanical Strength | Tear, puncture resistance | Durability in packaging and handling |

This deep dive into metallized polypropylene films highlights their complex production and their unique physical, chemical, and electrical properties. These make them indispensable in industries ranging from food packaging to advanced electronics, where high performance and reliability matter.

In Which Industries and Applications Are Metallized Polypropylene Films Used?

Metallized polypropylene films find many uses in various industries due to their unique properties. As you examine various applications for metallized polypropylene films, it’s clear these films play a vital role in packaging, electronics, insulation, labeling, and more. Let me walk you through the main application areas, highlighting how these films boost product quality and performance.

Applications in Packaging: Barrier, Safety, and Looks

In packaging, metallized polypropylene films serve as excellent barrier layers. They protect products from moisture, oxygen, and light which can spoil food or reduce shelf life. The thin metal layer, usually aluminum, reflects light and blocks gases effectively.

- Food safety and preservation: These films help keep snacks, frozen foods, and fresh produce fresher for longer by limiting exposure to air and contaminants.

- Aesthetic appeal: Their glossy, reflective surface gives packages a premium look that attracts consumers. Metallization enhances printability and color vibrance on flexible packaging.

- Durability: The films resist tearing and punctures, protecting fragile or delicate food items during transport.

For example, snack companies often use metallized films to keep chips fresh while making the bag eye-catching. The balance of barrier protection and shine makes metallized polypropylene irreplaceable in flexible food packaging.

Metallized Polypropylene Films in Capacitor Manufacturing and Electronics

One of the critical industrial applications of metallized polypropylene films lies in capacitor manufacturing. These films are ideal dielectrics in film capacitors, wound with metal coatings to form compact, reliable components.

Here’s why they matter in electronics:

- High capacitance and efficiency: The polypropylene dielectric allows capacitors to store more charge with low energy loss, critical for power supplies, audio devices, and lighting circuits.

- Self-healing property: When small defects appear, these capacitors automatically isolate the fault, extending lifespan and avoiding failure.

- Withstand high voltage: Metallized polypropylene capacitors perform well in high-voltage applications like automotive electronics and renewable energy systems.

- Long life and stability: Their stable electrical properties make them top choices for precision electronics and critical circuits.

In power electronics, these capacitors improve efficiency and noise reduction. Audio equipment benefits from cleaner sound, and motor control uses the capacitors for interference reduction.

Use in Insulation and Electrical Component Protection

Metallized polypropylene films provide electrical insulation and protect components from damage and environmental effects.

- They act as insulating layers in transformers, motors, and sensors.

- Their chemical stability and heat tolerance guard against moisture, dust, and temperature swings.

- The films prevent short circuits and insulation breakdowns, enhancing overall reliability in electrical devices.

This application is especially vital in industrial and automotive sectors, where electrical components face harsh conditions.

Benefits in Labeling and Decorative Finishes

Beyond protection, metallized polypropylene films bring value in labels and decorative finishing.

- Their metallic sheen makes labels look upscale and attractive.

- The films hold ink well, enabling sharp, vibrant printing.

- Their durability helps label longevity on products exposed to moisture or abrasion.

- Flexible and conformable, they wrap around containers of various shapes without cracking.

Brands use these films to ensure their labels stand out on grocery shelves or consumer goods.

Contribution to Renewable Energy and Automotive Electronics

Metallized polypropylene films support cutting-edge fields like renewable energy and automotive electronics.

- In solar inverters and wind turbine power converters, metallized polypropylene capacitors aid in energy storage and smooth power flow.

- Automotive applications include electric vehicle control units, battery management, and noise filtering within audio systems.

- Their durability and ability to handle temperature extremes meet the rigorous demands of these high-tech systems.

This makes metallized polypropylene a key material in the green energy and electric mobility revolution.

Applications in Medical Packaging and Sterile Environments

The films also play a role in medical packaging.

- Their barrier properties help maintain sterile conditions, preventing bacterial contamination.

- Flexible and lightweight, they seal medical devices or pharmaceuticals hygienically.

- Classified as safe and inert, they meet strict medical standards for health safety.

Hospitals and pharmaceutical companies use metallized polypropylene film packaging to ensure product sterility and freshness.

Key Considerations in Selecting Metallized Polypropylene Films

When choosing these films for any application, consider:

| Factor | Why It Matters | Example |

|---|---|---|

| Durability | Resist tears, punctures, and flexing | Packaging snacks that undergo transport |

| Printability | Accepts inks for labels and decorations | Product branding and instructions |

| Temperature Resistance | Remain stable under heat during use or processing | Capacitors in automotive electronics |

| Surface Shape | Flat or curved substrates require flexibility | Labeling curved bottles |

| Barrier Requirements | Level of moisture, oxygen barrier needed | Food packaging versus medical packaging |

Balancing these factors ensures the films fit their industrial application perfectly.

Case Studies Highlighting Metallized Polypropylene Film Uses

- Snack Packaging Company: Switched to metallized polypropylene film liners. Result: Extended shelf life by 30%, reduced packaging weight, and enhanced package appeal.

