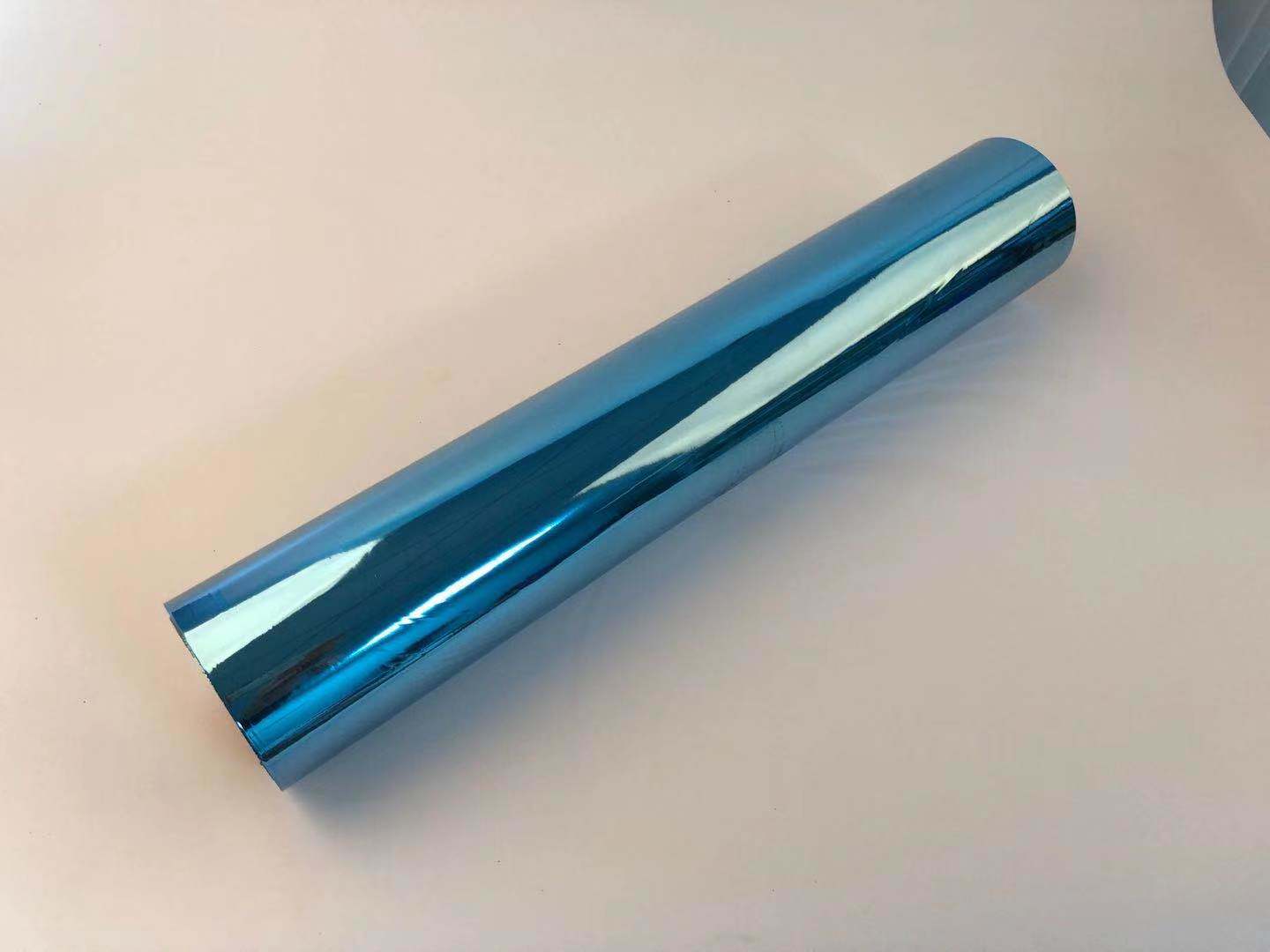

Metalized pe film

| Product | PET Metallized Film |

| Material | PET + color+ aluminum layer / PET + aluminum + color layer |

| Thickness | 12~188um |

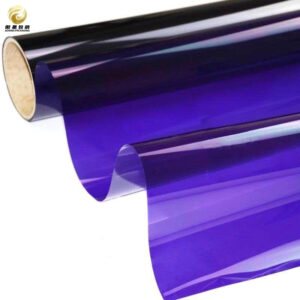

| Color Option | Red,Blue,Purple,Green,Gold,Yellow,Rose,Rainbow,etc. |

| Width & Length | Width:500~1800mm Length:Customized |

Detailed Descriptions

Product Description: Metalized PE Film

Introducing our premium Metalized PE Film, a versatile and high-performance packaging solution designed to meet the diverse needs of various industries. This innovative film combines the durability of polyethylene (PE) with a sophisticated metalized layer, resulting in a product that not only enhances visual appeal but also significantly improves barrier properties.

Key Features:

1. Superior Barrier Protection: The metalized layer provides exceptional resistance to moisture, oxygen, and light, making it an ideal choice for products that require extended shelf life and protection from environmental factors. This feature is particularly beneficial for food packaging, pharmaceuticals, and sensitive electronic components.

2. Enhanced Aesthetic Appeal: The reflective surface of the metalized film adds a touch of elegance and sophistication to any product. Its shiny finish can elevate branding efforts by creating eye-catching packaging that stands out on retail shelves, attracting consumer attention and driving sales.

3. Lightweight and Flexible: Our Metalized PE Film is lightweight yet robust, allowing for easy handling and application in various packaging processes. Its flexibility ensures compatibility with different packaging machinery, making it suitable for both manual and automated operations.

4. Eco-Friendly Options Available: We understand the importance of sustainability in today’s market. Our Metalized PE Film can be produced using recyclable materials, aligning with eco-conscious practices while maintaining high performance standards.

5. Customizable Solutions: We offer a range of thicknesses, widths, and finishes to cater to specific customer requirements. Whether you need a film for food packaging, cosmetic products, or industrial applications, our team is ready to collaborate with you to develop tailored solutions that meet your unique needs.

6. Temperature Resistance: Designed to withstand a wide range of temperatures, our Metalized PE Film is suitable for both hot fill and cold storage applications. This versatility ensures that your products remain protected regardless of the conditions they encounter during transportation or storage.

