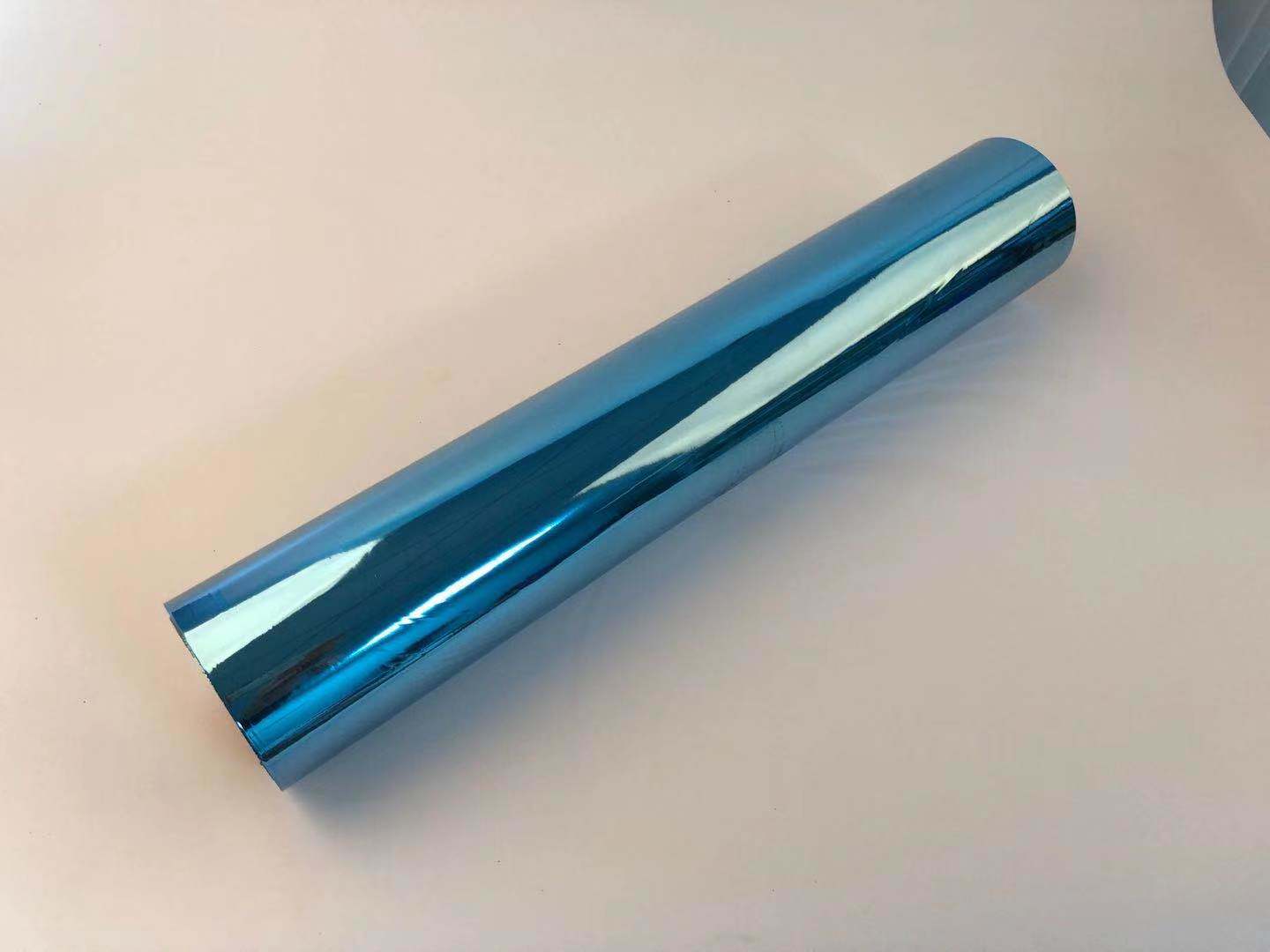

OPP metalizado de barrera

| Producto | Película OPP metalizada |

| Material | OPP + color+ capa de aluminio / OPP + aluminio + capa de color |

| Espesor | 15um;18um |

| Opción de color | Rojo, azul, púrpura, verde, oro, amarillo, rosa, arco iris, etc. |

| Anchura y longitud | Anchura:500~1800mm Longitud:Personalizada |

Descripciones detalladas

Product Description: Barrier Metallized OPP Film

Introducing our premium Barrier Metallized OPP (Oriented Polypropylene) film, a cutting-edge packaging solution designed to meet the rigorous demands of modern industries. This high-performance film combines the exceptional properties of oriented polypropylene with a sophisticated metallized layer, offering unparalleled protection and aesthetic appeal for a wide range of applications.

Key Features:

1. Superior Barrier Properties: Our Barrier Metallized OPP film is engineered to provide an outstanding barrier against moisture, oxygen, and light. This ensures that your products remain fresh and retain their quality for extended periods, making it an ideal choice for food packaging, pharmaceuticals, and other sensitive materials.

2. Enhanced Aesthetic Appeal: The metallized surface not only enhances the visual appeal of your packaging but also adds a touch of sophistication. The reflective quality of the film creates an eye-catching finish that can elevate your brand’s presence on retail shelves.

3. Lightweight and Durable: Despite its lightweight nature, our metallized OPP film boasts exceptional strength and durability. It is resistant to tearing and puncturing, ensuring that your products are well-protected during transportation and storage.

4. Versatile Applications: This versatile film is suitable for a variety of applications, including snack packaging, confectionery wrappers, cosmetic containers, and more. Its compatibility with various printing techniques allows for vibrant graphics and branding opportunities.

5. Eco-Friendly Options: We understand the importance of sustainability in today’s market. Our Barrier Metallized OPP film is available in eco-friendly options that meet industry standards for recyclability and reduced environmental impact.

6. Customizable Solutions: We offer tailored solutions to meet your specific packaging needs. Whether you require custom sizes, thicknesses, or finishes, our team of experts is ready to collaborate with you to create the perfect solution for your product.

Applications:

– Food Packaging: Ideal for snacks, dried fruits, and other perishable items requiring extended shelf life. – Pharmaceutical Packaging: Provides essential protection for medications and health supplements. – Cosmetic Packaging: Enhances product presentation while safeguarding against external contaminants. – Industrial Uses: Suitable for various industrial applications where moisture and oxygen barriers are critical.

Conclusion:

As a reputable manufacturer with years of experience in the industry, we understand the importance of quality and reliability. Our Barrier Metallized OPP film is produced using advanced technology and stringent quality control measures to ensure that every roll meets the highest standards. This commitment to excellence has established us as a trusted exporter in the global market.

We offer competitive bulk prices for businesses looking to bulk buy our products. Whether you are a small enterprise or a large corporation, our wholesale options are designed to accommodate your specific needs. By choosing us as your OEM partner, you can benefit from customized solutions tailored to your unique requirements while enjoying significant cost savings.

Our Barrier Metallized OPP film is not only versatile but also eco-friendly, making it an excellent choice for companies committed to sustainability. With its superior performance characteristics and aesthetic appeal, this product is perfect for food packaging, cosmetics, electronics, and more.

Partner with us today and experience the advantages of sourcing from a leading manufacturer in China. As an established supplier and exporter, we are dedicated to providing you with high-quality products at competitive prices. Contact us now to discuss your bulk buying needs and discover how our Barrier Metallized OPP film can enhance your packaging solutions.