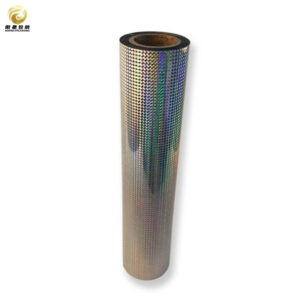

Holographic OPP Film

More colors and options available

About Holographic OPP Film

Holographic OPP Film is a type of film that is used for various applications, including packaging, branding, and security. It is made from oriented polypropylene (OPP), which is a versatile and durable material. The film is coated with a holographic layer, which creates a three-dimensional effect when light is reflected off its surface.

The concept of holography dates back to the 1940s when Hungarian-British physicist Dennis Gabor first proposed the idea. However, it wasn’t until the 1960s that the technology advanced enough to create practical holographic images. Since then, holography has become widely used in various industries, including entertainment, art, and security.

What is OPP Film and How is it Made?

OPP Film, or oriented polypropylene film, is a type of plastic film that is widely used in packaging and labeling applications. It is made from polypropylene resin, which is melted and then extruded through a die to form a thin film. The film is then stretched in both the machine direction and transverse direction to orient the molecules and improve its strength and clarity.

The manufacturing process of OPP Film involves several steps. First, the polypropylene resin is melted and extruded through a flat die to form a continuous sheet of molten plastic. The sheet is then cooled and solidified on a chill roll before being stretched in both directions using a series of rollers. This stretching process aligns the molecules in the film, improving its mechanical properties. Finally, the film is wound into rolls for further processing or use.

What Makes Holographic OPP Film Different?

Holographic OPP Film differs from regular OPP Film in several ways. Firstly, it has a holographic layer that gives it a unique three-dimensional appearance. This holographic layer is created by embossing the film with a pattern of microscopic grooves, which diffract light and create the holographic effect. Regular OPP Film, on the other hand, does not have this holographic layer and has a plain, smooth surface.

In addition to its holographic appearance, holographic OPP Film also has other characteristics that set it apart. It has excellent clarity and transparency, allowing for high-quality printing and visibility of the packaged product. It is also highly resistant to moisture, chemicals, and punctures, making it ideal for packaging applications. Furthermore, holographic OPP Film has good heat-sealing properties, enabling it to be easily sealed to create a secure package.

The Science Behind Holographic Imaging

| Topic | Description |

|---|---|

| Holography | A technique that allows the light scattered from an object to be recorded and later reconstructed to form a three-dimensional image. |

| Interference | The interaction of two or more waves that results in a new wave pattern. |

| Coherence | The property of light that allows it to interfere with itself and produce a stable interference pattern. |

| Diffraction | The bending of light waves around an object or through a small opening, resulting in a pattern of light and dark areas. |

| Phase | The position of a point in a wave cycle, measured in degrees or radians. |

| Reconstruction | The process of using interference patterns to recreate a three-dimensional image of an object. |

Holography is a technique that allows the recording and reconstruction of three-dimensional images. It is based on the principle of interference, where two or more light waves combine to create a new wave pattern. In holography, a laser beam is split into two parts: the object beam and the reference beam.

The object beam is directed onto the object being recorded, while the reference beam is directed onto a photographic plate or film. When the two beams meet at the recording medium, they interfere with each other and create an interference pattern. This pattern contains information about the shape and structure of the object.

To view a hologram, a laser beam is shone onto the holographic film or plate, causing it to diffract light and recreate the original wavefronts recorded during the recording process. This creates a three-dimensional image that appears to float in space. The viewer can move around and see different perspectives of the object, just as they would with a real object.

Applications of Holographic OPP Film

Holographic OPP Film has a wide range of applications in various industries. In the packaging industry, it is used to enhance the visual appeal of products and attract consumers’ attention. The holographic effect creates a sense of depth and movement, making the packaging stand out on store shelves. It is also used for labeling and branding purposes, allowing companies to create unique and eye-catching designs.

In addition to packaging and branding, holographic OPP Film is also used for security and authentication purposes. The holographic layer creates a visually striking pattern that is difficult to replicate, making it an effective tool for preventing counterfeiting. It is commonly used on banknotes, identification cards, and other high-security documents.

Advantages of Using Holographic OPP Film

There are several advantages to using holographic OPP Film in various applications. Firstly, its aesthetic appeal makes it an excellent choice for packaging and branding. The holographic effect creates a visually stunning appearance that captures consumers’ attention and enhances the perceived value of the product. It can be customized with different patterns and colors to create unique designs that reflect the brand’s identity.

Furthermore, holographic OPP Film offers excellent durability and protection. It is resistant to moisture, chemicals, and punctures, ensuring that the packaged product remains in good condition during storage and transportation. It also provides a barrier against UV radiation, which can cause damage to sensitive products. Additionally, holographic OPP Film has good heat-sealing properties, allowing for easy and secure sealing of packages.

Another significant advantage of holographic OPP Film is its anti-counterfeiting properties. The holographic layer creates a complex pattern that is difficult to replicate accurately. This makes it an effective tool for preventing counterfeiting and protecting valuable products or documents. The unique holographic design serves as a visual authentication feature that can be easily recognized by consumers or security personnel.

How to Choose the Right Holographic OPP Film for Your Needs

When selecting holographic OPP Film for your specific needs, there are several factors to consider. Firstly, you should consider the application or purpose of the film. Different holographic patterns and designs may be more suitable for specific industries or products. For example, a bold and vibrant holographic design may be ideal for a food product, while a more subtle and sophisticated design may be better suited for luxury goods.

