What Are Metalized Films and Why Are They Important in Manufacturing?

When you hear about metalized films, think of a thin plastic sheet with a shiny metal layer on it. These films are made by coating a polymer base with a very thin layer of metal, usually aluminum. This metal layer is so thin you can see through it, yet it makes the film stronger and blocks moisture, oxygen, and light very well. This mix of materials gives metalized films a perfect balance of flexibility and protection.

What Are Metalized Films? Definition and Basic Composition

Metalized films are thin polymer films that have been coated with a metal layer. The coating is usually aluminum but can sometimes be chromium or other metals. The base films are often clear or white polymers like BOPP (Biaxially Oriented Polypropylene) or PET (Polyethylene Terephthalate).

- BOPP: Known for its toughness, clarity, and good heat resistance.

- PET: Strong, lightweight, and has excellent chemical and dimensional stability.

The metal coating is applied in layers only a few nanometers thick. This thin metal layer sticks firmly to the polymer surface to enhance properties without changing the film's flexibility or weight.

Key Materials Used: Polymer Substrates and Metals

| Material Type | Examples | Features |

|---|---|---|

| Polymer Films | BOPP, PET | Flexible, heat-stable, strong |

| Metals | Aluminum, Chromium | Reflective, barrier against gas and moisture |

The polymer forms the flexible base, while the metal adds strength, barrier properties, and a shiny, metallic look. Aluminum is the most common metal because it is cheap, easy to deposit, and offers high barrier protection. Chromium may be used in some niche applications for its corrosion resistance.

Functions and Benefits: Barrier Properties, Aesthetic Appeal, Shelf Life Extension

Metalized films provide several vital benefits in manufacturing:

- Barrier Properties: They block moisture, oxygen, and light better than plain polymers. This is crucial to keep food and goods fresh.

- Aesthetic Appeal: The shiny, metallic surface improves product look. It's popular for luxury packaging because it catches the eye.

- Shelf Life Extension: By reducing exposure to oxygen and moisture, products last longer, reducing waste.

These qualities make metalized films ideal for keeping perishable products safe and appealing.

Common Applications in Manufacturing

Metalized films have uses across many industries:

- Food Packaging: Chips, snacks, coffee, tea, and other perishables benefit from extended freshness.

- Labels: Self-adhesive metalized films give a premium finish for cosmetics and beverage bottles.

- Insulation: Reflective surfaces reduce heat transfer in construction, automotive, and aerospace parts.

- Electronics: Used for EMI shielding and antistatic packaging.

Some specific film types include:

- Metalized Barrier Films: Provide strong protection for food and pharmaceutical packaging.

- Metalized PSL Films: Share adhesive backing ideal for labels and prints.

- Metalized Wrap Around Label Films: A BOPP film metalized on one side for stiffness and heat sealability.

Metalized Films vs. Aluminum Foil and Foil Laminates

Metalized films often replace heavier aluminum foils when weight and cost are concerns.

| Feature | Metalized Films | Aluminum Foil | Foil Laminates |

|---|---|---|---|

| Weight | Very light | Heavier | Heavy (multi-layer) |

| Cost | Lower | Higher | Highest |

| Flexibility | High | Lower | Medium |

| Barrier Properties | Good | Excellent | Excellent |

| Aesthetic Appeal | Shiny metallic look | Shiny metallic look | Varies |

| Heat Sealability | Excellent | Poor (requires lamination) | Excellent |

While aluminum foil has superior barrier protection, metalized films balance price, performance, and flexibility for many uses.

Global and Indian Market Trends in Metalized Films Manufacturing

The metalized film packaging market is growing fast worldwide, and India is no exception. The Indian metalized film industry is projected to grow at a Compound Annual Growth Rate (CAGR) of about 26.7% over the next five years. This growth stems from the increasing demand for food safety and contamination-free packaging.

Globally, the trend is toward:

- Higher barrier films to extend shelf life.

- More eco-friendly options like oxo-biodegradable metalized films.

- Advanced printing compatibility to support branding on packaging.

In India, metalized films are widely used in snacks, pharmaceuticals, cosmetics, and beverage markets. New product varieties such as Metalized Cavitated White Opaque Film and Metalized Oxo-Biodegradable Heat Sealable Film are gaining ground for their unique benefits.

