What Are Metalized Films and How Are They Classified Based on Types and Materials?

Metalized films are a kind of plastic film coated with a very thin layer of metal. This layer gives the film a shiny, reflective surface and also improves its barrier against moisture, gases, and light. Common metals used for coating are aluminum, copper, silver, and zinc. Each metal brings its own unique properties to the film.

What Is a Metalized Film? Definition and Structure

A metalized film is made by depositing a thin metal layer on a plastic film substrate. The plastic acts as a strong, flexible base, while the metal adds barrier functions and a reflective finish. The metal layer is often just 1% of the total film thickness, but it greatly enhances the film's performance. The metal coating:

- Blocks oxygen and moisture, preserving food and other sensitive products

- Reflects light, improving insulation and visual appeal

- Adds mechanical strength and durability

Typical structure:

| Layer | Purpose | Examples |

|---|---|---|

| Metal layer | Barrier and reflectivity | Aluminum, silver, copper |

| Polymer substrate | Flexibility and toughness | Polyester (PET), polypropylene (PP), polyethylene (PE) |

How Are Metalized Films Made? Vacuum Metallization and Coating

The key manufacturing method is vacuum metallization. Here’s how it works:

- The plastic film moves into a vacuum chamber.

- The chosen metal is heated until it vaporizes.

- Metal vapor condenses on the cold film surface, forming a thin, even metallic coating.

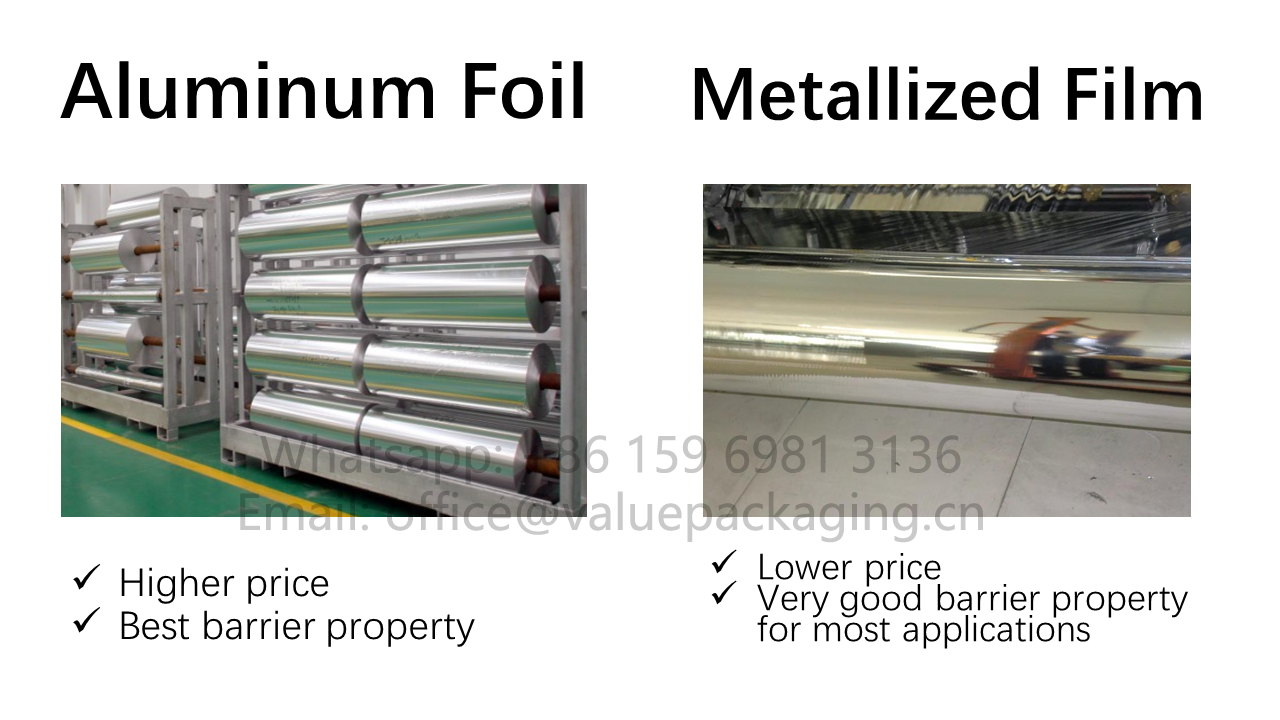

This process avoids damaging the plastic with heat or chemicals. It creates a uniform metallic layer only a few nanometers thick. Compared to aluminum foil, metalized films use much less metal — about 1% of the amount — making them lighter and more cost-effective.

