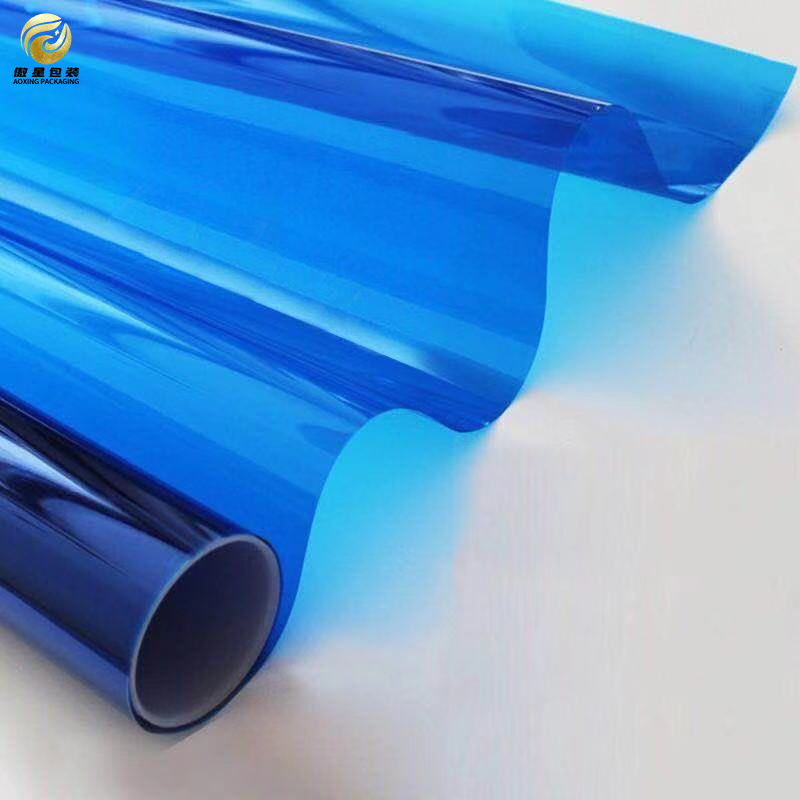

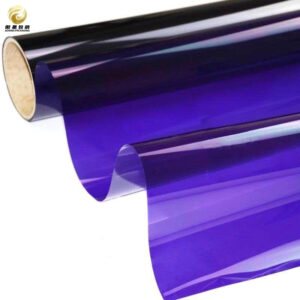

Película PET de alta claridad

| Producto | Film PET transparente |

| Material | PET + color+ capa de aluminio / PET + aluminio + capa de color |

| Espesor | 12~188um |

| Opción de color | Rojo, azul, púrpura, verde, oro, amarillo, rosa, arco iris, etc. |

| Anchura y longitud | Anchura:500~1800mm Longitud:Personalizada |

Descripciones detalladas

Introducing our High Clarity PET Film, a premium-grade polyester film engineered to deliver exceptional optical clarity and durability for a wide range of applications. This versatile material is designed to meet the rigorous demands of industries such as packaging, electronics, graphics, and more, making it an indispensable choice for professionals seeking reliability and performance.

Key Features:

1. Exceptional Optical Clarity: Our High Clarity PET Film boasts a remarkable transparency level, ensuring that colors remain vibrant and true to life. This feature is particularly beneficial for applications requiring visual appeal, such as product packaging and display graphics.

2. Superior Durability: Constructed from high-quality polyethylene terephthalate (PET), this film exhibits outstanding resistance to tearing, puncturing, and environmental stressors. Its robust nature ensures longevity in various conditions, making it ideal for both indoor and outdoor use.

3. Chemical Resistance: The High Clarity PET Film is engineered to withstand exposure to a variety of chemicals, oils, and solvents without compromising its integrity. This characteristic makes it suitable for applications in laboratories, manufacturing environments, and other settings where chemical exposure is a concern.

4. Thermal Stability: With excellent thermal stability, our PET film can endure a wide range of temperatures without warping or degrading. This property is essential for applications involving heat sealing or those subjected to fluctuating thermal conditions.

5. Easy Processing: The film can be easily processed through various methods such as printing, laminating, and die-cutting. Its compatibility with standard printing technologies allows for seamless integration into existing production workflows.

6. Eco-Friendly Option: Our High Clarity PET Film is recyclable and produced with environmentally responsible practices in mind. By choosing this product, you are not only investing in quality but also contributing to sustainable practices within your industry.

Applications:

The versatility of High Clarity PET Film makes it suitable for an array of applications including:

– Packaging Solutions: Ideal for food packaging, retail displays, and protective coverings that require high visibility. – Electronics: Used in screens and protective films where clarity and durability are paramount. – Graphics & Signage: Perfect for high-resolution printing needs in promotional materials and signage. – Industrial Uses: Employed in labels and overlays that demand resilience against wear and tear.

Conclusion:

Our High Clarity PET Film is ideal for applications ranging from packaging to electronics, offering superior optical clarity that enhances visibility while providing robust protection. This versatile film is perfect for businesses looking to bulk buy high-performance materials at competitive prices. By choosing us as your trusted exporter, you can rest assured that you are receiving a product that combines quality with value.

We understand the importance of flexibility in today’s market, which is why we offer OEM services tailored to your specific requirements. Whether you need custom sizes or unique specifications, our experienced team is ready to assist you in creating the perfect solution for your business needs.

For those interested in wholesale purchasing, we provide attractive bulk prices that allow you to maximize your investment while ensuring a steady supply of high-quality PET film. Our commitment to excellence as a producer means that every roll of film undergoes rigorous quality control processes before it reaches your facility.

In summary, our High Clarity PET Film stands out as an exceptional choice for businesses seeking reliability and performance. Partner with us today and experience the benefits of working with a reputable manufacturer dedicated to meeting your needs as a valued customer. Whether you are looking to bulk buy or require specific OEM solutions, we are here to support your business every step of the way.