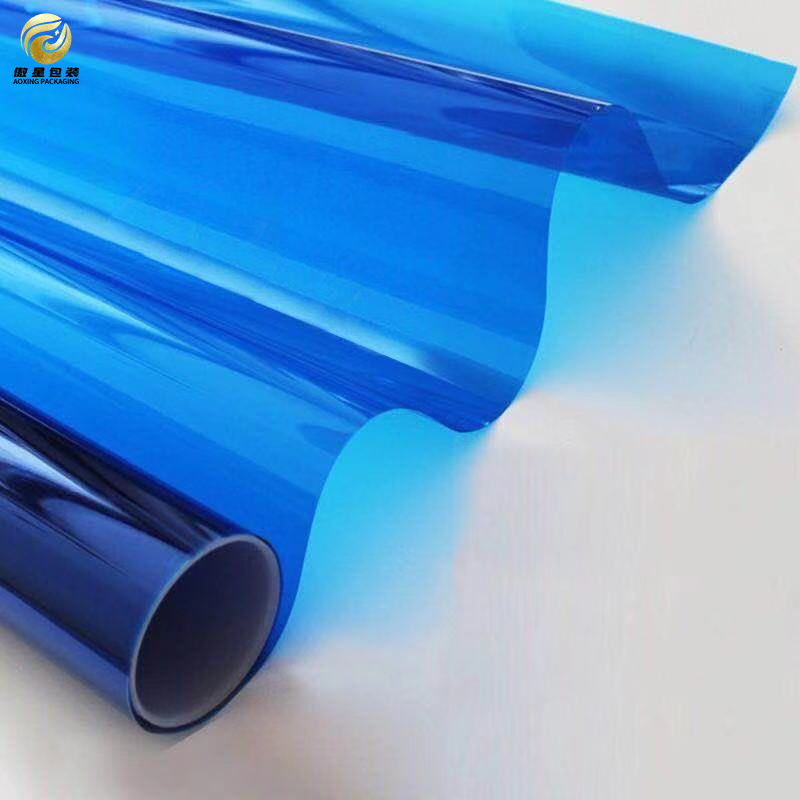

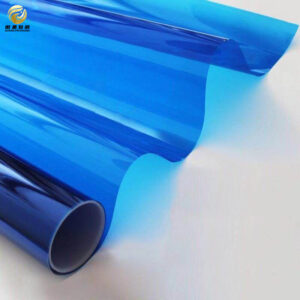

Film de poliéster brillante

| Producto | Película PET de alto brillo |

| Material | PET + color+ capa de aluminio / PET + aluminio + capa de color |

| Espesor | 12~188um |

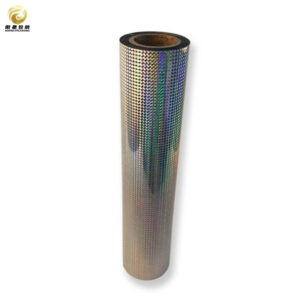

| Opción de color | Rojo, azul, púrpura, verde, oro, amarillo, rosa, arco iris, etc. |

| Anchura y longitud | Anchura:500~1800mm Longitud:Personalizada |

Descripciones detalladas

Product Description: Glossy Polyester Film

Introducing our premium Glossy Polyester Film, a versatile and high-performance material designed to meet the demanding needs of various industries. Engineered with precision, this film combines exceptional clarity, durability, and aesthetic appeal, making it an ideal choice for applications ranging from packaging to graphic displays.

Key Features:

1. Superior Clarity and Gloss Finish: Our Glossy Polyester Film boasts an ultra-clear surface that enhances visual appeal while providing a brilliant gloss finish. This feature ensures that colors appear vibrant and images are sharp, making it perfect for high-quality printing applications.

2. Exceptional Durability: Constructed from high-grade polyester, this film exhibits remarkable resistance to tearing, puncturing, and environmental factors such as moisture and UV light. Its robust nature ensures longevity in both indoor and outdoor settings, making it suitable for a wide range of applications.

3. Versatile Applications: The versatility of our Glossy Polyester Film makes it suitable for various uses including: – Packaging Solutions: Ideal for food packaging, retail displays, and product wraps that require both protection and aesthetic appeal. – Graphic Arts: Perfect for posters, banners, and promotional materials where visual impact is paramount. – Laminating: Excellent for laminating documents or photographs to enhance their durability while providing a sleek finish.

4. Easy Handling and Processing: Our film is designed for ease of use in various printing processes including digital printing, screen printing, and offset printing. It can be easily cut, folded, or shaped without compromising its integrity.

5. Eco-Friendly Options Available: We are committed to sustainability; therefore, we offer eco-friendly variants of our Glossy Polyester Film that meet environmental standards without sacrificing quality or performance.

6. Customizable Sizes and Thicknesses: Understanding that every project has unique requirements, we provide customizable options in terms of sizes and thicknesses to ensure you find the perfect fit for your specific needs.

7. Adhesive Compatibility: Our Glossy Polyester Film is compatible with a variety of adhesives, allowing for seamless integration into your existing production processes.

As an experienced exporter of specialty films, we offer competitive bulk prices for customers looking to bulk buy. Our commitment to quality and customer satisfaction makes us the preferred choice for businesses seeking reliable materials at wholesale rates. We also provide OEM services, allowing you to customize the film according to your specific requirements.

Whether you are a small business or a large corporation, our Glossy Polyester Film is available in various sizes and thicknesses to suit your needs. Partner with us today to experience the benefits of working with a reputable producer in the industry. Contact us for more information on bulk purchasing options and let us help you elevate your product offerings with our high-quality glossy polyester solutions.