Other coating methods include sputtering and electroplating, but vacuum metallization is most common for flexible films.

Primary Types of Metalized Films

There are several main metalized film types, classified by their base polymer and metal:

-

Aluminum Metalized Film

- The most popular type. Aluminum adds a strong barrier against moisture, oxygen, and light. Used widely in food packaging to keep products fresh.

-

Vacuum Metallized Film

- Refers broadly to films coated by vacuum metallization. Coatings may be aluminum or other metals. Used in packaging and insulation.

-

Metallized Polypropylene (PP)

- Polypropylene is strong, heat resistant, and moisture-resistant. Metallizing PP improves barrier properties and adds shine. Ideal for snacks and flexible packaging.

-

Metallized Polyester (PET)

- PET films have high tensile strength and heat resistance. Metallized PET combines these properties with barrier and decorative appeal. Used in snack wrappers, beverage packaging, and insulation films.

-

Metallized Polyethylene (PE)

- PE is flexible and moisture resistant. Metallized PE offers a low-cost solution for packaging like bread bags and snack wrappers, balancing performance and cost.

Physical and Chemical Properties Unique to Metalized Film Types

| Film Type | Key Properties | Common Uses |

|---|---|---|

| Aluminum Metalized Film | Excellent barrier, reflective, heat resistant | Food packaging, insulation, decorative |

| Metallized Polypropylene | Moisture resistant, strong tensile, heat sealable | Snack packaging, bakery goods |

| Metallized Polyester | High strength, tear resistance, printable | Flexible packaging, beverages, pharma |

| Metallized Polyethylene | Cost-effective, moisture barrier, flexible | Snack bags, bread packaging |

Each polymer substrate adds its own mechanical and chemical strengths. For example, PET’s high tensile strength supports packaging that needs durability. PP offers good heat sealability, useful in food packaging. PE is flexible and cheaper but less strong.

How Metal Coatings Affect Properties and Performance

The choice of metal dramatically affects the film's barrier and appearance:

-

Aluminum

- Most common, provides a strong barrier against oxygen, moisture, and light. Also reflective, improving thermal insulation.

-

Copper

- Less common, used when thermal or electrical conductivity is important. Found in electronics and decorative films.

-

Silver

- Offers superior reflectivity and electrical conductivity. Used in solar control films and reflective insulation.

-

Zinc

- Has anti-microbial properties, making it useful in hygienic food packaging and agricultural films.

The metal coating’s thickness affects performance. Thicker layers improve barrier qualities but increase cost and reduce transparency.

Common Polymer Substrates and Their Influence

The type of polymer substrate controls the film’s flexibility, strength, and compatibility:

| Polymer | Properties | Influence on Metalized Film |

|---|---|---|

| Polyester (PET) | Strong, heat resistant, printable | Tough films, good for packaging needing durability and print quality |

| Polypropylene (PP) | Heat sealable, moisture resistant | Flexible, seals well, ideal for snacks and bakery packaging |

| Polyethylene (PE) | Flexible, low cost | Good moisture barrier, economical choice for flexible packaging |

Substrate choice also affects machinability and sealing behavior of the final metalized film.

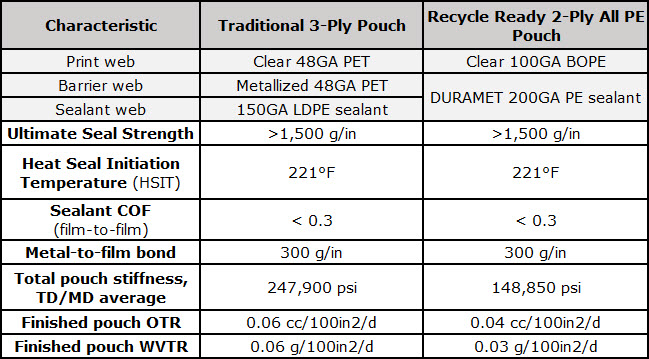

Multilayer Laminates and Enhanced Properties

Metalized films are often part of multilayer laminates. Multiple layers combine plastics and metals to improve:

- Barrier properties: Keeps moisture and oxygen out

- Mechanical strength: Resists punctures and tearing

- Heat sealability: Adds secure sealing for packaging

For example, a laminate may combine metallized PET with polyethylene for sealing and printability. These structures meet the growing demand in markets like India’s packaging sector, which is expected to grow at a CAGR of 26.7% due to safety and contamination concerns.

