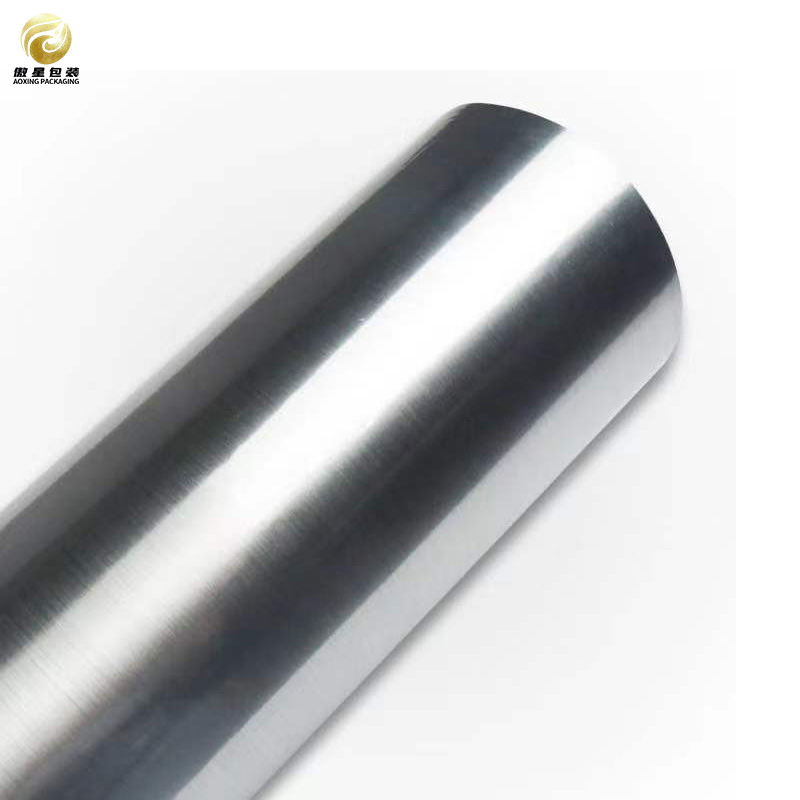

Brushed Surface PET Film

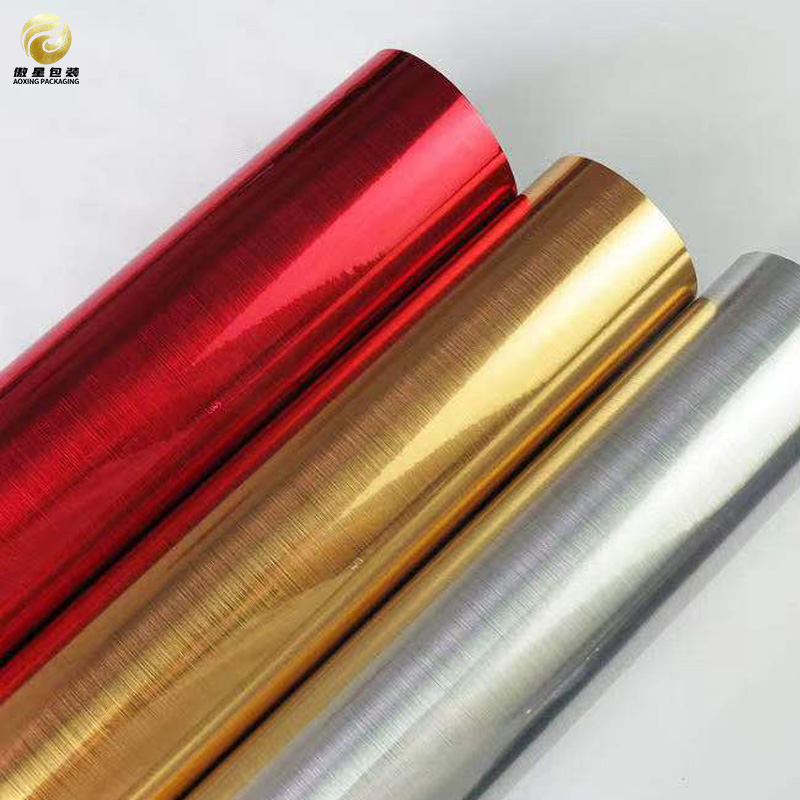

| Product | Brushed PET Film |

| Material | PET + color+ aluminum layer / PET + aluminum + color layer |

| Thickness | 12~188um |

| Color Option | Red,Blue,Purple,Green,Gold,Yellow,Rose,Rainbow,etc. |

| Width & Length | Width:500~1800mm Length:Customized |

Detailed Descriptions

Product Description: Brushed Surface PET Film

Introducing our premium Brushed Surface PET Film, a versatile and high-performance material designed to meet the demanding needs of various industries. Engineered from high-quality polyethylene terephthalate (PET), this film combines durability with an aesthetically pleasing brushed texture, making it an ideal choice for applications where both functionality and visual appeal are paramount.

Key Features:

1. Superior Durability: Our Brushed Surface PET Film is crafted to withstand the rigors of daily use. Its robust construction ensures resistance to scratches, abrasions, and environmental factors, making it suitable for both indoor and outdoor applications.

2. Elegant Aesthetic: The unique brushed surface finish provides a sophisticated look that enhances the visual appeal of any product. This film is perfect for applications in consumer electronics, automotive interiors, packaging, and more, where a refined appearance is essential.

3. Excellent Clarity and Transparency: Despite its textured surface, this PET film maintains exceptional clarity and transparency. This feature allows for vibrant colors and intricate designs to shine through, making it an excellent choice for graphic overlays and decorative applications.

4. Easy Processing: Our Brushed Surface PET Film is designed for ease of use in various manufacturing processes. It can be easily cut, shaped, and adhered to different substrates without compromising its integrity or performance.

5. Chemical Resistance: This film exhibits remarkable resistance to a wide range of chemicals, ensuring longevity even in challenging environments. It is particularly suitable for applications involving exposure to oils, solvents, and other harsh substances.

6. Eco-Friendly Option: Made from recyclable materials, our Brushed Surface PET Film aligns with sustainable practices. By choosing this product, you contribute to reducing environmental impact while enjoying high-quality performance.

