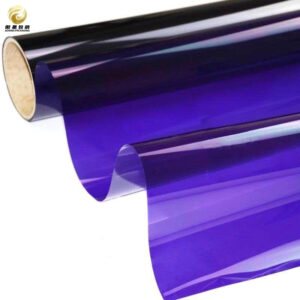

Película PET con acabado de alto brillo

| Producto | Película PET de alto brillo |

| Material | PET + color+ capa de aluminio / PET + aluminio + capa de color |

| Espesor | 12~188um |

| Opción de color | Rojo, azul, púrpura, verde, oro, amarillo, rosa, arco iris, etc. |

| Anchura y longitud | Anchura:500~1800mm Longitud:Personalizada |

Descripciones detalladas

Product Description: High Gloss PET Film

Elevate your packaging and display solutions with our premium High Gloss PET Film, a versatile and high-performance material designed to meet the demanding needs of various industries. Engineered from top-quality polyethylene terephthalate (PET), this film combines exceptional clarity, durability, and aesthetic appeal, making it an ideal choice for applications ranging from food packaging to promotional materials.

Key Features:

1. Superior Clarity and Gloss: Our High Gloss PET Film boasts an unparalleled glossy finish that enhances visual appeal, ensuring that your products stand out on the shelves. The crystal-clear surface allows for vibrant color reproduction and sharp image quality, making it perfect for high-resolution graphics and intricate designs.

2. Exceptional Durability: This film is engineered to withstand the rigors of everyday use. Its robust structure provides excellent resistance to tearing, puncturing, and moisture, ensuring that your packaging remains intact and visually appealing throughout its lifecycle. The high gloss finish also offers resistance to scratches and scuffs, maintaining a pristine appearance even in challenging environments.

3. Versatile Applications: The High Gloss PET Film is suitable for a wide range of applications across various sectors. Whether you are looking to create eye-catching labels, flexible packaging, or high-quality displays, this film adapts seamlessly to your needs. Its compatibility with various printing techniques—including flexography, lithography, and digital printing—ensures that you can achieve the desired results with ease.

4. Eco-Friendly Option: As sustainability becomes increasingly important in today’s market, our High Gloss PET Film stands out as an eco-friendly choice. Made from recyclable materials, it aligns with environmentally conscious practices without compromising on performance or quality.

5. Easy Handling and Processing: Designed for efficiency, our High Gloss PET Film is easy to handle and process. It can be easily cut, laminated, or converted into various formats without losing its structural integrity or gloss finish. This user-friendly characteristic makes it an ideal choice for manufacturers looking to streamline their production processes.

6. Customizable Solutions: We understand that every project is unique; therefore, we offer customizable options tailored to your specific requirements. From varying thicknesses to custom sizes and finishes, our team is dedicated to providing solutions that meet your exact specifications.

Conclusion:

As a reputable exporter with extensive experience in international trade, we understand the importance of reliability and efficiency in supply chain management. Our factory is equipped to handle both small and large-scale orders, making us an ideal partner for businesses looking to bulk buy high-quality PET film at competitive prices. We offer attractive wholesale options tailored to meet your specific requirements.

For companies seeking customized solutions, we provide OEM services that allow you to tailor the specifications of our High Gloss PET Film to suit your unique applications. Our commitment to quality ensures that every roll meets rigorous standards before it reaches your facility.

When you choose our High Gloss PET Film, you benefit from bulk pricing that maximizes your investment while ensuring you receive a product that delivers superior performance. Partner with us today and experience the difference of working with a trusted producer dedicated to excellence in every aspect of production and service.

In summary, our High Gloss PET Film is not just a product; it’s a commitment to quality and innovation from a leading manufacturer in China. Contact us today for more information on how we can support your business needs through our exceptional offerings as a supplier and exporter in the industry.