OPP FILMS

-

Aluminum Coated OPP Film

-

Aluminumized film

-

Barrier Metallized OPP

-

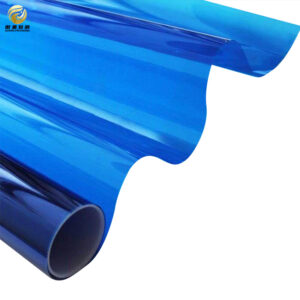

Clear Plastic OPP Film

-

Clear Polypropylene Film

-

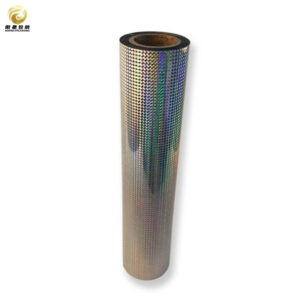

Decorative Holographic OPP Film

-

Dull Finish OPP Film

-

High Transparency OPP Film

-

Hologram Polypropylene Film

-

Holographic Effect OPP Film

-

Holographic Lamination OPP Film

-

Low-Gloss OPP Film

-

Matte Finish Polypropylene Film

-

Metallized Oriented Polypropylene Film

-

Non-Glossy Polypropylene Film

-

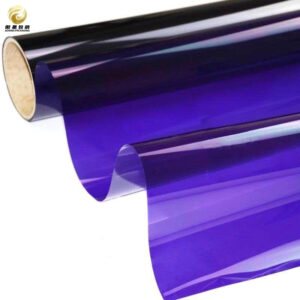

Rainbow OPP Film

More colors and options available

About OPP Films

OPP film, also known as Oriented Polypropylene film, is a widely used material in the packaging industry. It plays a crucial role in protecting and preserving various products, ranging from food items to consumer goods. The versatility and effectiveness of OPP film make it an essential component in packaging solutions. In this article, we will explore the different aspects of OPP film, including its manufacturing process, advantages, types available in the market, comparison with other packaging materials, applications in the food industry, role in sustainable packaging solutions, environmental impact, innovations in technology, tips for choosing the right OPP film, proper storage and handling techniques, and future trends in the packaging industry.

What is OPP film and how is it made?

OPP film is a type of plastic film made from polypropylene resin. It is produced through a process called biaxial orientation, which involves stretching the film in both machine and transverse directions. This stretching aligns the molecules of the polypropylene resin, resulting in a film with enhanced strength and clarity. The manufacturing process begins with melting the polypropylene resin and extruding it through a flat die to form a thin sheet. The sheet is then stretched in both directions using heated rollers or tenter frames. After stretching, the film is cooled and wound into rolls for further processing or packaging.

The advantages of using OPP film in packaging

One of the key advantages of using OPP film in packaging is its durability and strength. The biaxial orientation process gives OPP film excellent tensile strength, making it resistant to tearing and puncturing. This ensures that products packaged with OPP film are well-protected during transportation and handling.

Another advantage of OPP film is its transparency and clarity. Unlike some other packaging materials, OPP film provides a clear view of the packaged product, allowing consumers to see what they are buying. This transparency also makes OPP film an ideal choice for products that require visual appeal, such as confectionery items or gift packaging.

OPP film is also known for its resistance to moisture and oxygen. This barrier property helps to extend the shelf life of perishable products by preventing moisture absorption and oxygen ingress. Additionally, OPP film provides a good barrier against odors and flavors, ensuring that the packaged product retains its original taste and aroma.

Furthermore, OPP film is cost-effective compared to other packaging materials. Its production process is relatively simple and efficient, resulting in lower manufacturing costs. This cost advantage makes OPP film an attractive option for businesses looking to optimize their packaging expenses without compromising on quality.

The different types of OPP film available in the market

| Type of OPP Film | Thickness (microns) | Transparency | Strength | Applications |

|---|---|---|---|---|

| Biaxially Oriented Polypropylene (BOPP) | 15-50 | High | High | Food packaging, adhesive tapes, labels, cigarette packaging |

| Cast Polypropylene (CPP) | 20-60 | Medium | Low | Food packaging, laminates, flower wrapping, stationery |

| Metalized OPP (MOPP) | 20-50 | Low | Medium | Food packaging, gift wrapping, decorative films |

| Retortable OPP (R-OPP) | 50-100 | High | High | Retort pouches, microwaveable food packaging |

There are several types of OPP film available in the market, each with its own unique properties and applications.

Plain OPP film is the most common type and is widely used in various packaging applications. It offers excellent clarity, strength, and moisture resistance, making it suitable for a wide range of products.

Metallized OPP film has a thin layer of metal deposited on one side, giving it a metallic appearance. This type of OPP film provides enhanced barrier properties against light, moisture, and oxygen. It is often used for packaging products that require protection from UV radiation or require an extended shelf life.