Environmental Considerations and Recent Innovations

Metalized films help reduce food waste by extending shelf life, which is an environmental plus. However, their metal layer can make recycling tougher. To address this, companies are innovating:

- Oxo-biodegradable metalized films that break down faster in the environment.

- Solvent-free coatings used in Metalized Barrier Films reduce harmful emissions.

- Composite films combining metal layers with biodegradable polymers.

These changes aim to balance performance needs and reduce environmental impacts while maintaining the excellent barrier and aesthetic qualities metalized films offer.

Metalized films combine a thin metal layer and strong polymer base to create flexible, shiny films. They provide strong barriers, extend product shelf life, and add aesthetic appeal. Used widely in food, labels, electronics, and insulation, these films compete well with foil while being lighter and cost-effective. With rapid market growth, especially in India, and innovations in eco-friendliness, metalized films remain vital in modern manufacturing.

What Are the Principal Methods Used in Manufacturing Metalized Films?

Metalized films find wide use, especially in packaging, thanks to their shiny appearance and strong barrier properties. To make these films, manufacturers use several methods. The main methods of manufacturing metalized films include vacuum metallization, sputtering, chemical deposition, and roll-to-roll coating. Each method has unique steps, equipment, and outcomes. Let's explore each in detail to understand how metalized films are made and which method suits different needs best.

What is Vacuum Metallization? Process Description, Equipment Used, and Controlling Parameters

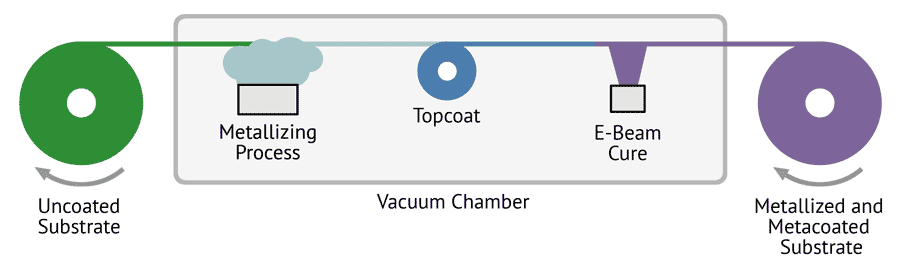

Vacuum metallization is the most common method to produce metalized films, especially aluminum-coated films like metalized BOPP or PET. The process happens under a high vacuum to ensure metal vapor flows without air interference.

How it works: Polymer film rolls (such as BOPP or PET) unwind and pass through a vacuum chamber. Inside this chamber, aluminum is heated in a crucible or boat until it vaporizes. The metal vapor travels in a straight line and deposits evenly on the cold polymer film surface.

Equipment used:

- Vacuum chamber with pressure around 10^-5 to 10^-6 Torr

- Heating source (usually resistance or electron beam evaporators)

- Film unwind and rewind rolls

- Thickness monitor sensors

Controlling parameters:

- Chamber vacuum level

- Metal evaporation rate (controlled by heater power)

- Film speed through the chamber (controls coating thickness)

- Distance from metal source to film surface

The metal layer deposited via vacuum metallization is very thin—typically 20 to 100 nanometers. This thin coating provides high reflectivity and excellent moisture and oxygen barrier properties without affecting film flexibility.

Vacuum metallization is popular because it produces uniform metal layers at high speeds. It's widely used for food packaging films, decorative labels, and insulation films.

How Does Sputter Coating Work in Metalized Film Production? Ion Bombardment Principles and Advantages

Sputter coating offers a different way to deposit metal on films by using ion bombardment to knock metal atoms off a target. This method gives more control over metal film properties.

Process overview: Inside a sputtering chamber filled with argon gas, a metal target (like aluminum) is bombarded by argon ions generated by plasma. These ions physically knock metal atoms off the target. The metal atoms then land on the moving polymer film and form a thin metal layer.

