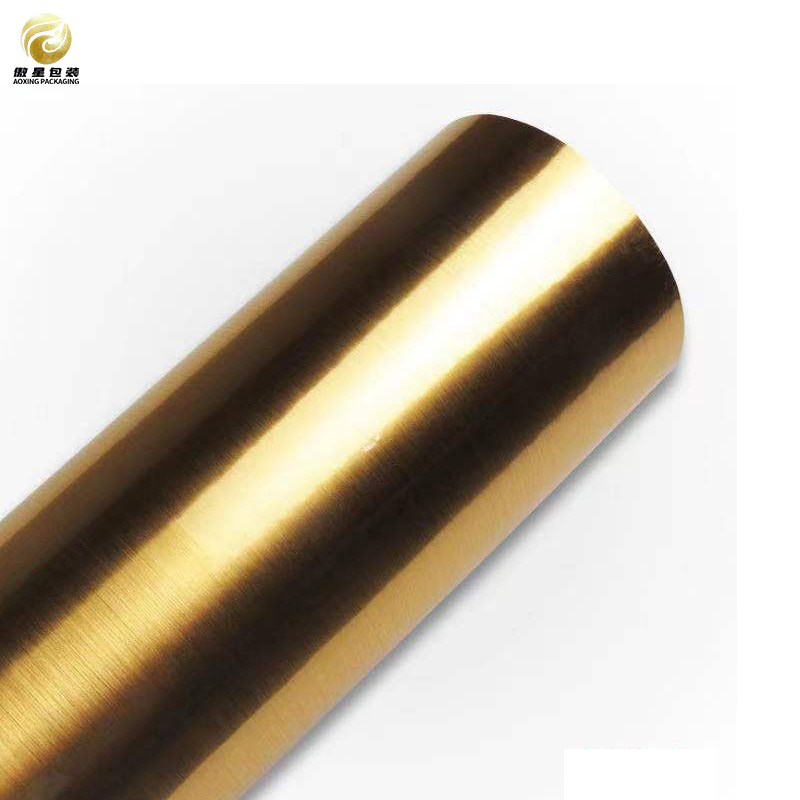

Metallic Finish PET Film

| Product | PET Brushed Film |

| Material | PET + color+ aluminum layer / PET + aluminum + color layer |

| Thickness | 12~188um |

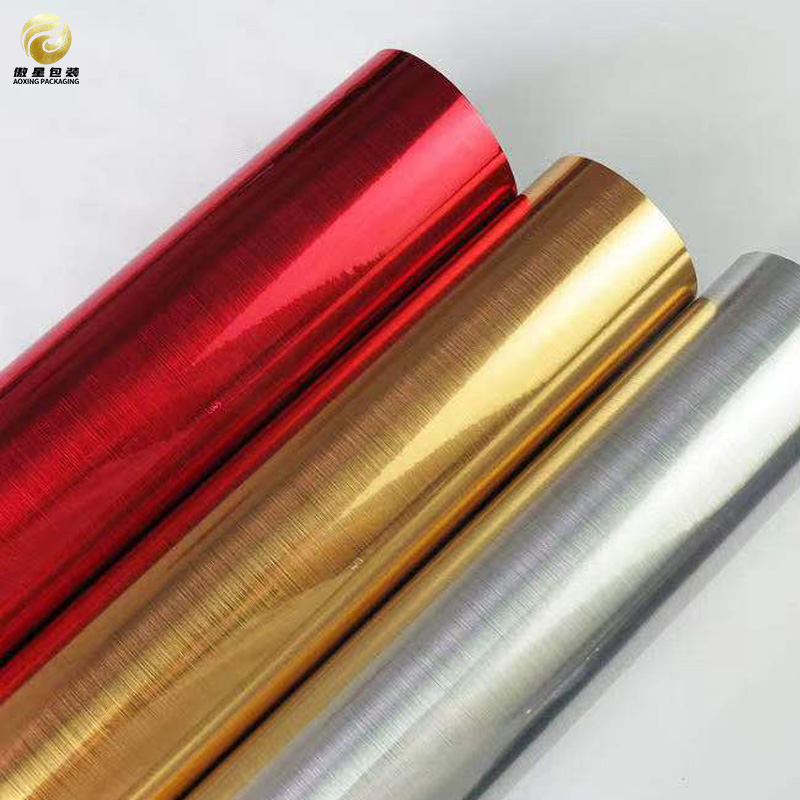

| Color Option | Red,Blue,Purple,Green,Gold,Yellow,Rose,Rainbow,etc. |

| Width & Length | Width:500~1800mm Length:Customized |

Detailed Descriptions

Product Description: Metallic Finish PET Film

Elevate your packaging and design projects with our premium Metallic Finish PET Film, a versatile and high-performance material engineered to meet the demands of modern applications. This exceptional film combines the durability of polyethylene terephthalate (PET) with a striking metallic finish, offering both aesthetic appeal and functional benefits.

Key Features:

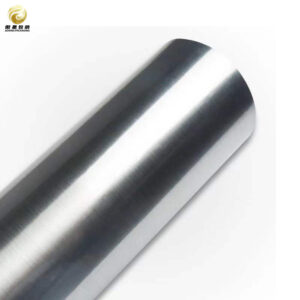

1. Stunning Aesthetic Appeal: The metallic finish of our PET film provides a luxurious and eye-catching appearance that enhances the visual impact of your products. Available in a variety of colors, including silver, gold, and holographic options, this film is perfect for creating standout packaging, labels, and promotional materials that capture attention.

2. Superior Durability: Crafted from high-quality PET, this film exhibits excellent resistance to tearing, puncturing, and environmental factors such as moisture and UV light. Its robust nature ensures that your products remain protected while maintaining their visual integrity over time.

3. Versatile Applications: Our Metallic Finish PET Film is suitable for a wide range of applications across various industries. Whether you are in the food and beverage sector looking to enhance product packaging or in the cosmetics industry aiming for an elegant presentation, this film adapts seamlessly to your needs. It is ideal for labels, wraps, pouches, and more.

4. Eco-Friendly Option: As sustainability becomes increasingly important in today’s market, our PET film stands out as an environmentally friendly choice. Made from recyclable materials, it aligns with eco-conscious practices without compromising on quality or performance.

