Holographic Lamination Film

| Product | Transparent PET Film |

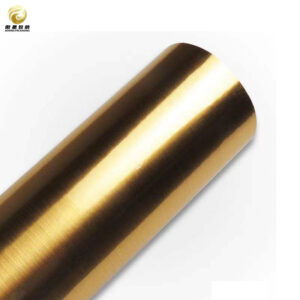

| Material | PET + color+ aluminum layer / PET + aluminum + color layer |

| Thickness | 12~188um |

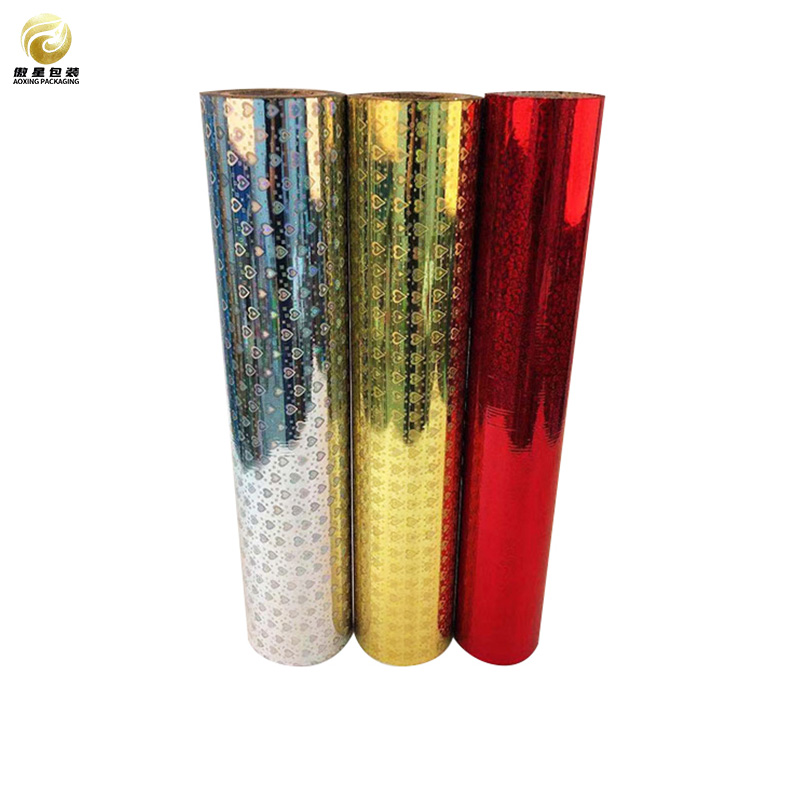

| Color Option | Red,Blue,Purple,Green,Gold,Yellow,Rose,Rainbow,etc. |

| Width & Length | Width:500~1800mm Length:Customized |

Detailed Descriptions

Product Description: Holographic Lamination Film

Elevate your packaging and print projects with our premium Holographic Lamination Film, a cutting-edge solution designed to add a stunning visual dimension to your materials. This innovative film combines the protective qualities of traditional lamination with an eye-catching holographic finish, making it an ideal choice for brands looking to stand out in a competitive marketplace.

Key Features:

1. Striking Visual Appeal: The holographic effect creates a dynamic interplay of light and color, ensuring that your printed materials capture attention from every angle. Whether used on product packaging, promotional materials, or business cards, this film enhances the aesthetic appeal and elevates the perceived value of your brand.

2. Durability and Protection: Our Holographic Lamination Film is engineered to provide superior protection against scratches, moisture, and UV light. This durability ensures that your printed materials maintain their vibrant appearance over time, making them suitable for both indoor and outdoor applications.

3. Versatile Applications: This lamination film is compatible with a wide range of substrates, including paper, cardboard, and synthetic materials. It is perfect for use in various industries such as cosmetics, food and beverage, retail packaging, and promotional items. The versatility of this film allows you to unleash your creativity across multiple projects.

4. Easy Application: Designed for seamless integration into existing printing processes, our Holographic Lamination Film can be applied using standard laminating machines or through cold lamination techniques. Its user-friendly nature ensures that even those new to lamination can achieve professional results with ease.

5. Eco-Friendly Options Available: We understand the importance of sustainability in today’s market. Our Holographic Lamination Film is available in eco-friendly options that meet industry standards for environmental responsibility without compromising on quality or performance.

6. Customizable Solutions: We offer a variety of holographic patterns and finishes to suit your specific branding needs. From subtle iridescent effects to bold geometric designs, our customizable solutions allow you to create unique packaging that reflects your brand identity.

Applications:

– Product Packaging: Enhance the shelf appeal of your products with holographic finishes that attract consumers’ attention. – Marketing Materials: Create captivating brochures, flyers, and posters that leave a lasting impression on potential clients. – Business Cards: Stand out in networking situations with business cards that showcase your brand’s creativity and professionalism. – Event Invitations: Make special occasions unforgettable with invitations that shimmer and shine.

Conclusion:

Our Holographic Lamination Film is perfect for businesses looking to enhance their product presentation with eye-catching designs that capture attention. The unique holographic effects not only add a layer of sophistication but also provide protection against wear and tear, making it an ideal choice for various applications, including packaging, labels, and promotional materials.

As a trusted manufacturer with years of experience, we understand the importance of reliability and consistency in supply. We offer competitive bulk prices for those looking to bulk buy our Holographic Lamination Film, ensuring that you receive the best value without compromising on quality. Our wholesale options are designed to accommodate businesses of all sizes, from small enterprises to large corporations.

We also provide OEM services tailored to your specific requirements, allowing you to customize the film according to your branding needs. Whether you are looking for unique patterns or specific dimensions, our team is dedicated to working closely with you to deliver a product that aligns perfectly with your vision.

Partnering with us means choosing a reputable producer committed to excellence in every aspect of production and service. Our extensive experience as an exporter enables us to efficiently handle international orders while ensuring timely delivery.

In summary, our Holographic Lamination Film is not just a product; it’s an investment in quality and aesthetics that will set your brand apart in the marketplace. Contact us today to learn more about our offerings and how we can support your business needs with our exceptional products at competitive bulk prices.