Applications:

The versatility of our Brushed Surface PET Film makes it suitable for a broad spectrum of applications across multiple industries:

– Consumer Electronics: Ideal for protective covers and decorative overlays on devices such as smartphones, tablets, and laptops. – Automotive Industry: Perfect for interior trim components that require both durability and an upscale finish. – Packaging Solutions: Enhances product packaging with its elegant appearance while providing protection against damage. – Signage and Displays: Suitable for creating eye-catching graphics that require both durability and aesthetic appeal. – Home Décor: Can be used in various home improvement projects where a stylish finish is desired.

Conclusion:

As a trusted supplier and manufacturer, we take pride in offering our Brushed Surface PET Film in bulk quantities, making it an ideal choice for businesses looking to bulk buy for their production needs. Our commitment to quality and customer satisfaction has established us as a prominent exporter in the global market, providing businesses with reliable solutions tailored to their specifications.

This film features a unique brushed texture that not only enhances its aesthetic appeal but also provides excellent resistance to scratches and wear. It is perfect for applications ranging from packaging to decorative surfaces, making it a preferred choice among various sectors. Our OEM services allow you to customize the film according to your specific requirements, ensuring that you receive a product that aligns perfectly with your brand’s vision.

When you choose our Brushed Surface PET Film, you benefit from competitive bulk prices without compromising on quality. We understand the importance of cost-effective solutions in today’s market, which is why we offer wholesale options designed to accommodate businesses of all sizes.

Partner with us for your Brushed Surface PET Film needs and experience the reliability of a dedicated producer committed to excellence. Whether you are looking for standard sizes or custom specifications, our team is here to assist you every step of the way. Contact us today to learn more about how we can support your business with our exceptional products and services.