Equipment details:

- Vacuum sputtering chamber maintained at low pressure (~10^-3 Torr)

- Magnetron cathodes for metal target excitation

- Plasma generation system

- Roll-to-roll film handling system

Advantages:

- Better adhesion of metal to polymer due to ion energy

- Can deposit metals that are hard to vaporize by evaporation

- Fine control over coating thickness and density

- Can produce multi-metal layers or alloys in one process

Sputtering works well for films requiring high barrier performance and durability. It is used in electronics packaging and specialty films for heat and corrosion resistance.

What Role Does Chemical Vapor Deposition (CVD) or Chemical Deposition Play? Process Overview and Typical Use Cases

Chemical deposition methods, including chemical vapor deposition (CVD), differ from physical methods like vacuum metallization and sputtering. Instead of evaporating or knocking off metal atoms, they use chemical reactions to deposit metal atoms onto films.

Process basics: In CVD, metal-containing gases or precursors enter a reaction chamber where heat or plasma triggers a chemical reaction. This reaction produces metal atoms or compounds that settle on the film surface, forming a thin, uniform metal or metal-oxide layer.

Typical processes:

- Thermal CVD: heats substrates to trigger reactions

- Plasma-enhanced CVD: uses plasma to lower reaction temperatures

- Atomic layer deposition (ALD): deposits atomic layers one at a time for precise control

Use cases: CVD is ideal for depositing very thin films with precise thickness for applications needing excellent barrier properties and stable coatings. It's popular in electronics, optical films, and some flexible packaging where tight control over film quality is crucial.

However, CVD is slower and more complex compared to vacuum metallization or sputtering, limiting its use in mass high-speed packaging film production.

How is Roll-to-Roll Coating Integrated into Mass Production of Metalized Films? Benefits for Scalability and Uniformity

Roll-to-roll (R2R) coating is a manufacturing technique that enables continuous processing of flexible films. It integrates coating, drying, and metallizing steps for high-volume production.

Integration with metalizing methods: Both vacuum metallization and sputtering systems can be designed for roll-to-roll operation. Film unwinds from a roll, passes through metal deposition chambers, and rewinds, allowing large-scale manufacturing.

Steps in R2R coating:

- Unwinding: Film roll is fed into the system.

- Cleaning: Film surface may be plasma-treated for better adhesion.

- Metal deposition: Film passes through vacuum metallization or sputtering chambers.

- Post-treatment: Coated film may receive protective coatings or be laminated.

- Rewinding: Finished film winds for further processing or cutting.

Benefits of roll-to-roll coating:

- Continuous process reduces production time

- High throughput suitable for large volume demands

- Uniform metal layer thickness across broad film widths

- Cost efficiency due to automation and reduced labor

- Flexibility to combine metalization with other coatings or printing inline

Roll-to-roll coating is vital for meeting the growing metalized films demand in packaging sectors, especially in markets like India experiencing rapid growth powered by food safety needs.

Comparison of Thickness Control, Adhesion, and Uniformity Among Different Metalizing Methods

| Method | Thickness Control | Adhesion to Polymer | Uniformity | Typical Thickness (nm) |

|---|---|---|---|---|

| Vacuum Metallization | Good – by speed & time | Moderate | High | 20 – 100 |

| Sputtering | Excellent – plasma power & time | Excellent – ion energy bonds metals | Very high | 10 – 200 |

| Chemical Deposition | Superior – atomic level | Excellent | Excellent | <10 – 100 |

| Roll-to-Roll Setup | Depends on base method | Same as base method | Excellent | Varies by process |

Vacuum metallization offers good thickness control and uniformity with moderate adhesion. Sputtering improves adhesion and allows thicker films. Chemical deposition offers ultimate control but is slower. Roll-to-roll setups enhance uniformity and throughput but depend on the underlying metalizing technology.

Material Compatibility and Limitations of Each Method for Various Polymers and Metals

- Vacuum metallization suits polymers like BOPP, PET, and nylon. It's mainly used for aluminum but can apply chromium or nickel. However, adhesion can be low on unprimed surfaces.

- Sputtering works well on heat-sensitive polymers due to lower temperatures. It deposits various metals, including silver and copper, expanding film functions.

- Chemical deposition is compatible with many substrates, including complex shapes, but polymer surface pre-treatment may be needed.

- All methods require clean, smooth films for best results. Some polymers might degrade under plasma or heat exposure during deposition.

