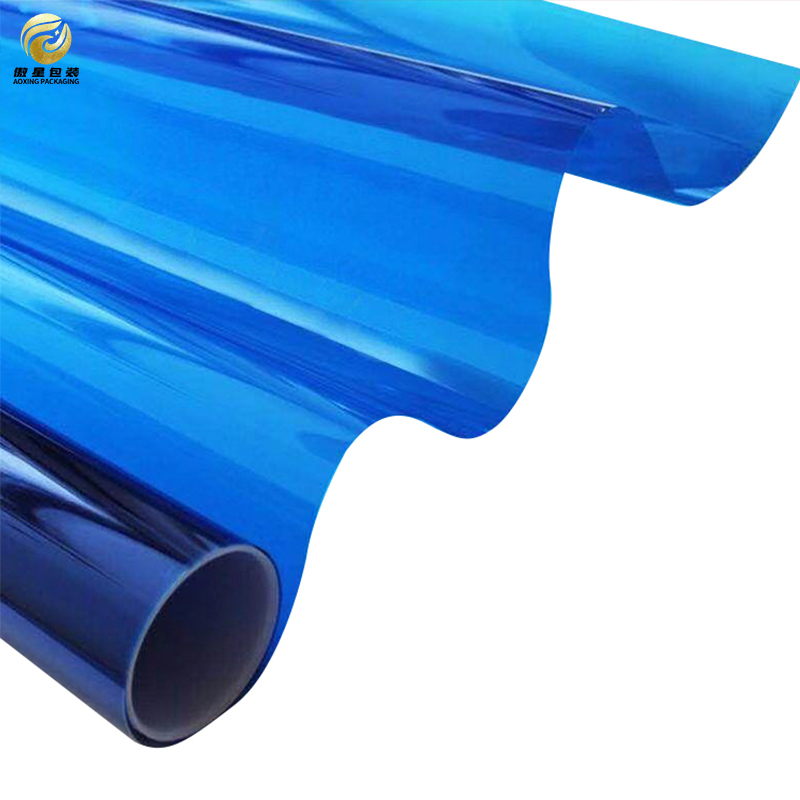

High Transparency OPP Film

| Product | Transparent OPP Film |

| Material | OPP+ color+ aluminum layer / OPP + aluminum + color layer |

| Thickness | 15um; 18um |

| Color Option | Red,Blue,Purple,Green,Gold,Yellow,Rose,Rainbow,etc. |

| Width & Length | Width:500~1800mm Length:Customized |

Detailed Descriptions

High Transparency OPP Film: Elevate Your Packaging Solutions

Introducing our High Transparency OPP (Oriented Polypropylene) Film, a premium packaging material designed to meet the diverse needs of modern industries. Engineered for excellence, this film combines superior clarity with exceptional durability, making it an ideal choice for a wide range of applications, from food packaging to retail displays.

Unmatched Clarity and Visual Appeal

Our High Transparency OPP Film is characterized by its crystal-clear finish, allowing products to be showcased in their best light. The high optical clarity ensures that colors remain vibrant and details are visible, enhancing the overall presentation of your packaged goods. Whether you are looking to package gourmet snacks, cosmetics, or promotional items, this film provides an attractive barrier that draws consumers’ attention while maintaining product integrity.

Exceptional Barrier Properties

In addition to its aesthetic advantages, our OPP Film offers outstanding barrier properties that protect your products from moisture, dust, and other environmental factors. This ensures that your items remain fresh and uncontaminated throughout their shelf life. The film’s resistance to punctures and tears further enhances its protective capabilities, making it a reliable choice for both short-term and long-term storage.

Versatile Applications

The versatility of High Transparency OPP Film makes it suitable for a variety of applications across multiple industries. It is commonly used in:

– Food Packaging: Ideal for wrapping snacks, baked goods, and perishable items while preserving freshness. – Retail Displays: Perfect for creating eye-catching packaging for retail products that require visibility without compromising on protection. – Stationery and Crafts: An excellent choice for wrapping gifts or creating custom packaging solutions in arts and crafts projects. – Industrial Uses: Suitable for packaging components or products that require visibility and protection during shipping and handling.

Eco-Friendly Options Available

In response to growing environmental concerns, we offer eco-friendly variants of our High Transparency OPP Film. These options are designed to minimize environmental impact while maintaining the same high-quality performance standards. By choosing our sustainable packaging solutions, you can align your business practices with eco-conscious values without sacrificing quality or functionality.

Easy Handling and Customization

Our High Transparency OPP Film is designed for ease of use in various manufacturing processes. It can be easily heat-sealed or laminated, allowing for seamless integration into existing production lines. Additionally, we offer customization options such as different thicknesses, widths, and lengths to meet specific project requirements.

Conclusion

As a reputable manufacturer with years of experience, we understand the importance of quality and consistency. Our factory adheres to stringent quality control measures throughout the production process, ensuring that every roll of OPP film meets our high standards. We offer competitive bulk prices for businesses looking to bulk buy, allowing you to optimize your purchasing strategy while maintaining quality.

In addition to our commitment to quality, we also offer OEM services tailored to your specific requirements. Whether you need custom sizes or unique branding options, our team is dedicated to providing solutions that align with your business goals. As a trusted wholesale supplier, we can accommodate orders of any size, ensuring that you receive the right amount of product at the right time.

Partnering with us means choosing a reliable exporter who understands the complexities of international trade. We are equipped to handle logistics efficiently, ensuring that your orders are delivered promptly and safely. Our extensive network allows us to serve clients across various regions, making us a preferred choice for businesses seeking high-quality packaging solutions.

In summary, our High Transparency OPP Film stands out as an exceptional product in the market. With our commitment to quality manufacturing in China and our status as a leading producer and supplier, we invite you to explore how our film can enhance your packaging needs. Contact us today for more information on bulk buying options and pricing details tailored specifically for your business requirements.