- Renewable Energy Manufacturer: Implemented metallized polypropylene film capacitors in solar inverters. Result: 25% boost in power efficiency and improved device longevity.

- Medical Device Supplier: Used metallized polypropylene film pouches for sterile packaging. Result: Zero contamination incidents and easier regulatory compliance.

These examples underscore the versatility and value metallized polypropylene films bring across sectors.

Which Industries Benefit Most from Metallized Polypropylene Films?

Key beneficiaries include:

- Food and beverage packaging

- Electronics and electrical manufacturing

- Automotive industry

- Renewable energy systems

- Medical and pharmaceutical sectors

- Consumer goods labeling and decorations

Their barrier protection, durability, and electrical properties improve product performance and reliability.

How Do Metallized Polypropylene Films Improve Product Performance in Packaging and Electronics?

- Enhance shelf life and food safety by blocking moisture and gases.

- Make packaging more attractive with shiny, printable surfaces.

- Boost capacitor efficiency through high dielectric strength and self-healing.

- Provide insulation and protection in sensitive electronic components.

- Support high-voltage, harsh-environment applications with temperature stability.

In short, metallized polypropylene films deliver a powerful mix of protection, functionality, and visual appeal. This drives innovation and quality across many industries.

How Do Metallized Polypropylene Films Enhance Capacitor Performance and What Are Maintenance Best Practices?

Metallized polypropylene film capacitors are a key component in many electronic circuits. These capacitors use thin layers of polypropylene film coated with a metal, usually aluminum or zinc. The metal is vapor-deposited on both sides of the film, and then the film is rolled into a cylindrical shape. This design allows capacitors to be strong, efficient, and compact.

The film acts as the dielectric, which is the insulating material between the two metal electrodes. When voltage is applied, the capacitor stores energy in the electric field formed between the metal layers. The unique properties of metallized polypropylene make these capacitors very reliable and high performing.

Why Metallized Polypropylene Film Is Preferred as a Dielectric

Polypropylene is chosen because it has excellent electrical properties. It has a high dielectric constant, meaning it can store a lot of charge. It also has a very low dielectric loss, so it wastes little energy in heat. This makes metallized polypropylene capacitors very efficient.

The metal coating enables a self-healing effect. If a small short circuit happens inside, the metal around the fault evaporates, isolating the flaw and preventing total failure. This keeps capacitors safer and longer-lasting compared to other types.

Polypropylene films also tolerate high voltages and high temperatures well. They maintain stable performance even under harsh conditions. That’s why these capacitors are favored in critical applications, where reliability is key.

Advantages of Metallized Polypropylene Capacitors

- High capacitance: They provide large capacitance values relative to size.

- Low dielectric loss: Energy loss is minimal, which improves efficiency.

- Self-healing: Faults heal automatically, preventing damage spread.

- High voltage tolerance: Can handle hundreds or thousands of volts.

- Stable over time and temperature: Ensures consistent function in tough environments.

- Long lifespan: Rugged buildup means fewer failures and replacements.

These qualities make metallized polypropylene capacitors stand out for uses that demand precision and durability.

Typical Applications in Electronics and Energy

These capacitors appear across many industry sectors, including:

- Power electronics: Used in power supplies, inverters, and converters to smooth voltage and filter noise.

- Audio equipment: For noise reduction and signal clarity enhancement.

- Lighting circuits: Improve power factor and reduce harmonic distortion.

- Motor control: Enhance efficiency and reduce electromagnetic interference.

- Renewable energy systems: Stabilize power from solar and wind installations.

In automotive electronics, they play roles in battery management, engine control, and audio systems. Aerospace and military electronics also rely on them for their relationship of small size and secure operation.

| Приложение | Reason for Use | Benefit |

|---|---|---|

| Power Electronics | High voltage tolerance & low dielectric loss | Improved efficiency and noise reduction |

| Audio Equipment | Stable capacitance and low signal loss | Clearer sound |

| Renewable Energy | High reliability in variable conditions | Consistent power storage & flow |

| Automotive Electronics | Temperature & vibration resistance | Longer component life |

Selecting the Right Metallized Polypropylene Capacitor

Choosing the right capacitor involves considering:

| Factor | Importance |

|---|---|

| Capacitance | Must meet circuit’s energy storage needs |

| Voltage rating | Should exceed the system’s maximum voltage |

| Temperature range | Aligns with the operating environment |

| Size and form | Depends on space and mounting requirements |

| Tolerance | Specifies allowable variation in capacitance |

It's crucial to choose capacitors rated for expected stresses to avoid premature failure.

Best Practices for Storage, Handling, and Maintenance

Proper maintenance extends capacitor life. Here are key points:

- Storage:

- Keep capacitors in dry, cool places away from sunlight.

- Avoid exposure to heat and humidity.

- Handling:

- Avoid bending or crushing capacitors.

- Ensure correct polarity when connecting.

- Maintenance:

- Inspect regularly for physical damage like cracks or bulges.

- Test capacitance and leakage periodically.

- Replace capacitors showing signs of degradation or failure immediately.

Following these steps helps capacitors perform at peak levels throughout their service life.