Energy Consumption and Environmental Impact Considerations for Each Manufacturing Technique

- Vacuum metallization involves energy use mainly in vacuum pumps and heaters. It is relatively energy-efficient and produces minimal waste.

- Sputtering requires plasma generation, which uses more electricity. High vacuum and gas use increase energy footprint.

- Chemical deposition often needs high temperatures and reactive chemicals, causing higher energy consumption and some waste chemicals.

- Roll-to-roll setups improve energy efficiency by continuous processing and reduced handling. Inline recycling of scrap reduces waste.

Environmentally, solvent-free methods like vacuum metallization and sputtering are preferred over solvent-based coating methods. Ongoing research focuses on lowering energy use and adopting biodegradable films with metal layers.

By detailing the various methods used in manufacturing metalized films, it's clear that each offers unique features. Vacuum metallization and sputtering lead mass production with excellent barrier films, while chemical deposition serves niche, high-precision needs. Roll-to-roll coating ties the process together for speed and uniformity, supporting booming markets and packaging innovation.

What Are the Applications and Industry-Specific Considerations of Metalized Films?

Metalized films play a key role in many industries, especially packaging. Their unique properties and versatility make them popular for food, beverage, pharmaceutical, and cosmetic packaging. They also serve well in electronics and insulation. Let me take you through how these films work in various applications, what makes them special, and the factors you should consider when using them.

How Different Metalized Films Support Packaging Needs

There are different types of metalized films designed to match specific packaging needs:

- Metalized Barrier Films: These films have multiple layers and provide excellent protection against moisture, oxygen, and light. They are widely used for products that need a long shelf life, like coffee, tea, and pharmaceutical items.

- Metalized Pressure-Sensitive LabelStock (PSL) Films: These films come with adhesive backing. They print well using flexography, UV, letterpress, and offset. You find them on luxury cosmetics and beverage bottles.

- Metalized Wrap Around Label Films: Made from BOPP (biaxially oriented polypropylene), these films have a metalized side and a heat-sealable side. They look crisp white and offer excellent stiffness and adhesion. They are popular for beverages and pharmaceutical bottles.

Each film type supports packaging by providing tough barriers against environmental threats while allowing flexible printing and finishing options.

What Properties Make Metalized Films Suitable for Food, Beverage, Pharmaceutical, and Cosmetic Packaging?

Metalized films share several important properties that suit packaging in these sectors:

- Moisture Barrier: Keeps products dry and fresh.

- Oxygen Barrier: Prevents oxidation that spoils food and drugs.

- Light Barrier: Blocks harmful UV rays that degrade sensitive goods.

- Heat Sealability: Allows tight, tamper-evident seals.

- Chemical Resistance: Protects against oils, solvents, and cleaning agents.

- Printability: Offers vibrant, metallic finishes that boost brand appeal.

The thin aluminum layer on the polymer film acts as the shield, providing low permeability to gases and moisture. This helps keep products safe while enhancing shelf appeal.

How Metalized Films Enhance Shelf Life and Product Protection

Shelf life can increase dramatically with metalized films because they block moisture, oxygen, and light—all major causes of spoilage.

| Barrier Type | Impact on Shelf Life | Example |

|---|---|---|

| Moisture | Prevents mold and sogginess | Snack foods, baked goods |

| Oxygen | Slows oxidation and nutrient loss | Coffee, dried fruits |

| Light | Blocks UV rays that damage vitamins | Pharmaceuticals, cosmetics |

Metalized films also resist harsh temperatures and abrasion. This means products stay protected during rough shipping and handling.

How Metalized Films Contribute to Product Aesthetics and Branding

The metallic finish gives packages a standout, shiny look that draws consumer attention. Brands use this finish to suggest quality and innovation. Plus, these films allow various printing methods:

- Flexography

- UV curing

- Letterpress

- Offset printing

This versatility lets labels feature bold colors, fine details, and metallic highlights, enhancing branding—even on flexible packaging.

Machinability and Lamination Compatibility Considerations

In production lines, metalized films must run smoothly to avoid costly downtime. They are compatible with common technologies like:

- Horizontal Form Fill Seal (HFFS): Good for pouches and sachets.

