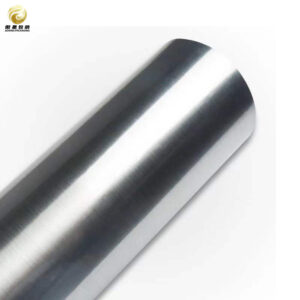

Película PET reflectante

| Producto | Película PET de alto brillo |

| Material | PET + color+ capa de aluminio / PET + aluminio + capa de color |

| Espesor | 12~188um |

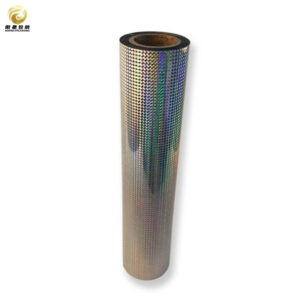

| Opción de color | Rojo, azul, púrpura, verde, oro, amarillo, rosa, arco iris, etc. |

| Anchura y longitud | Anchura:500~1800mm Longitud:Personalizada |

Descripciones detalladas

Product Description: Reflective PET Film

Introducing our premium Reflective PET Film, a versatile and high-performance material designed to meet the diverse needs of various industries. Engineered from high-quality polyethylene terephthalate (PET), this film boasts exceptional durability, clarity, and reflectivity, making it an ideal choice for applications ranging from packaging to signage and beyond.

Key Features:

1. Superior Reflectivity: Our Reflective PET Film is designed to maximize light reflection, ensuring that your products stand out in any environment. The film’s reflective properties enhance visibility, making it perfect for safety applications, promotional displays, and decorative purposes.

2. Exceptional Durability: Constructed from robust PET material, this film is resistant to tearing, puncturing, and environmental stressors. Its durability ensures that it maintains its integrity and performance over time, even in challenging conditions.

3. High Clarity and Transparency: The film offers excellent optical clarity, allowing for vibrant colors and sharp images to shine through. This feature is particularly beneficial for applications requiring high-quality graphics or visual displays.

4. Versatile Applications: Our Reflective PET Film is suitable for a wide range of uses, including: – Signage: Ideal for creating eye-catching signs that require enhanced visibility. – Packaging: Perfect for retail packaging solutions that demand both aesthetics and functionality. – Safety Gear: Utilized in the production of safety vests and gear where visibility is paramount. – Decorative Elements: Great for crafting and design projects that require a reflective finish.

5. Easy to Work With: The film can be easily cut, shaped, and adhered to various surfaces without compromising its reflective properties. Its compatibility with different printing techniques allows for customization tailored to your specific needs.

6. Eco-Friendly Option: Our Reflective PET Film is produced with sustainability in mind. It is recyclable and contributes to environmentally responsible practices within your business operations.

Specifications: – Thickness: Available in various thicknesses to suit different applications – Width: Customizable widths available upon request – Finish: Glossy or matte options to match your design requirements

Conclusion:

As a reputable manufacturer, we understand the importance of reliability and consistency in your supply chain. Our Reflective PET Film is available for bulk buy options, allowing businesses to take advantage of competitive wholesale pricing. By choosing us as your trusted exporter, you can ensure that you receive top-quality products at bulk prices that fit your budget.

We offer OEM services tailored to your specific requirements, ensuring that our Reflective PET Film meets your unique specifications. Whether you are looking for custom sizes or specific reflective properties, our dedicated team is here to assist you in achieving your project goals.

Partnering with us means gaining access to a reliable source of high-quality reflective materials. As a leading supplier in the industry, we are committed to providing exceptional customer service and support throughout your purchasing journey. Our extensive experience as a factory producer allows us to maintain strict quality control measures while delivering products that exceed expectations.

In summary, our Reflective PET Film is not only an excellent choice for enhancing visibility but also a smart investment for businesses looking to bulk buy high-quality materials at wholesale prices. Contact us today to learn more about how we can serve as your preferred manufacturer and exporter of Reflective PET Film. Let us help you illuminate your projects with our superior reflective solutions.