Environmental Considerations and Biodegradability

Standard metalized films are not biodegradable because of the plastic base and metal coating. However, new options like metalized oxo-biodegradable films are entering the market. These films contain additives that help them degrade under certain conditions.

Oxo-biodegradable films offer a balance between performance and environmental impact, meeting consumer demand for greener packaging.

Metalized films are a versatile group of materials. They differ by metal type, polymer substrate, and manufacturing method. This affects their barrier, mechanical, optical, and environmental properties. Understanding these differences helps us better compare different types of metalized films based on applications and properties.

How Do Different Metalized Films Compare in Terms of Applications and Industry Uses?

Metalized films are used in many industries today due to their unique combination of barrier protection and flexibility. Let’s explore the common applications and key industry uses of metalized films to see how their properties match different needs.

Main Industries Using Metalized Films

The metalized films industry is broad, but the main sectors include:

- Packaging: Dominates use due to barrier properties and visual appeal.

- Electronics: Used for insulation, reflectivity, and conductivity.

- Thermal Insulation: In buildings and vehicles for heat reflection and retention.

- Agriculture: For greenhouse films and crop protection.

- Decorative Laminates: Automotive interiors, furniture, and brand labels.

These industries rely on metalized films to boost performance, enhance durability, and improve aesthetics.

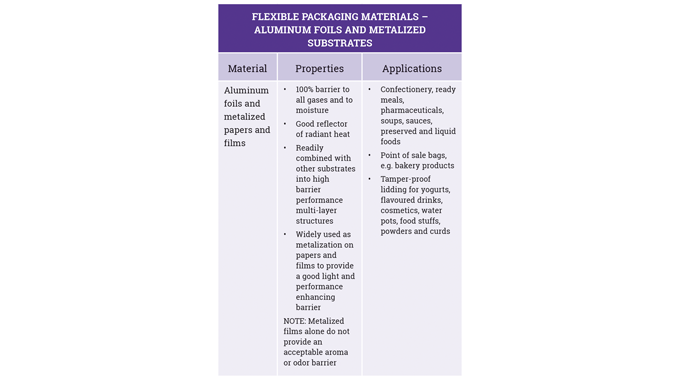

How Metalized Films Enhance Food Packaging

Metalized films excel in food packaging because they serve as excellent barriers to oxygen, moisture, and light. This helps:

- Extend Shelf Life: Keeping food fresh longer by blocking air and humidity.

- Protect Against Contamination: Shielding from microbes and pollutants.

- Maintain Product Quality: Preventing flavor loss and spoilage.

Food packaging growth in India, expected to rise around 26.7% CAGR over the next five years, is powered by demand for contamination-resistant metalized packaging.

Ideal Metalized Films for Snack, Bakery, Beverage, and Pharma Packaging

Different metalized films fit specific packaging needs based on flexibility, machinability, and barrier properties:

| Metalized Film Type | Typical Use | Why It’s Ideal |

|---|---|---|

| Metalized Cavitated White Opaque Film | Snacks, bakery products | Bright white base, excellent moisture and oxygen barriers |

| Metalized Oxo-Biodegradable Heat Sealable Film | Pharma and eco-conscious packaging | Oxo-biodegradable, heat-sealable for secure closure |

| Metalized Barrier Films | Beverage pouches, health & beauty packs | Solvent-free, strong barrier, supports lamination |

| Polyester Metalized Films (MPET) | Pharmaceutical blisters and flexible packaging | High tensile strength, good printability, heat sealable |

These films let brands offer functional, safe, and attractive packaging that draws customers.

Applications in Electronics

Metalized films play vital roles in electronics for both protective and functional reasons:

- Thermal Insulation: Reflect heat away in devices like batteries to enhance safety.

- Battery Insulation: Prevent short circuits and improve energy efficiency.

- RFID Tags: Use thin aluminum coatings for signal transmission.

- Reflective Coatings: Applied in displays and solar panels for better light management.

Aluminum and silver metalized films are favorites here for their thermal and electrical conductivity.

Role in Thermal Insulation for Buildings and Vehicles

By reflecting infrared radiation, metalized films reduce heat transfer. This makes them great for:

- House Insulation: Lowering energy consumption for cooling and heating.

- Vehicle Interiors: Cutting heat buildup, enhancing passenger comfort.

Their lightweight nature and durability surpass traditional insulation materials in many cases.

Contribution to Agricultural Applications

In agriculture, metalized films improve the microclimate for plants and protect crops:

- Greenhouse Films: Reflect excess heat while letting in light, boosting growth.

