What Are Metalized Polyester Films and What Unique Properties Do They Offer?

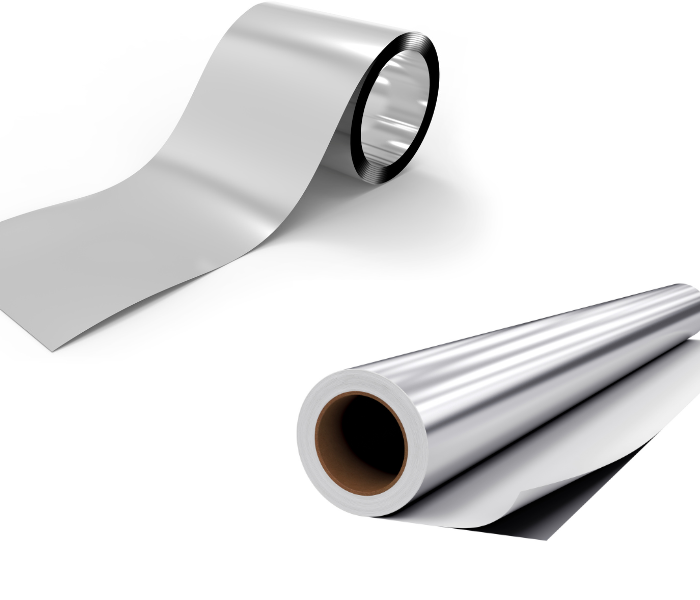

Metalized polyester films are polyester sheets coated with a very thin layer of metal. This layer usually consists of aluminum, tin, or chromium, giving the films a mirror-like, reflective finish. These films are also known as metallized PET films when polyester specifically refers to polyethylene terephthalate (PET), one of the most common polyester types used. The metal coating changes the film's properties, making them special for many uses across industries, especially in packaging, electronics, and insulation.

How Are Metalized Polyester Films Made?

Metalized polyester films start as a base polyester film, often biaxially oriented PET (BOPET), known for strength and clarity. The metal layer is applied through a process called vacuum metallization. In this method, the film travels inside a vacuum chamber, where metal strips are heated until they evaporate. The metal vapor then condenses and forms an ultra-thin coating on the film’s surface. This coating is so thin—usually only 40 to 100 nanometers thick—it adds reflectivity and barrier properties without making the film heavy or stiff.

Vacuum metallization ensures an even and uniform metal coat. This process is different from other coating methods because it limits metal usage, improves surface smoothness, and keeps the film flexible.

Metals Used for Metallization and Their Effects

The choice of metal affects the film’s properties:

- Aluminum (Al): The most common metal used. It offers excellent reflectivity, electrical conductivity, and barrier protection against oxygen and moisture.

- Tin (Sn): Used less often, tin adds chemical stability and corrosion resistance.

- Chromium (Cr): Provides a hard, corrosion-resistant surface with good reflectivity. Chromium coatings are useful when durability is crucial.

Each metal serves specific industrial purposes but aluminum is the favorite due to cost-effectiveness and strong performance.

What Physical Properties Set Metalized Polyester Films Apart?

Metalized polyester films have several key physical attributes that make them stand out:

| Property | Description |

|---|---|

| Reflectivity | Shiny, mirror-like surface that reflects visible and UV light efficiently. |

| Tensile Strength | High strength and tear resistance from the base polyester film. |

| Thermal Stability | Can withstand high temperatures without losing shape or function. |

| Dimensional Stability | Maintains size and shape under stress and temperature changes. |

| Flexibility | Unlike metal foils, these films bend and fold without cracking. |

These characteristics make metalized polyester films suitable for applications where both strength and a reflective, attractive surface are needed.

Superior Barrier Properties Against Moisture, Oxygen, and UV Light

One of the greatest advantages is their barrier properties. The metal coating acts as a shield against:

- Moisture: Drastically lowers water vapor transmission rates, protecting contents from humidity.

- Oxygen: Reduces oxygen permeability by up to 100 times compared to bare films.

- UV Light: Blocks ultraviolet radiation, preventing product degradation caused by sunlight.

This triple shield keeps packaged food, pharmaceuticals, and chemicals fresh longer and maintains product integrity. The thin metal layer makes these films light yet highly protective compared to aluminum foil alternatives.

