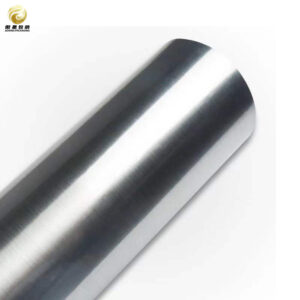

Rollo de poliéster transparente

| Producto | Film PET transparente |

| Material | PET + color+ capa de aluminio / PET + aluminio + capa de color |

| Espesor | 12~188um |

| Opción de color | Rojo, azul, púrpura, verde, oro, amarillo, rosa, arco iris, etc. |

| Anchura y longitud | Anchura:500~1800mm Longitud:Personalizada |

Descripciones detalladas

Product Description: Transparent Polyester Roll

Elevate your packaging and crafting projects with our premium Transparent Polyester Roll, a versatile and high-performance material designed to meet the diverse needs of both professionals and hobbyists. Crafted from high-quality polyester, this roll offers exceptional clarity and durability, making it an ideal choice for a wide range of applications.

Key Features:

1. Exceptional Clarity: Our Transparent Polyester Roll boasts a crystal-clear finish that enhances visibility, allowing you to showcase your products or designs without obstruction. This transparency is perfect for applications where aesthetics are paramount, such as packaging for retail items, displays, or artistic projects.

2. Durable Construction: Made from robust polyester material, this roll is engineered to withstand wear and tear while maintaining its structural integrity. Its resistance to tearing and puncturing ensures that your projects remain intact, providing peace of mind during handling and transportation.

3. Versatile Applications: The Transparent Polyester Roll is suitable for a myriad of uses, including but not limited to: – Packaging: Ideal for wrapping gifts, food items, or retail products that require visibility. – Crafting: Perfect for scrapbooking, card making, or other creative endeavors where transparency adds value. – Industrial Uses: Suitable for labeling, protective covers, or as a component in manufacturing processes.

4. Easy to Work With: This roll is designed for convenience. It can be easily cut to size with standard cutting tools, allowing you to customize it according to your specific requirements. Its lightweight nature makes it easy to handle and apply in various settings.

5. Eco-Friendly Option: Our Transparent Polyester Roll is produced with sustainability in mind. It is recyclable and can be disposed of responsibly, making it an excellent choice for environmentally-conscious consumers looking to minimize their ecological footprint.

6. Available in Various Sizes: To accommodate different project needs, our Transparent Polyester Roll comes in multiple widths and lengths. Whether you require a small roll for personal use or a larger quantity for commercial applications, we have the right option for you.

As a leading supplier and exporter of transparent polyester products, we pride ourselves on being a reliable manufacturer that understands the unique requirements of our clients. Our transparent polyester rolls are ideal for applications ranging from packaging and labeling to crafting and industrial uses. The exceptional transparency and strength of our polyester make it an excellent choice for businesses looking to enhance their product presentation while ensuring protection.

We offer competitive bulk prices for those looking to bulk buy, allowing you to maximize your savings without compromising on quality. Our wholesale options cater to businesses of all sizes, providing flexibility for both small-scale operations and large enterprises. As an OEM (Original Equipment Manufacturer), we also provide customized solutions tailored to your specific needs, ensuring that you receive a product that aligns perfectly with your project requirements.

Whether you are a retailer seeking a dependable supplier or a manufacturer in need of high-quality materials, our Transparent Polyester Roll is the ideal choice. With our commitment to excellence and customer satisfaction, we stand ready to support your business with top-notch products and services. Choose us as your trusted partner in sourcing transparent polyester rolls that deliver both performance and value.