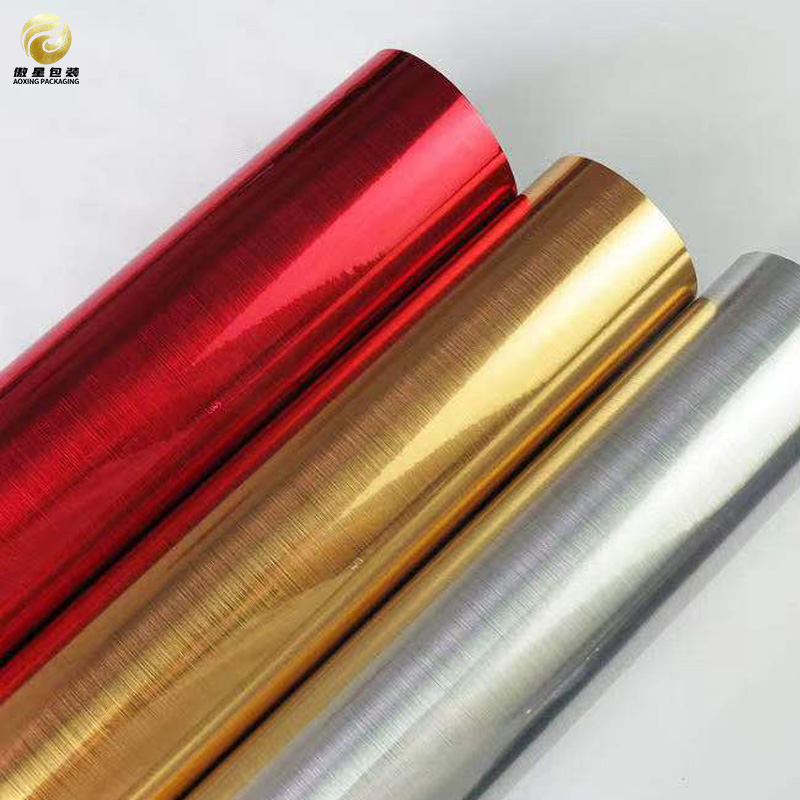

Film de poliéster cepillado

| Producto | Película PET cepillada |

| Material | PET + color+ capa de aluminio / PET + aluminio + capa de color |

| Espesor | 12~188um |

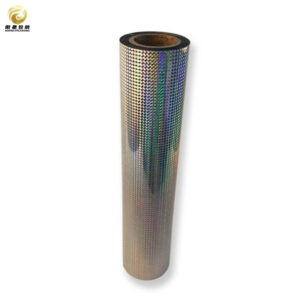

| Opción de color | Rojo, azul, púrpura, verde, oro, amarillo, rosa, arco iris, etc. |

| Anchura y longitud | Anchura:500~1800mm Longitud:Personalizada |

Descripciones detalladas

Product Description: Brushed Polyester Film

Introducing our premium Brushed Polyester Film, a versatile and high-performance material designed to meet the demanding needs of various industries. Engineered with precision, this film combines aesthetic appeal with exceptional functionality, making it an ideal choice for applications ranging from packaging to decorative surfaces.

Key Features:

1. Superior Durability: Our Brushed Polyester Film is crafted from high-quality polyester, ensuring outstanding resistance to wear and tear. Its robust nature makes it suitable for both indoor and outdoor applications, providing long-lasting performance even in challenging environments.

2. Elegant Aesthetic: The brushed finish of the film offers a sophisticated texture that enhances visual appeal. This unique surface treatment not only adds a touch of elegance but also helps to minimize glare, making it an excellent choice for display and signage applications.

3. Excellent Printability: Designed for optimal ink adhesion, our Brushed Polyester Film is compatible with a wide range of printing techniques, including digital, screen, and UV printing. This feature allows for vibrant colors and sharp images, ensuring that your designs stand out.

4. Chemical Resistance: The film exhibits remarkable resistance to chemicals and solvents, making it suitable for use in environments where exposure to harsh substances is a concern. This property ensures that the integrity of the film remains intact over time.

5. Lightweight and Flexible: Despite its durability, our Brushed Polyester Film is lightweight and flexible, allowing for easy handling and application. This characteristic makes it ideal for use in various projects where adaptability is essential.

6. Eco-Friendly Options: We are committed to sustainability; therefore, our Brushed Polyester Film is available in eco-friendly variants that meet environmental standards without compromising on quality or performance.

Applications:

– Packaging Solutions: Ideal for creating attractive packaging that protects products while enhancing brand visibility. – Decorative Elements: Perfect for interior design projects, including wall coverings and furniture finishes that require a touch of sophistication. – Signage and Displays: Suitable for both indoor and outdoor signage where durability and aesthetics are paramount. – Automotive Uses: Can be utilized in automotive interiors or exteriors where a brushed finish is desired without sacrificing strength.

Conclusion:

Brushed Polyester Film is renowned for its unique texture and aesthetic appeal, making it an ideal choice for applications ranging from packaging to decorative surfaces. The film’s brushed finish not only enhances its visual characteristics but also provides superior durability and resistance to wear, ensuring that your products maintain their integrity over time.

As a prominent exporter of Brushed Polyester Film, we offer competitive bulk prices that cater to businesses looking to bulk buy for their production needs. Our wholesale options are designed to provide flexibility and cost-effectiveness, allowing you to optimize your supply chain without compromising on quality. Whether you are a small business or a large corporation, our tailored solutions can accommodate your specific requirements.

We also specialize in OEM services, enabling you to customize the film according to your brand specifications. Our experienced team works closely with clients to ensure that every aspect of the product meets their expectations, from material selection to final delivery.

By choosing us as your partner for Brushed Polyester Film, you are not only investing in a high-quality product but also aligning with a reputable supplier dedicated to supporting your business growth. With our extensive experience in the industry and commitment to customer satisfaction, we are confident that we can meet your needs effectively.

Explore the possibilities with our Brushed Polyester Film today and discover why we are recognized as a leading manufacturer in the market. Contact us for more information on bulk purchasing options or to discuss how we can assist you with your specific project requirements.