Optical Characteristics: Gloss, Transparency, and Texture Variations

Metalized polyester films come in various finishes and optical qualities:

- Glossy Finish: High shine and smoothness, ideal for premium packaging and decorative uses.

- Matte Finish: Created by coating with microfine silica particles, offering low glare but some light scattering.

- Silky Texture: A softer sheen with moderate reflectiveness, used where a subtle metal look is desired.

- Transparency: Usually low as metal coating blocks light, but films can be partially metallized to balance transparency and reflectivity.

These optics enhance product appeal on shelves and in visual displays.

Chemical Resistance and Durability Features

The metalized coating and polyester film base combine to provide:

- Abrasion Resistance: Surface resists scratches and wear during handling and transport.

- Corrosion Resistance: Aluminum and chromium layers prevent rust and degradation.

- Chemical Resistance: Strong against oils, solvents, and common chemicals encountered in packaging or industrial use.

- Durability Under Stress: Withstands bending, folding, and temperature cycling without loss of function.

These features allow metalized polyester films to protect contents and maintain appearance during rough conditions.

What Makes Metalized Polyester Films Unique Compared to Other Packaging Materials?

Compared with other materials like aluminum foil, plastic laminates, or paper, metalized polyester films offer:

- Lightweight and Flexible: Easier to handle and less bulky than foil.

- High Tensile Strength: Resists tearing better than foil.

- Superior Barrier with Lower Thickness: Thinner films can provide equal or better moisture and oxygen barriers.

- Enhanced Aesthetics: Mirror-like or textured surfaces enrich product packaging and branding.

- Better Thermal Stability: Handles heating, freezing, and microwave use safely.

- Electrical Conductivity: Useful in electronics for EMI shielding or flexible circuits.

How Does Metallization Affect Film Properties Like Barrier and Reflectivity?

The thin metal layer fundamentally changes film performance:

- Barrier Improvement: Creates a nearly impermeable shield to gases and moisture.

- Reflectivity Boost: Metal surface reflects light, UV rays, and heat effectively.

- Enhanced Electrical Properties: Adds conductivity not seen in base polymer films.

- Aesthetic Upgrade: Transforms simple plastic film into a high-end metallic finish.

This combination boosts overall film performance, extending shelf life and broadening industrial uses.

Exploring the unique properties of metalized polyester films reveals a versatile, high-performance material. Its blend of physical strength, genetic barrier defenses, reflective beauty, and chemical durability sets it apart. Whether in food packaging, electronics, automotive parts, or decorative laminates, metalized polyester films offer unmatched advantages.

How Are Metalized Polyester Films Used Across Industries and What Benefits Do They Provide?

Metalized polyester films are used in many industries. Their unique mix of light blockage, gas barrier, and reflectivity makes them key in packaging, electronics, automotive, and more. Let’s explore the main uses and benefits they bring to these fields.

Main Industrial Applications of Metalized Polyester Films

Metalized polyester films are thin plastic sheets coated with metals like aluminum. This coating adds a shiny, reflective surface and blocks moisture, oxygen, and UV light. Here are key industrial applications:

- Flexible packaging: For food, beverages, and pharmaceuticals.

- Electronics: EMI shielding, flexible circuits, and insulation.

- Automotive and aerospace: Heat shields and lightweight insulation.

- Construction and HVAC: Thermal insulation and vapor barriers.

- Agriculture: Greenhouse films and reflective mulching.

- Graphics and branding: Labels, displays, and decorative laminates.

The combination of barrier protection, electrical properties, and eye-catching shine makes metalized films versatile.

Metalized Polyester Films in Packaging for Food, Beverages, and Pharmaceuticals

Packaging is one of the largest uses of metalized polyester films. Their barrier properties help keep products fresh and safe.

- Moisture and oxygen barrier: These films reduce water vapor and oxygen passing by up to 100 times compared with regular plastic. That keeps food crisp and free from spoilage.

- Light protection: Their reflective metal layer blocks UV rays that degrade vitamins, colors, and flavors.

- Odor and aroma retention: They help keep the original scent and taste of products like coffee, spices, and powdered drinks.

- Durability: The film resists tears and punctures, protecting contents during shipping.

- Formats and finishes: Available as peelable lids, glossy or matte films for rigid or flexible packaging.

Common uses include snack bags, cocoa powder pouches, seasoning packs, and blister packs for medicines. These films also meet food safety standards without heavy metals.

