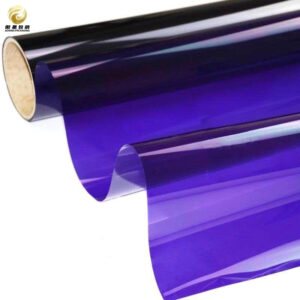

Clear Polypropylene Film

| Product | Transparent OPP Film |

| Material | OPP+ color+ aluminum layer / OPP + aluminum + color layer |

| Thickness | 15um; 18um |

| Color Option | Red,Blue,Purple,Green,Gold,Yellow,Rose,Rainbow,etc. |

| Width & Length | Width:500~1800mm Length:Customized |

Detailed Descriptions

Product Description: Clear Polypropylene Film

Introducing our premium Clear Polypropylene Film, a versatile and high-performance material designed to meet the diverse needs of various industries. Engineered for excellence, this film combines clarity, strength, and flexibility, making it an ideal choice for packaging, labeling, and protective applications.

Key Features:

1. Exceptional Clarity: Our Clear Polypropylene Film boasts outstanding optical clarity, ensuring that your products are showcased in the best possible light. This transparency enhances visibility and allows for vibrant colors and intricate designs to shine through, making it perfect for retail packaging and promotional materials.

2. Durability and Strength: Crafted from high-quality polypropylene resin, this film exhibits remarkable tensile strength and resistance to tearing. Its robust nature ensures that it can withstand the rigors of handling and transportation while providing reliable protection for your products.

3. Chemical Resistance: The Clear Polypropylene Film is inherently resistant to a wide range of chemicals, oils, and greases. This feature makes it suitable for applications in food packaging, industrial uses, and environments where exposure to harsh substances is a concern.

4. Lightweight and Flexible: Despite its strength, this film remains lightweight and flexible, allowing for easy manipulation during production processes. Its adaptability makes it an excellent choice for a variety of applications, from wrapping delicate items to creating custom-sized bags.

5. Eco-Friendly Options: We are committed to sustainability; therefore, our Clear Polypropylene Film is available in recyclable options. This aligns with environmentally conscious practices while maintaining the quality and performance you expect from our products.

6. Customizable Solutions: Understanding that every project has unique requirements, we offer customizable options in terms of thickness, width, and finish. Whether you need a thin film for lightweight applications or a thicker variant for added protection, we can tailor our product to meet your specifications.

Applications:

– Packaging: Ideal for food packaging, retail products, and gift wrapping. – Labels: Perfect for creating clear labels that adhere well to various surfaces. – Protective Covers: Used as protective sheeting in construction or manufacturing environments. – Stationery Products: Suitable for folders, binders, and other office supplies requiring transparency.

Conclusion:

As a reputable manufacturer with years of experience in the industry, we understand the importance of quality and reliability. Our Clear Polypropylene Film is produced using advanced technology and stringent quality control measures, ensuring that every roll meets the highest standards. Whether you are looking for a reliable material for food packaging, stationery products, or industrial applications, our film offers the perfect balance of flexibility and strength.

We cater to businesses of all sizes and offer competitive bulk prices for those looking to bulk buy our Clear Polypropylene Film. Our wholesale options are designed to provide cost-effective solutions without compromising on quality. As an established exporter, we have successfully supplied our products to clients around the globe, ensuring timely delivery and exceptional service.

For businesses seeking customized solutions, we also offer OEM services tailored to your specific requirements. Our team is dedicated to working closely with you to develop bespoke products that align with your brand’s vision and operational needs.

Choose us as your trusted partner in sourcing Clear Polypropylene Film. With our commitment to excellence as a factory-direct supplier, you can be confident in receiving top-notch products at competitive prices. Contact us today to learn more about our offerings and how we can support your business needs with our high-quality polypropylene film solutions.