7. Cost-Effective Packaging Solution: By combining excellent barrier properties with aesthetic appeal at an economical price point, our Metalized PE Film offers an outstanding return on investment for businesses looking to enhance their packaging without compromising quality.

Applications:

Our Metalized PE Film is ideal for a variety of applications across multiple sectors:

– Food Packaging: Perfect for snacks, confectionery items, and ready-to-eat meals where freshness is paramount. – Pharmaceuticals: Provides essential protection for medications and health supplements against moisture and light degradation. – Cosmetics & Personal Care: Enhances product presentation while safeguarding sensitive formulations from environmental exposure. – Industrial Uses: Suitable for packaging electronic components or other sensitive materials requiring protection from moisture and dust.

As a reputable manufacturer with years of experience in the industry, we understand the importance of quality and reliability. Our Metalized PE Film is produced using advanced technology and high-quality raw materials, ensuring that it meets international standards for performance and safety. We cater to businesses looking to bulk buy this product at competitive wholesale prices, allowing you to optimize your procurement process while maintaining quality.

Our commitment to excellence extends beyond just manufacturing; we are also a trusted exporter of Metalized PE Film to various markets around the globe. By choosing us as your OEM partner, you can benefit from customized solutions tailored to your specific requirements. Whether you need unique dimensions, thicknesses, or finishes, our team is dedicated to providing you with the best options available.

For businesses seeking bulk pricing options, we offer attractive bulk price arrangements that ensure you receive the best value for your investment. Our extensive experience as a supplier allows us to streamline the purchasing process, making it easier for you to acquire high-quality Metalized PE Film in large quantities without compromising on quality or service.

In summary, our Metalized PE Film stands out as a top choice for companies looking for reliable packaging solutions. With our strong presence as a manufacturer in China and our commitment to quality as an exporter and supplier, we are well-equipped to meet your needs. Contact us today to learn more about how we can support your business with our exceptional products and services.