- Mulch Films: Block weed growth and preserve soil moisture.

- Anti-Microbial Zinc Metalized Films: Reduce bacterial growth on crop surfaces.

These properties maximize yield and reduce the need for chemical treatments.

Benefits in Label Manufacturing and Printability

Labels printed on metalized films gain:

- High Optical Density: Sharp, vibrant graphics that stand out on shelves.

- Heat Sealability: Enables secure wrapping and handling.

- Compatibility with Multiple Printing Techniques: Flexography, UV, letterpress, and offset print easily on metalized substrates.

BOPP-based Metalized Wrap Around Label Films are widely used by beverage companies globally, offering clarity, stiffness, and mould resistance.

Emerging Design Trends Impacting Branding and Consumer Appeal

Designers embrace several current trends in metalized films that enhance brand identity:

- Bold Metallic Colors: Copper, gold, silver, rose gold create eye-catching looks.

- Geometric Patterns and Futuristic Aesthetics: Evoke a sense of technology and innovation.

- Natural and Organic Motifs: Signal eco-friendliness to consumers.

- Minimalistic Typography with Metallic Shine: Combines elegance and modern appeal.

These trends show how metalized films are not just functional but also vital to brand storytelling and attraction.

Metalized films truly stand out because they blend practical barrier properties with visual brilliance. Their use spans sectors from protecting fresh food to enabling high-tech electronics. By choosing the right metalized film type, industries can boost preservation, printing quality, and overall product appeal effectively.

What Performance Characteristics and Advantages Differentiate Metalized Films Across Applications?

When you compare different types of metalized films based on applications and properties, several key performance features stand out. Metalized films are valued for their excellent barrier properties, mechanical strength, visual appeal, and cost-effectiveness. Below, I break down how these factors vary across metalized film types and how they stack up against traditional materials like aluminum foil.

Barrier Properties Against Oxygen, Moisture, and Light

One crucial property of metalized films is their barrier ability. This controls how well they protect products from oxygen, moisture, and light—all of which can cause spoilage, reduce shelf life, or degrade product quality.

| Film Type | Oxygen Barrier | Moisture Barrier | Light Barrier | Typical Applications |

|---|---|---|---|---|

| Aluminum Metalized Polyester | Excellent | Good | Excellent | Food packaging, pharmaceutical wraps |

| Metallized Polypropylene (MPP) | Very Good | Excellent | Good | Snack packaging, baked goods |

| Metallized Polyethylene (MPE) | Moderate | Good | Moderate | Cost-effective snack packs |

| Vacuum Metallized Films (MPET) | Very Good | Good | Excellent | Flexible packaging, labels |

| Aluminum Foil | Outstanding | Outstanding | Outstanding | Long-term food storage, trays, insulation |

Aluminum foil provides the highest barrier to moisture and gases but is heavier and less flexible. Metalized films, such as MPET and metallized polyester, offer excellent barriers while being lightweight and flexible. The barrier strength depends on the metal layer thickness, typically 99.98% pure aluminum deposited via vacuum metallization. This layer blocks oxygen and light well, but metalized films generally allow slightly more gas transmission than foil.

Thermal and Mechanical Properties

Thermal and mechanical features affect how metalized films perform under stress, in heat sealing, or when stretched. These include tensile strength, tear resistance, and heat sealability.

- Tensile Strength: Metallized polyester films stand out with high tensile strength and durability. This makes them ideal for packaging that faces handling or transport stresses.

- Tear Resistance: Metallized polypropylene exhibits strong tear resistance, suitable for snack and bakery packaging.

- Heat Sealability: Metalized oxo-biodegradable heat sealable films offer secure sealing at moderate temperatures. This property ensures freshness and prevents contamination in food packs.

Aluminum foil does not heat seal on its own. It requires lamination with polymers, increasing stiffness but reducing flexibility. Metalized films combine metal’s barrier with polymers’ heat sealing capability, aiding in automated packaging lines.

Comparison with Aluminum Foil: Flexibility, Weight, and Environmental Impact

When stacked against aluminum foil, metalized films shine in flexibility and weight.

| Feature | Metalized Films | Aluminum Foil |

|---|---|---|

| Flexibility | High; bends without cracking | Lower; prone to cracks and creases |

| Weight | 2-3 times lighter | Heavier |

| Aluminum Content | About 1% of foil’s aluminum content | 100% aluminum |

| Environmental | More sustainable; some oxo-biodegradable options | Higher carbon footprint due to mining & refining |

This flexibility and lower weight reduce shipping costs and carbon emissions. The environmental effects favor metalized films due to lower aluminum usage and newer biodegradable options.