Performance Compared to Other Capacitor Types

Metallized polypropylene capacitors often outperform aluminum electrolytic and ceramic types, thanks to:

| Feature | Metallized Polypropylene | Aluminum Electrolytic | Ceramic |

|---|---|---|---|

| Capacitance | High | Very High | Low to Medium |

| Dielectric Loss | Very Low | Moderate | Low |

| Voltage Range | High | Moderate to High | Low to Moderate |

| Self-Healing | Yes | No | No |

| Lifespan | Long | Short to Medium | Long |

| Temperature Stability | Very Good | Moderate | Good |

This makes metallized polypropylene capacitors excellent for precision and power applications that need stable, long-lasting components.

Troubleshooting and Recognizing Failures

Common signs that a metallized polypropylene capacitor may be failing include:

- Increased leakage current or capacitance loss.

- Visible swelling, cracking, or burnt marks on the casing.

- Circuit instability or noise spikes.

- Heat generation beyond normal levels.

In case of failure symptoms, tests with an LCR meter or ESR analyzer can confirm problems. Replace faulty capacitors promptly to avoid damage to other circuit elements. Early fault detection ensures long system uptime.

Metallized Polypropylene Capacitor Technical Comparison Table

| Attribute | Metallized Polypropylene | Aluminum Electrolytic | Ceramic |

|---|---|---|---|

| Dielectric Material | Polypropylene | Electrolyte | Ceramic |

| Self-Healing Capability | Yes | No | No |

| Max Voltage Rating | High (up to kV range) | Moderate | Low to Moderate |

| Dielectric Loss | Very Low | Moderate | Low |

| Lifespan | Long | Short to Medium | Long |

| Application Suitability | Precision electronics, power | General-purpose | High-frequency circuits |

Metallized polypropylene film capacitors bring exceptional effectiveness to many device needs. Understanding their construction, advantages, careful selection, and upkeep helps you get the most from these key components in electronics and power systems.

Conclusion

Market and Industry Trends in Metallized Polypropylene Films

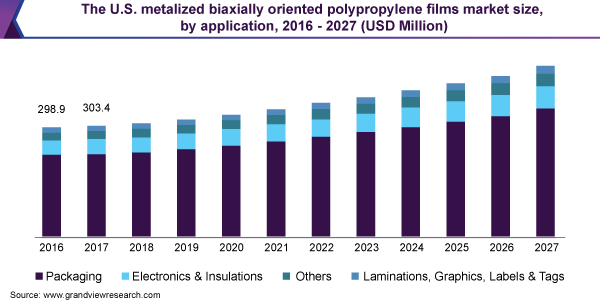

The market for metallized polypropylene films continues to grow driven by demand in packaging, electronics, automotive, and renewable energy sectors. Innovations in film thickness, metallization uniformity, and specialized coatings enable expanded applications and enhanced performance.

| Industry Sector | Growth Drivers | Key Application Areas |

|---|---|---|

| Упаковка | Food safety, sustainability, branding | Flexible packaging, labels |

| Электроника | Miniaturization, efficiency, and longevity | Capacitors, insulation |

| Автомобили | Electric vehicles, noise reduction | Capacitor components, insulation |

| Renewable Energy | Green energy adoption | Inverters, power control systems |

| Medical | Sterile packaging demand | Pharmaceutical seals, device packaging |

Continued investment in research and development ensures metallized polypropylene films remain vital to many innovative industries going forward.

FAQs about Examine various applications for metallized polypropylene films

In which industries are metallized polypropylene films used?

Metallized polypropylene films are used primarily in food and beverage packaging, electronics and electrical manufacturing, automotive, renewable energy, medical and pharmaceutical sectors, as well as consumer goods labeling and decorations.

How do metallized polypropylene films improve packaging performance?

Metallized polypropylene films improve packaging performance by providing excellent barrier protection against moisture, oxygen, and light, thereby extending product shelf life and ensuring food safety while offering a glossy, attractive appearance that enhances product appeal.

How do metallized polypropylene films enhance capacitor performance?

Metallized polypropylene films enhance capacitor performance by serving as a high-efficiency dielectric with low energy loss, offering self-healing properties to isolate faults, and maintaining stable electrical behavior under high voltage and temperature conditions, making capacitors reliable and long-lasting.

What benefits do metallized polypropylene films offer in electrical insulation and protection?

Metallized polypropylene films provide excellent electrical insulation and mechanical durability, protecting components from moisture, dust, temperature fluctuations, and preventing short circuits, which increases the reliability of electrical devices in automotive and industrial sectors.

What considerations should be made when selecting metallized polypropylene films for an application?

When selecting metallized polypropylene films, it is important to consider durability requirements, printability, temperature resistance, surface shape compatibility, and barrier needs to ensure the film’s performance matches the specific industrial application.

We covered what metallized polypropylene films are, how they’re made, and their key features. I explained their strong barrier, flexibility, and special coatings like aluminum. We saw why they stand out versus other plastics. Then, I showed their uses in packaging, electronics, and more, with tips on choosing the right type. Lastly, I detailed how these films boost capacitor performance and what care they need. Knowing these facts helps you pick the best film for your needs and keep your equipment working longer. Metallized polypropylene films really are smart, versatile materials.