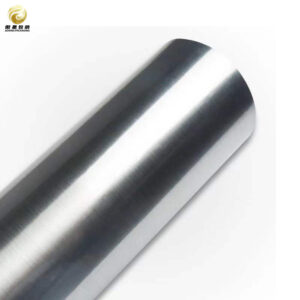

Gloss Coated PET

| Product | PET High Glossy Film |

| Material | PET + color+ aluminum layer / PET + aluminum + color layer |

| Thickness | 12~188um |

| Color Option | Red,Blue,Purple,Green,Gold,Yellow,Rose,Rainbow,etc. |

| Width & Length | Width:500~1800mm Length:Customized |

Detailed Descriptions

Gloss Coated PET, also known as Gloss Coated Polyethylene Terephthalate, is a type of packaging material that has been widely used in the packaging industry. It is a versatile and durable material that offers a high gloss finish, making it ideal for various applications. Gloss Coated PET is commonly used for food packaging, beverage packaging, pharmaceutical packaging, and personal care packaging.

The importance of Gloss Coated PET in the packaging industry cannot be overstated. With its enhanced appearance and improved durability, Gloss Coated PET not only protects the product inside but also attracts consumers with its visually appealing finish. Additionally, Gloss Coated PET offers increased barrier properties, ensuring that the contents remain fresh and protected from external factors such as moisture and oxygen. Moreover, Gloss Coated PET is cost-effective compared to other coating materials, making it a popular choice for manufacturers.

Understanding PET and its Properties

PET, or Polyethylene Terephthalate, is a thermoplastic polymer that is widely used in the packaging industry. It is known for its excellent mechanical properties, transparency, and chemical resistance. PET is lightweight yet strong, making it an ideal material for packaging applications.

The properties of PET contribute to its popularity in the packaging industry. Firstly, PET has excellent clarity and transparency, allowing consumers to see the product inside the package. This is especially important for food and beverage packaging where visual appeal plays a significant role in consumer decision-making. Secondly, PET has good barrier properties, protecting the contents from moisture, oxygen, and other external factors that could compromise the quality of the product. Additionally, PET is lightweight and shatter-resistant, reducing the risk of breakage during transportation and handling.

Benefits of Gloss Coated PET

1. Enhanced Appearance: One of the key benefits of Gloss Coated PET is its enhanced appearance. The high gloss finish gives the packaging a premium and luxurious look, making it stand out on the shelves. This is particularly important in industries such as cosmetics and personal care, where visual appeal plays a significant role in consumer purchasing decisions.

2. Improved Durability: Gloss Coated PET offers improved durability compared to other coating materials. It is resistant to scratches, tears, and punctures, ensuring that the packaging remains intact throughout the supply chain. This is crucial for products that require a longer shelf life or are prone to damage during transportation.

3. Increased Barrier Properties: Gloss Coated PET provides increased barrier properties, protecting the contents from moisture, oxygen, and other external factors. This helps to maintain the freshness and quality of the product, extending its shelf life. The barrier properties of Gloss Coated PET make it suitable for a wide range of products, including food, beverages, pharmaceuticals, and personal care items.

4. Cost-Effective: Gloss Coated PET is a cost-effective solution for packaging needs. It offers a high-quality finish at a lower cost compared to other coating materials such as glass or metal. Additionally, Gloss Coated PET is lightweight, reducing transportation costs and carbon footprint.

Applications of Gloss Coated PET

| Application | Metric |

|---|---|

| Labels and Stickers | High gloss finish for enhanced visual appeal |

| Packaging | Excellent barrier properties for extended shelf life |

| Printing | Sharp and vibrant colors for eye-catching designs |

| Decals and Signage | Durable and weather-resistant for outdoor use |

1. Food Packaging: Gloss Coated PET is widely used in food packaging due to its excellent barrier properties and visual appeal. It is commonly used for packaging snacks, confectionery, bakery products, and ready-to-eat meals. The high gloss finish enhances the presentation of the food products, making them more enticing to consumers.

2. Beverage Packaging: Gloss Coated PET is also extensively used in beverage packaging. It is commonly used for bottling water, carbonated drinks, juices, and alcoholic beverages. The high gloss finish gives the bottles a premium look and enhances the branding of the product.

3. Pharmaceutical Packaging: Gloss Coated PET is an ideal choice for pharmaceutical packaging due to its excellent barrier properties and chemical resistance. It is commonly used for packaging tablets, capsules, and liquid medications. The high gloss finish adds a professional touch to the packaging, instilling confidence in consumers.

4. Personal Care Packaging: Gloss Coated PET is widely used in the personal care industry for packaging products such as shampoos, conditioners, lotions, and cosmetics. The high gloss finish gives the packaging a luxurious look, attracting consumers and enhancing the brand image.

Manufacturing Process of Gloss Coated PET

1. Extrusion Coating: The manufacturing process of Gloss Coated PET involves extrusion coating. In this process, a layer of molten PET is extruded onto a substrate material, such as paper or cardboard. The molten PET is then cooled and solidified, forming a glossy coating on the substrate.

2. Lamination: Another manufacturing process for Gloss Coated PET is lamination. In this process, a layer of Gloss Coated PET film is laminated onto a substrate material using heat and pressure. The lamination process ensures that the Gloss Coated PET film adheres securely to the substrate, providing a glossy finish.