Aesthetic Benefits in Packaging and Decoration

Metalized films score high in aesthetics due to their shiny, eye-catching metallic finishes. Brands can use metallic colors like silver, gold, copper, and rose gold to boost shelf appeal.

- These films support bold metallic colors and geometric patterns, keeping up with 2023 design trends.

- The smooth reflective surface enhances print quality and allows diverse ink types such as flexography, UV, and offset printing.

- Applications include luxury cosmetics, snack wrappers, beverages, and decorative laminates for automotive interiors.

Cost-Effectiveness and Sustainability

Cost plays a major role when selecting materials.

- Metalized films are often cheaper than foil laminates but offer many similar benefits.

- Reduced material weight means less packaging waste and shipping expenses.

- Oxo-biodegradable metalized films add sustainability without soaring costs.

- Using solvent-free coated barrier films in laminates can shrink material usage, cutting costs and waste.

Machinability and Printing Compatibility

Metalized films vary in how they handle printing and machinery.

| Metalized Film Type | Machine Speed | Printing Techniques Compatible |

|---|---|---|

| Metalized Polyester | High | Flexography, UV, letterpress, offset |

| Metallized Polypropylene | Medium | Mainly flexography and solvent-based inks |

| Metalized Wrap Around Label Films (BOPP-based) | Very High | Flexography, UV curing, heat sealable on reverse |

| Vacuum Metallized Films (MPET) | Moderate | Good adhesion with primers, multiple ink chemistries |

Good machinability means films run smoothly on high-speed packaging and labeling lines without tearing or jamming. Compatibility with multiple printing methods supports luxury brands needing sharp, vibrant graphics.

Challenges and Limitations

Despite their benefits, metalized films have drawbacks.

- Metal layer can be prone to abrasion, damaging barrier properties.

- Lower gas barrier than pure aluminum foil limits ultra long-term food preservation.

- Some metalized films do not biodegrade naturally, causing environmental concerns.

- Heat sealability varies; some films require combination with other polymers.

- Metalized films may face regulatory scrutiny in food packaging, especially concerning migration limits of metals and coatings.

Food Safety and Regulatory Compliance

Metalized films applied in food packaging must meet strict standards.

- They generally comply with FDA and Indian food safety norms concerning metal migration and contaminant levels.

- Many metalized food packaging films are tested for microbial resistance, ensuring product hygiene.

- Barrier against oxygen and moisture significantly extends shelf life and keeps perishables safe.

- Films like metalized oxo-biodegradable types offer a balance of protection and ecological compatibility.

These detailed comparisons show that choosing the right metalized film depends on the specific application needs. You balance barrier strength, mechanical traits, environmental impact, cost, printability, and regulatory factors to optimize packaging and product success.

FAQs about Compare different types of metalized films based on applications and properties

What are metalized films and how are they classified based on types and materials?

Metalized films are plastic films coated with a very thin metal layer, such as aluminum, copper, silver, or zinc, which enhances barrier properties, reflectivity, and mechanical strength; they are classified by their metal type and polymer substrate like polyester (PET), polypropylene (PP), and polyethylene (PE).

How are metalized films manufactured?

Metalized films are primarily made by vacuum metallization, where metal is vaporized in a vacuum chamber and condenses uniformly on a plastic film, creating a thin metallic layer that enhances barrier and reflective properties while keeping the film lightweight and flexible.

What are the main applications of metalized films across industries?

Metalized films are widely used in packaging for food, snacks, pharmaceuticals, and beverages; in electronics for insulation and reflectivity; in thermal insulation for buildings and vehicles; in agriculture for crop protection; and in decorative laminates for branding and aesthetics.

How do different metal coatings affect the performance of metalized films?

Different metals impact performance uniquely: aluminum provides strong moisture, oxygen, and light barriers with high reflectivity; silver offers superior reflectivity and conductivity; copper is valued for thermal and electrical conductivity; zinc imparts anti-microbial properties for hygienic packaging.

How do metalized films compare to aluminum foil in terms of flexibility, weight, and environmental

Metalized films come in many types and use different metals like aluminum and copper. Each type has unique features that fit specific needs in packaging, electronics, and more. Their strong barrier and thermal traits protect products better than many alternatives. Choosing the right film depends on your project’s demands and the balance between cost and performance. Understanding these details helps you pick solutions that work well and last longer. Metalized films show how smart design meets real-world needs across industries.