Benefits in Automotive, Aerospace, and Renewable Energy Sectors

Metalized polyester films serve important roles in industries where weight, heat, and durability matter.

- Automotive uses: They act as reflective heat shields under hoods and inside cabins. This lowers engine heat transfer and improves passenger comfort. Their lightweight nature helps meet fuel efficiency targets.

- Aerospace: Metalized films form part of thermal blankets for spacecraft and aircraft insulation. They reflect radiant heat, aging slower than heavy foil insulations.

- Renewable energy: Solar panels use these films to reflect sunlight onto cells efficiently, boosting power output while protecting components from moisture and UV damage.

These films stand out for thermal stability, tensile strength, and corrosion resistance. Unlike foil, metalized polyester is flexible, lighter, and less fragile.

Enhancing Electronics Performance: EMI Shielding and Flexible Circuits

Electronics demand materials that block electromagnetic interference (EMI) and allow complex signal paths. Metalized polyester films fit this well.

- EMI shielding: Their metal layer blocks stray radio or electrical signals, protecting components. This is crucial in devices sensitive to noise.

- Flexible printed circuits: The films serve as substrates for circuits that bend and flex without damage. Their thermal and electrical stability ensures long life.

- Capacitors and insulation: Metalized films are used inside capacitors for high-voltage insulation and energy efficiency.

As demand for smaller, lighter electronics grows, metalized polyester films offer a valuable mix of electrical shielding, strength, and thin profile.

Role in Construction, Insulation, and HVAC Systems

Metalized polyester films help control heat, moisture, and air flow in buildings and HVAC systems.

- Thermal insulation: The reflective surface reduces radiant heat loss or gain, improving energy efficiency.

- Moisture barrier: They stop water vapor infiltration, preventing mold and degradation in walls and roofs.

- HVAC ducts and filters: Films provide barrier properties and durability in ductwork insulation and protective layers.

- Vapor retarders: In cold climate construction, these films help maintain indoor air quality by controlling moisture migration.

Compared to aluminum foil, metalized polyester films resist wrinkling and corrosion. Their flexibility also simplifies installation.

Enhancing Aesthetics and Branding: Labels, Displays, and Decorative Laminates

The shiny finish of metalized polyester films makes them popular for product presentation.

- Labels and stickers: Reflective eye-catching designs draw consumer attention.

- Point-of-sale displays and posters: Films enhance gloss and contrast.

- Decorative laminates: Automotive interiors, appliance panels, and consumer goods use metalized films for a sleek look without heavy weight or cost.

The films come in multiple finishes—bright, silky, matte—and can be textured for unique effects. This turns ordinary products into premium ones.

Agriculture Uses: Greenhouse Insulation and Reflective Mulching

Agriculture benefits from metalized films mainly by helping control temperatures and light levels.

- Greenhouse films: Their reflectivity improves light distribution inside greenhouses.

- Reflective mulching: Films laid on soil reflect sunlight onto plants to boost photosynthesis, reduce weeds, and control soil temperature.

- Durability: The films resist sunlight damage and moisture from irrigation.

These features increase crop yield and quality. Lightweight and flexible metalized films are easier to install and remove than thicker materials.

Advantages Over Foil and Other Barrier Materials

| Feature | Metalized Polyester Film | Aluminum Foil |

|---|---|---|

| Weight | Much lighter | Heavier |

| Flexibility | High, resists cracking or wrinkling | Stiff, prone to creasing |

| Tear Resistance | Superior | Lower |

| Corrosion Resistance | High | Prone to corrosion |

| Barrier Properties | Excellent moisture and oxygen barrier, but slightly less than foil | Excellent barrier, especially for gases |

| Thermal Stability | High | Variable |

| Electrical Conductivity | Good | Excellent |

| Aesthetic Appeal | Metal-like sheen with texture options | Metallic only |

| Cost | Cost-effective | Often more expensive |

| Recyclability | Recyclable with special processing | Easily recyclable |

Metalized polyester films are often preferred where durability, flexibility, and decorative finish matter. They lower shipping costs thanks to light weight and reduce waste with high strength.

By exploring these applications and benefits, you see why metalized polyester films have become essential across many industries. They raise product quality, extend shelf life, boost energy efficiency, and improve product appeal—all while offering a premium, versatile, and cost-effective solution.

What Factors Influence the Selection, Sustainability, and Performance of Metalized Polyester Films?