3. Co-Extrusion: Co-extrusion is another method used in the manufacturing of Gloss Coated PET. In this process, multiple layers of different materials are extruded simultaneously to form a composite structure. The outer layer is typically made of Gloss Coated PET, providing the glossy finish.

Factors Affecting the Quality of Gloss Coated PET

1. Raw Materials: The quality of Gloss Coated PET is highly dependent on the quality of the raw materials used in its production. High-quality PET resin and coating materials ensure that the final product has excellent clarity, gloss, and durability.

2. Coating Process: The coating process plays a crucial role in determining the quality of Gloss Coated PET. Factors such as temperature, pressure, and coating speed need to be carefully controlled to achieve the desired gloss and adhesion.

3. Storage Conditions: Proper storage conditions are essential to maintain the quality of Gloss Coated PET. It should be stored in a cool, dry place away from direct sunlight and moisture. Improper storage can lead to degradation of the coating, resulting in a loss of gloss and durability.

Comparison of Gloss Coated PET with Other Coatings

1. Gloss Coated PET vs. Gloss Coated Paper: Gloss Coated PET offers several advantages over gloss coated paper. Firstly, Gloss Coated PET has better barrier properties, providing superior protection to the contents. Secondly, Gloss Coated PET is more durable and resistant to tearing and punctures compared to paper. Lastly, Gloss Coated PET has a higher gloss finish, giving the packaging a more premium look.

2. Gloss Coated PET vs. Matte Coated PET: Gloss Coated PET and Matte Coated PET offer different visual effects. Gloss Coated PET has a high gloss finish, while Matte Coated PET has a matte or satin finish. The choice between the two depends on the desired aesthetic and branding strategy. Gloss Coated PET is often used for products that require a luxurious and premium look, while Matte Coated PET is preferred for a more understated and sophisticated appearance.

Sustainability of Gloss Coated PET

1. Recyclability of PET: PET is a highly recyclable material, making it an environmentally friendly choice for packaging. It can be recycled into new PET products or other plastic products such as polyester fibers for textiles.

2. Environmental Impact of PET: While PET is recyclable, its production does have an environmental impact. The production of PET requires energy and resources, and the disposal of non-recycled PET can contribute to waste accumulation. However, compared to other packaging materials such as glass or metal, PET has a lower carbon footprint and energy consumption.

Future of Gloss Coated PET in the Packaging Industry

1. Emerging Trends: The packaging industry is constantly evolving, and Gloss Coated PET is expected to continue to play a significant role in the future. Emerging trends such as sustainable packaging, personalized packaging, and smart packaging are likely to drive the demand for Gloss Coated PET.

2. Technological Advancements: Technological advancements in coating processes and materials are expected to further enhance the properties and performance of Gloss Coated PET. These advancements may include improved barrier properties, enhanced durability, and innovative finishes.

Tips for Handling and Storing Gloss Coated PET

1. Proper Handling Techniques: When handling Gloss Coated PET, it is important to avoid excessive pressure or rough handling that could damage the coating. It should be stored in a clean and dust-free environment to prevent scratches or contamination.

2. Storage Conditions: Gloss Coated PET should be stored in a cool, dry place away from direct sunlight and moisture. Exposure to extreme temperatures or humidity can affect the quality of the coating.

Is Gloss Coated PET the Right Choice for Your Packaging Needs?

In conclusion, Gloss Coated PET offers numerous benefits and applications in the packaging industry. Its enhanced appearance, improved durability, increased barrier properties, and cost-effectiveness make it a popular choice for various industries such as food, beverage, pharmaceuticals, and personal care. The manufacturing process of Gloss Coated PET involves extrusion coating, lamination, or co-extrusion. Factors such as raw materials, coating process, and storage conditions can affect the quality of Gloss Coated PET. When compared to other coatings such as gloss coated paper or matte coated PET, Gloss Coated PET offers superior properties and visual appeal. Additionally, Gloss Coated PET is recyclable and has a lower environmental impact compared to other packaging materials. With emerging trends and technological advancements in the packaging industry, Gloss Coated PET is expected to continue to be a preferred choice for packaging needs.

FAQs

What is Gloss Coated PET?

Gloss Coated PET is a type of plastic film that has been coated with a glossy finish. PET stands for polyethylene terephthalate, which is a type of thermoplastic polymer.

What are the properties of Gloss Coated PET?

Gloss Coated PET has a high gloss finish, is transparent, and has good barrier properties against moisture and gases. It is also resistant to chemicals and has good dimensional stability.

What are the applications of Gloss Coated PET?

Gloss Coated PET is commonly used in the packaging industry for products such as food, beverages, and pharmaceuticals. It is also used in the printing industry for labels, stickers, and other promotional materials.

What are the benefits of using Gloss Coated PET?

The benefits of using Gloss Coated PET include its high gloss finish, transparency, and good barrier properties. It also has good printability and is easy to process.

How is Gloss Coated PET produced?

Gloss Coated PET is produced by coating a layer of glossy material onto a PET film using a coating machine. The film is then dried and wound onto a roll for further processing.

Is Gloss Coated PET recyclable?

Yes, Gloss Coated PET is recyclable. However, it is important to check with local recycling facilities to ensure that they accept this type of plastic film.