5. Easy to Work With: The film’s excellent printability allows for high-quality graphics and designs to be applied effortlessly. It is compatible with various printing methods including flexographic, gravure, and digital printing, making it an ideal choice for businesses looking to customize their packaging solutions.

6. Temperature Resistance: Our Metallic Finish PET Film maintains its properties across a wide temperature range, making it suitable for both hot-fill applications and cold storage environments. This versatility ensures that your products remain safe and visually appealing regardless of storage conditions.

7. Customizable Options: We understand that every project is unique; therefore, we offer customizable sizes and thicknesses to meet your specific requirements. Our team is dedicated to providing tailored solutions that align with your vision.

Conclusion:

As a leading supplier and exporter of specialty films, we pride ourselves on being a reliable manufacturer that understands the unique requirements of our clients. Our Metallic Finish PET Film is ideal for applications ranging from packaging to decorative purposes, providing an eye-catching metallic sheen that enhances product visibility and consumer appeal.

We offer competitive bulk prices for businesses looking to bulk buy this exceptional film. Our wholesale options are tailored to accommodate both small and large orders, making it easy for you to stock up on this essential material without compromising on quality. As an OEM (Original Equipment Manufacturer), we also provide customization options to suit your specific needs, ensuring that you receive a product that aligns perfectly with your brand’s vision.

Whether you are a manufacturer seeking high-quality materials or a distributor looking for a dependable supplier, our Metallic Finish PET Film stands out as an excellent choice. With our commitment to excellence and customer satisfaction, we are dedicated to supporting your business with top-tier products and services.

Choose us as your trusted partner in sourcing Metallic Finish PET Film from China. Experience the difference that comes from working with a reputable producer who values quality, reliability, and innovation. Contact us today to learn more about our offerings and how we can assist you in achieving your business goals through effective material solutions.