When you explore the unique properties of metalized polyester films, understanding how to select the right film is essential. Many aspects affect their choice, performance, and sustainability, especially for applications like packaging, insulation, and electronics.

Key Factors in Metalized Polyester Film Selection

Selecting the right metalized polyester film depends on several important factors:

- Product Sensitivity: If the product inside is sensitive to light, moisture, or oxygen, you need a film with a strong barrier to protect it.

- Storage Conditions: Films stored in humid or hot environments require higher barrier and thermal stability to avoid degradation.

- Intended Use: Packaging for food might require different properties than insulation or label applications.

- Compatibility: The film must work smoothly with your production equipment (e.g., sealing machines).

- Appearance Needs: Sometimes a glossy or matte finish is preferred for aesthetics or branding.

How Product Sensitivity and Storage Environment Affect Film Choice

The sensitivity of your product to environmental factors guides the film choice:

- Light Sensitive Products: Products like pharmaceuticals and perishables need films with low light transmittance; metalized polyester films offer excellent light barrier due to their reflective metal layer.

- Moisture and Oxygen Sensitive Items: Items such as coffee or powdered drinks require films with exceptional moisture and oxygen barriers. Metalized polyester films reduce oxygen and water vapor permeation by up to 100 times.

- Storage Temperature: For hot or cold storage, films with high thermal stability and dimensional stability are necessary. Metallized PET films perform well in temperatures from -60°C up to +150°C.

- Humidity: High humidity can cause packaging failure, so selecting films resistant to moisture is critical for certain climates or storage conditions.

Technical Standards and Metal Layer Thickness Impact Film Performance

| Property | Typical Metal Layer Thickness (nm) | Effect |

|---|---|---|

| Barrier Properties (moisture/oxygen) | 40-100 nm | Thicker layers boost barrier but reduce transparency |

| Reflectivity | 50-80 nm | Sufficient layer for mirror-like shine and UV protection |

| Thermal Stability | Depends on polymer & metal mix | Ensures durability at elevated temps |

| Electrical Conductivity | Thin layers (30-70 nm) | Important for EMI shielding and flexible circuits |

Vacuum metallization deposits a uniform metal layer, usually aluminum, on the polyester base. Thicker layers improve barrier properties but can increase cost and reduce flexibility. Balancing these specs is key.

Comparison: Metalized Polyester Films vs. BOPP and PA Films

| Feature | Metallized PET Films | Metallized BOPP Films | Metallized PA Films |

|---|---|---|---|

| Tensile Strength | High (strong & durable) | Moderate | High |

| Barrier to Moisture/Oxygen | Very high barrier | Moderate | Very high oxygen barrier |

| Thermal Stability | Excellent (up to +150°C) | Moderate | Good |

| Transparency | Generally opaque; can be textured | Higher gloss & transparency | Less transparent |

| Flexibility | Good | Excellent | Moderate |

| Cost | Mid to premium range | Low cost | Higher cost |

| Applications | Flexible packaging, insulation, electronics | Food packaging | Vacuum packaging |

Metalized PET films offer superior tensile strength and thermal resistance, ideal for demanding uses like electronics and insulation. BOPP films excel in moisture resistance at lower costs, favored in snack packaging. PA films focus on oxygen barrier and puncture resistance, good for vacuum packaging.

Environmental Challenges and Recyclability Options for Metalized Polyester Films

Metalized polyester films pose specific environmental concerns:

- Recycling Difficulty: The thin metal layer bonded to polyester complicates recycling. It requires specialized processes to separate metal from polymer.

- Waste Management: Improper disposal can contribute to microplastic pollution since PET is synthetic.

- Limited Collection Systems: Few facilities have the technology to recycle metallized films compared to pure plastics or aluminum.

Despite these challenges, metallized PET films are recyclable under advanced facilities. Mechanical recycling involves separating films from other waste and heat processing, while chemical recycling can recover raw materials more fully.

Sustainability and Eco-Friendliness of Metalized Polyester Films

Compared to traditional packaging materials like aluminum foil or multilayer laminates, metalized polyester films have sustainability advantages:

- Lightweight: They are lighter than metal foils, decreasing transportation energy.

- Material Efficiency: Uses less raw metal than foil, reducing resource use.

- Extended Product Shelf Life: Superior barrier functions help reduce food waste.

- Free of Heavy Metals: Safe for food packaging without toxic element concerns.

