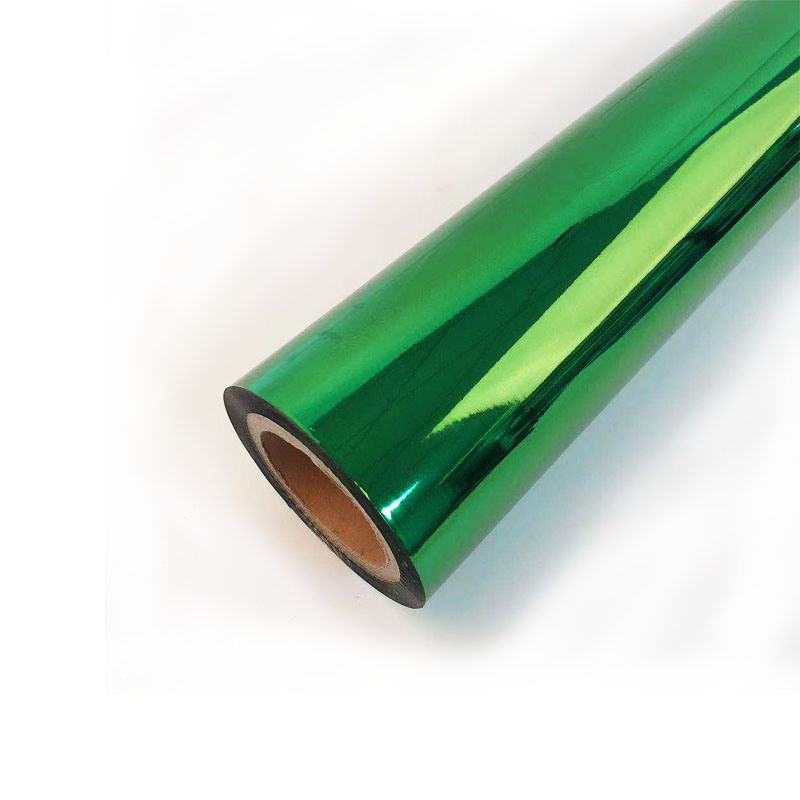

metalized mylar film

| Product | PET Metallized Film |

| Material | PET + color+ aluminum layer / PET + aluminum + color layer |

| Thickness | 12~188um |

| Color Option | Red,Blue,Purple,Green,Gold,Yellow,Rose,Rainbow,etc. |

| Width & Length | Width:500~1800mm Length:Customized |

Detailed Descriptions

Product Description: Metalized Mylar Film

Introducing our premium Metalized Mylar Film, a versatile and high-performance material designed to meet the demanding needs of various industries. This innovative film combines the exceptional properties of Mylar with a sophisticated metalized layer, resulting in a product that offers superior durability, reflectivity, and barrier protection.

Key Features:

1. Exceptional Barrier Properties: Our Metalized Mylar Film provides an outstanding barrier against moisture, gases, and light. This makes it an ideal choice for packaging sensitive products such as food items, pharmaceuticals, and electronics, ensuring prolonged shelf life and maintaining product integrity.

2. High Reflectivity: The metalized surface of the film reflects up to 90% of light, making it an excellent option for applications requiring thermal insulation or light reflection. This feature is particularly beneficial in horticulture, where it can enhance plant growth by maximizing light exposure.

3. Durability and Strength: Engineered for resilience, our Metalized Mylar Film exhibits remarkable tensile strength and tear resistance. It withstands harsh environmental conditions without compromising its structural integrity, making it suitable for both indoor and outdoor applications.

4. Versatile Applications: This film is not only perfect for packaging but also finds extensive use in insulation materials, emergency blankets, decorative items, and even as a component in electronic devices. Its adaptability makes it a valuable asset across various sectors including agriculture, aerospace, automotive, and consumer goods.

5. Easy to Work With: Available in various thicknesses and widths, our Metalized Mylar Film can be easily cut, shaped, or laminated to fit specific project requirements. Its lightweight nature allows for effortless handling and application.

6. Eco-Friendly Options: We are committed to sustainability; therefore, our Metalized Mylar Film is available in eco-friendly variants that minimize environmental impact while maintaining high performance standards.

Specifications:

– Material: High-quality Mylar with metalized coating – Thickness: Customizable options available (typically ranging from 12 to 50 microns) – Width: Available in rolls up to 60 inches wide – Color: Silver (standard), with custom colors available upon request – Temperature Resistance: Suitable for temperatures ranging from -40°C to +120°C

Conclusion:

As a reputable manufacturer, we understand the importance of quality and reliability. Our Metalized Mylar Film is produced using advanced technology and stringent quality control measures, ensuring that each roll meets the highest industry standards. This commitment to excellence has established us as a trusted exporter in the global market.

For businesses looking to optimize their supply chain, we offer competitive bulk prices for our Metalized Mylar Film. Whether you are interested in bulk buying for large-scale projects or seeking wholesale options for retail distribution, we can accommodate your needs with flexible order quantities. Our OEM services allow you to customize specifications to align with your unique requirements, ensuring that you receive a product tailored specifically for your application.

As a dedicated supplier, we are committed to providing exceptional customer service and support throughout your purchasing journey. Our knowledgeable team is available to assist you with any inquiries regarding our Metalized Mylar Film, including technical specifications and pricing options.

Choose us as your reliable partner in sourcing high-quality Metalized Mylar Film from China. With our extensive experience as an exporter and commitment to customer satisfaction, we are confident that our products will exceed your expectations. Contact us today to learn more about how we can support your business with our premium Metalized Mylar Film solutions at competitive bulk prices.