- Vertical Form Fill Seal (VFFS): Used for items like chips and snacks.

Their excellent heat sealability suits duplex or triplex laminates. Films like metalized barrier films often come solvent-free coated, perfect for sandwich lamination. This ensures strong bonds without damaging the metallic layer.

Application in Electronics and Insulation

Outside packaging, metalized films shine in electronic and insulation uses:

- EMI Shielding: The metal layer blocks electromagnetic interference, protecting sensitive circuits.

- Heat Reflectivity: Reflects radiant heat, helping insulate buildings, vehicles, and equipment.

- Flexible Circuitry: Lightweight films with metal coatings work as conductive pathways.

- Antistatic Packaging: Prevents static buildup in electronics shipping.

These benefits expand metalized films’ reach into automotive, aerospace, and industrial fields.

Emerging Industry Trends: Biodegradable Metalized Films and Solvent-Free Coatings

The demand for greener packaging drives innovation. New metalized films feature:

- Biodegradable substrates: Films that break down naturally after use.

- Oxo-biodegradable heat sealable films: Which reduce plastic pollution.

- Solvent-free coatings: Reduce harmful emissions during production, making films more eco-friendly.

These trends promise to cut environmental impact without sacrificing performance.

Challenges in Metalized Film Usage

Metalized films do face some challenges:

- Pinholes: Tiny holes can form during metalizing, reducing barrier quality.

- Durability: Repeated handling might wear the metal layer, lowering protection.

- Barrier Limitations: While better than non-metallic films, metalized films usually don’t match the barrier strength of aluminum foil laminates.

Understanding these limits helps manufacturers choose the right film type for each product.

Summary of Key Metalized Film Applications and Advantages

| Application Area | Advantages |

|---|---|

| Еда и напитки | Extended shelf life, moisture and oxygen barrier, attractive metallic look |

| Pharmaceuticals | Protection from light and gases, chemical resistance, tamper-evident seals |

| Cosmetics | Upscale finish, print versatility, UV and moisture protection |

| Electronics & Insulation | EMI shielding, heat reflectivity, static control |

By selecting appropriate metalized films, industries gain better product protection, longer freshness, and enhanced brand appeal. Their growing role is clear as markets expand, especially in countries like India, where demand for safe packaging rises at nearly 27% CAGR over five years.

FAQs about Detail the various methods used in manufacturing metalized films

What are the principal methods used in manufacturing metalized films?

The principal methods used in manufacturing metalized films are vacuum metallization, sputtering, chemical deposition, and roll-to-roll coating, each offering unique advantages in adhesion, thickness control, and production speed.

How does vacuum metallization work in metalized film production?

Vacuum metallization works by vaporizing metal, usually aluminum, in a high-vacuum chamber where the metal vapor deposits evenly onto a moving polymer film, creating a thin reflective and barrier layer without affecting flexibility.

What is sputter coating and what benefits does it provide in metalized films?

Sputter coating employs ion bombardment to eject metal atoms from a target onto polymer films, providing superior adhesion, controlled thickness, and the ability to deposit metals difficult to vaporize, ideal for high-barrier and durable films.

How does chemical vapor deposition differ from physical coating methods in metalized films?

Chemical vapor deposition deposits metal atoms via chemical reactions from metal-containing gases, enabling atomic-level thickness control and highly uniform, stable coatings, though it operates slower and is typically used for specialty electronic and optical films.

What advantages does roll-to-roll coating offer in the mass production of metalized films?

Roll-to-roll coating offers continuous processing, improving throughput, uniformity, and cost efficiency by integrating cleaning, metal deposition, and post-treatment steps in a streamlined setup ideal for

Metalized films are key materials that offer strong barriers and eye-catching looks. Using metals like aluminum on plastic films helps protect products and extend shelf life. Manufacturing methods such as vacuum metallization and roll-to-roll coating create uniform, high-quality films. Their use spans food, electronics, and cosmetics, with growing focus on eco-friendly options. As an expert, I see metalized films as vital to modern packaging and manufacturing. They balance function and style while evolving with new tech and environmental needs. Understanding them can help businesses choose the right film for every product.