Co-extruded OPP film is made by combining multiple layers of OPP film with different properties. This allows manufacturers to create films with specific characteristics such as enhanced barrier properties or improved sealability. Co-extruded OPP films are commonly used in applications where multiple functionalities are required.

White OPP film is a specialty type of OPP film that has an opaque white appearance. It is often used for packaging products that require high opacity or need to block out light. White OPP film is commonly used in applications such as labels, stickers, or window envelopes.

OPP film vs other packaging materials: a comparison

When comparing OPP film with other packaging materials such as PVC, PET, and LDPE films, there are several factors to consider.

In terms of durability and strength, OPP film is comparable to PVC and PET films. However, it has an advantage over LDPE film, which is less resistant to tearing and puncturing. This makes OPP film a preferred choice for packaging products that require high strength and protection.

In terms of transparency and clarity, OPP film outperforms PVC and LDPE films. While PET film offers similar transparency, it is often more expensive than OPP film. Therefore, OPP film is a cost-effective option for products that require a clear view of the packaged item.

When it comes to moisture and oxygen resistance, OPP film provides similar barrier properties as PVC and PET films. LDPE film, on the other hand, has lower barrier properties and is more permeable to moisture and oxygen. Therefore, OPP film is a better choice for products that require extended shelf life or protection against moisture and oxygen.

While OPP film offers numerous advantages, it also has some disadvantages compared to other packaging materials. For example, PVC film has better heat resistance than OPP film, making it suitable for applications that require high-temperature resistance. PET film also has better dimensional stability than OPP film, making it more suitable for applications that require precise dimensions.

How OPP film is used in the food industry

OPP film plays a crucial role in the food industry by providing safe and reliable packaging solutions for various food products. Its unique properties make it an ideal choice for packaging perishable items such as snacks, confectionery, bakery products, and frozen foods.

OPP film is commonly used for flexible packaging applications such as pouches, bags, wrappers, and labels. Its excellent barrier properties help to protect food products from moisture, oxygen, light, and odors. This ensures that the quality and freshness of the food are maintained throughout its shelf life.

In addition to its barrier properties, OPP film is also compliant with food safety regulations. It is approved for direct contact with food and does not release any harmful substances that could contaminate the packaged product. This makes OPP film a safe and reliable choice for food packaging.

The role of OPP film in sustainable packaging solutions

As the demand for sustainable packaging solutions continues to grow, OPP film has emerged as a viable option due to its recyclability and biodegradability.

OPP film can be recycled and reused, reducing the amount of waste generated from packaging materials. Recycling OPP film involves collecting used film, cleaning it, and processing it into new film or other plastic products. This helps to conserve resources and reduce the environmental impact of packaging waste.

Furthermore, OPP film can also be biodegradable under certain conditions. Biodegradable OPP films are designed to break down into natural elements when exposed to specific environmental conditions such as heat, moisture, and microorganisms. This allows them to decompose without leaving behind harmful residues.

In addition to recyclability and biodegradability, some manufacturers are also incorporating recycled materials into the production of OPP film. By using recycled polypropylene resin, the environmental impact of OPP film production can be further reduced.

The impact of OPP film on the environment

While OPP film offers several sustainable features, there are also environmental concerns associated with its production and disposal.

The production of OPP film requires energy and resources, including fossil fuels. The extraction and processing of these resources contribute to carbon emissions and other environmental impacts. Additionally, the disposal of OPP film can contribute to plastic waste if not properly managed.

To mitigate these concerns, measures can be taken to reduce the environmental impact of OPP film. This includes optimizing the manufacturing process to minimize energy consumption and waste generation. Additionally, promoting responsible disposal practices such as recycling or proper waste management can help reduce the environmental footprint of OPP film.

Innovations in OPP film technology

The OPP film industry is constantly evolving, with new developments and innovations in technology. These advancements aim to improve the performance, functionality, and sustainability of OPP film.

One of the recent developments in OPP film production is the use of nano-additives. These additives, such as nanoparticles or nanoclays, are incorporated into the film to enhance its barrier properties, mechanical strength, or other functionalities. This allows manufacturers to create films with improved performance and reduced material usage.

Another emerging trend in OPP film technology is the development of bio-based polypropylene resins. These resins are derived from renewable sources such as plant-based feedstocks, reducing the reliance on fossil fuels. Bio-based OPP films offer similar properties and performance as traditional OPP films while providing a more sustainable alternative.

Furthermore, advancements in coating technologies have enabled the development of functional coatings for OPP films. These coatings can provide additional functionalities such as anti-fog properties, anti-static properties, or improved printability. This allows manufacturers to customize OPP films for specific applications and enhance their overall performance.