- Recyclability Potential: When recycled correctly, they reduce landfill.

On the other hand, the difficulty of recycling metallized films means many still end up in landfills or incinerators, highlighting a need for better recycling infrastructure and film design for sustainability.

Emerging Innovations to Enhance Recyclability and Environmental Impact

Recent innovations aim to solve sustainability challenges:

- Mono-Material Films: Development of metalized films with a single polymer layer to simplify recycling.

- Bio-based Polyester Films: Research into bio-sourced PET reduces carbon footprint.

- Improved Coating Techniques: Thinner or alternative metal coatings that maintain barrier but ease recycling.

- Chemical Recycling Advances: New processes to chemically reclaim both the metal and polymer from metallized films.

- Recyclable Laminates: Designing films that peel apart easily for separate recycling streams.

- Circular Economy Initiatives: Brands and manufacturers adopting take-back and recycling programs specifically for metallized films.

How to Choose the Right Metalized Polyester Film for Packaging or Insulation

When choosing metalized polyester films, match these to your needs:

- Barrier Level Needed: For highly sensitive products, opt for films with thicker metal layers.

- Mechanical Stress: If durable and tear-resistant packaging is critical, select PET over BOPP or PA.

- Thermal Conditions: Harsh environments require high thermal stability of PET.

- Aesthetic Requirements: Choose glossiness or matte finish based on branding.

- Recyclability Goals: Consider if a specific recyclable mono-material film is available.

- Budget Constraints: Balance cost with required properties; BOPP is cheaper but less durable.

Are Metalized Polyester Films Recyclable and Eco-Friendly?

Yes, but with qualifications:

- Recyclable under specialty programs but not widespread curbside.

- More eco-friendly than aluminum foil due to weight and materials saved.

- Industry moving towards better recycling technologies and sustainable alternatives.

- Using metallized PET films helps reduce food waste, which indirectly benefits the environment.

Performance Trade-Offs When Using Metallized Polyester Films vs. Other Materials

-

Pros of Metallized PET:

- Strong mechanical and thermal properties.

- Great barrier protection.

- Flexible and lightweight.

- Aesthetically premium.

-

Cons:

- More expensive than BOPP.

- Slightly less gas-tight than aluminum foil.

- Recycling complexity.

-

Choosing other materials: BOPP offers cheaper moisture barrier; PA is superior for oxygen-sensitive packed goods; aluminum foil has best gas barrier but is heavier and fragile.

By carefully considering these factors, you can make the best choice for metalized polyester films customized to your product needs, environmental goals, and performance demands. This knowledge lets you fully explore the unique properties of metalized polyester films.

FAQs about Explore the unique properties of metalized polyester films.

What are metalized polyester films and what unique properties do they offer?

Metalized polyester films are polyester sheets coated with a thin metal layer, typically aluminum, tin, or chromium, providing a mirror-like reflective finish with exceptional barrier, tensile strength, thermal stability, dimensional stability, and flexibility. These properties make them ideal for packaging, electronics, insulation, and decorative applications.

How are metalized polyester films made?

Metalized polyester films are made by vacuum metallization, where a thin metal layer (40 to 100 nanometers thick) is deposited on a polyester film inside a vacuum chamber, resulting in a uniform, flexible, and reflective coating that enhances barrier and surface properties.

What benefits do metalized polyester films provide in packaging and other industries?

Metalized polyester films provide excellent moisture, oxygen, and UV light barriers, electrical conductivity, high tensile strength, thermal stability, and attractive aesthetics, enabling them to preserve food and pharmaceuticals, shield electronics, improve thermal insulation, and enhance product branding.

How does the choice of metal affect the performance of metalized polyester films?

The choice of metal—aluminum for reflectivity and barrier, tin for chemical stability, or chromium for hardness and corrosion resistance—impacts the film’s durability, electrical properties, and protective performance in various industrial applications.

What key factors influence the selection and performance of metalized polyester films?

Selection depends on product sensitivity to

Metalized polyester films stand out for their unique barrier and reflective properties. I covered their production, key metals used, and how vacuum metallization enhances their traits. We explored wide applications—from food packaging to electronics and construction—and detailed benefits like durability and UV resistance. Finally, I discussed how to pick the right film based on use and sustainability concerns. These films offer a smart blend of strength, protection, and versatility, making them a top choice across many industries today.