Tips for choosing the right OPP film for your product

When selecting OPP film for your packaging needs, there are several factors to consider.

Firstly, consider the specific requirements of your product. Determine if you need a high barrier film for moisture or oxygen protection, or if transparency and clarity are more important. Understanding the specific needs of your product will help you choose the right type of OPP film.

Secondly, consider the processing requirements of your packaging line. Different types of OPP films may have different sealing properties or compatibility with certain packaging machinery. Ensure that the chosen OPP film is compatible with your existing equipment to avoid any production issues.

Thirdly, consider the cost-effectiveness of the chosen OPP film. While OPP film is generally cost-effective compared to other packaging materials, there may be variations in pricing depending on the specific type and supplier. Compare prices and quality to find the best balance between cost and performance.

Lastly, consider the environmental impact of the chosen OPP film. Look for suppliers that offer recycled or biodegradable options, or those that have implemented sustainable practices in their manufacturing processes. Choosing an environmentally friendly OPP film can align with your company’s sustainability goals and contribute to a greener packaging solution.

How to properly store and handle OPP film

Proper storage and handling of OPP film are essential to maintain its quality and performance.

When storing OPP film, it is important to keep it in a clean, dry, and well-ventilated area. Exposure to moisture or high humidity can affect the properties of the film, such as its barrier properties or dimensional stability. Additionally, avoid storing OPP film near sources of heat or direct sunlight, as this can cause the film to warp or degrade.

When handling OPP film, it is important to take precautions to prevent damage. Avoid dragging or dropping the film, as this can cause tears or punctures. Use appropriate handling equipment such as pallet jacks or forklifts to move large rolls of OPP film. Additionally, ensure that the film is handled with clean hands or gloves to prevent contamination.

Future trends in OPP film and packaging industry

The future of OPP film and the packaging industry is expected to be driven by several trends.

One of the key trends is the increasing demand for sustainable packaging solutions. As consumers become more conscious of their environmental impact, there is a growing need for packaging materials that are recyclable, biodegradable, or made from renewable resources. This trend will likely drive further innovations in OPP film technology, such as the development of bio-based resins or improved recycling processes.

Another trend is the integration of smart packaging technologies. Smart packaging involves incorporating sensors, indicators, or tracking devices into packaging materials to provide real-time information about the product’s condition or location. This can help improve supply chain efficiency, reduce waste, and enhance consumer experience. OPP film can be adapted to accommodate these smart packaging technologies, making it a versatile choice for future packaging needs.

Furthermore, the rise of e-commerce and online shopping is expected to drive the demand for protective packaging solutions. OPP film can play a crucial role in providing secure and visually appealing packaging for products shipped through e-commerce channels. This trend will likely lead to the development of new OPP film formulations or structures that offer enhanced protection and convenience for online retailers and consumers.

In conclusion, OPP film is a versatile and important material in the packaging industry. Its durability, transparency, resistance to moisture and oxygen, and cost-effectiveness make it an ideal choice for various applications. With different types available in the market, businesses can choose the right OPP film to meet their specific packaging needs. While there are environmental concerns associated with OPP film, measures can be taken to reduce its impact through recycling, biodegradability, and the use of recycled materials. As technology continues to advance, OPP film will likely evolve to meet the changing demands of the packaging industry, offering more sustainable and innovative solutions for businesses worldwide.

FAQs

What is OPP film?

OPP film stands for Oriented Polypropylene film. It is a type of plastic film made from polypropylene resin that has been stretched and oriented in both machine and transverse directions.

What are the properties of OPP film?

OPP film is known for its high tensile strength, clarity, and resistance to moisture, grease, and chemicals. It is also heat-sealable and has good printability.

What are the applications of OPP film?

OPP film is widely used in the packaging industry for food, pharmaceuticals, and consumer goods. It is also used for lamination, labels, and adhesive tapes.

How is OPP film made?

OPP film is made by extruding molten polypropylene resin through a flat die and then stretching it in both machine and transverse directions. This process orients the polymer molecules and gives the film its unique properties.

What are the different types of OPP film?

There are several types of OPP film, including plain OPP film, metallized OPP film, coated OPP film, and white opaque OPP film. Each type has its own specific properties and applications.

Is OPP film recyclable?

Yes, OPP film is recyclable. However, it is important to check with local recycling facilities to see if they accept OPP film and to follow their guidelines for proper disposal.

Why choose us

Importing from us, a Chinese metalized film factory, provides cost-effective solutions, access to advanced technology, a wide range of customization options, and reliable production capabilities, ensuring high-quality products at competitive prices.

High-quality, durable films for reliability and performance

Customization options offered to meet unique project requirements.

Competitive pricing ensures cost-effectiveness for customers.

Responsive customer service for a seamless experience and satisfaction.