Another important factor to consider is the desired level of security and authentication. Some holographic films offer advanced security features, such as hidden images or microtext, which can only be seen under specific lighting conditions. If security is a primary concern, you should choose a holographic film that offers these additional security features.

Additionally, you should consider the compatibility of the holographic OPP Film with your existing packaging or printing processes. Some holographic films may require specific printing techniques or equipment to achieve the desired visual effects. It is essential to ensure that the film can be easily integrated into your production process without any significant modifications or additional costs.

Manufacturing and Production of Holographic OPP Film

The production of holographic OPP Film involves several steps to ensure its quality and performance. The process begins with the selection of high-quality polypropylene resin, which is then melted and extruded through a flat die to form a continuous sheet of molten plastic. The sheet is cooled and solidified on a chill roll before being stretched in both the machine direction and transverse direction.

After stretching, the film is coated with a layer of adhesive, which acts as a bonding agent for the holographic layer. The holographic layer is created by embossing the film with a pattern of microscopic grooves using a specialized roller or cylinder. This embossing process diffracts light and creates the holographic effect.

Once the holographic layer is applied, the film goes through additional processing steps, such as corona treatment or primer coating, to improve its printability and adhesion properties. Finally, the film is wound into rolls for further processing or use.

Throughout the manufacturing process, strict quality control measures are implemented to ensure the consistency and performance of the holographic OPP Film. This includes regular testing of the film’s mechanical properties, such as tensile strength and elongation, as well as visual inspection for any defects or imperfections.

Sustainability and Environmental Impact of Holographic OPP Film

As with any plastic-based product, there are environmental concerns associated with holographic OPP Film. Polypropylene, the main material used in the film, is derived from fossil fuels and is not biodegradable. This means that if holographic OPP Film is not properly managed at the end of its life cycle, it can contribute to plastic waste and pollution.

However, efforts are being made to reduce the environmental impact of holographic OPP Film. One approach is to promote recycling and reuse of the film. Polypropylene can be recycled into new products, reducing the need for virgin materials and minimizing waste. Additionally, some manufacturers are exploring alternative materials, such as bio-based or compostable films, to create more sustainable holographic solutions.

Furthermore, advancements in manufacturing processes have led to improvements in energy efficiency and resource utilization. By optimizing production techniques and reducing waste, manufacturers can minimize their environmental footprint. Additionally, some companies are implementing eco-friendly practices, such as using renewable energy sources or implementing water conservation measures, to further reduce their impact on the environment.

Future of Holographic OPP Film in Packaging and Branding

The future of holographic OPP Film in packaging and branding looks promising, with several emerging trends and innovations on the horizon. One trend is the integration of augmented reality (AR) technology with holographic packaging. This allows consumers to interact with holographic images using their smartphones or other devices, creating a more immersive and engaging experience.

Another area of innovation is the development of smart packaging solutions using holographic OPP Film. These smart packages can incorporate sensors or indicators that provide real-time information about the product, such as temperature, freshness, or authenticity. This not only enhances the functionality of the packaging but also provides valuable data for supply chain management and consumer insights.

Furthermore, advancements in printing and manufacturing technologies are enabling the creation of more intricate and detailed holographic designs. This opens up new possibilities for creative packaging and branding solutions, allowing companies to differentiate themselves in a competitive market.

Overall, the potential for growth and expansion of holographic OPP Film in packaging and branding is significant. As consumers continue to seek unique and visually appealing products, holographic packaging offers a compelling solution that captures attention and enhances the overall brand experience.

The Versatility and Potential of Holographic OPP Film

In conclusion, holographic OPP Film is a versatile and visually striking material that has a wide range of applications in various industries. Its holographic effect creates a three-dimensional appearance that enhances the visual appeal of products and packaging. It offers excellent durability, protection, and anti-counterfeiting properties, making it an ideal choice for branding, security, and authentication purposes.

When choosing holographic OPP Film, it is essential to consider factors such as the desired holographic design, level of security, and compatibility with existing processes. Manufacturers employ strict quality control measures to ensure the consistency and performance of the film throughout the production process.

While there are environmental concerns associated with holographic OPP Film, efforts are being made to reduce its environmental impact through recycling and the development of more sustainable alternatives. The future of holographic OPP Film looks promising, with emerging trends such as augmented reality integration and smart packaging solutions driving innovation in the industry.

Overall, holographic OPP Film offers a unique combination of aesthetics, functionality, and security, making it a valuable tool for enhancing packaging, branding, and security in various industries. Its versatility and potential make it an exciting material to watch as it continues to evolve and shape the future of visual communication.

FAQs

What is holographic OPP film?

Holographic OPP film is a type of packaging material that is made from oriented polypropylene (OPP) and has a holographic design on its surface. It is commonly used for packaging products such as food, cosmetics, and electronics.

How is holographic OPP film made?

Holographic OPP film is made by coating a layer of holographic material onto a base layer of OPP film. The holographic material is created by using a laser to etch a pattern onto a metal plate, which is then transferred onto the OPP film using a process called hot stamping.

What are the benefits of using holographic OPP film?

Holographic OPP film provides several benefits, including enhanced visual appeal, increased product shelf life, and improved tamper resistance. It also offers good barrier properties against moisture, oxygen, and other contaminants.

What types of products can be packaged using holographic OPP film?

Holographic OPP film can be used to package a wide range of products, including food items such as snacks, confectionery, and beverages, as well as non-food items such as cosmetics, electronics, and pharmaceuticals.

Is holographic OPP film environmentally friendly?

Holographic OPP film is not considered to be environmentally friendly as it is made from plastic and is not biodegradable. However, some manufacturers are working to develop more sustainable alternatives to traditional OPP film.

Why choose us

Importing from us, a Chinese metalized film factory, provides cost-effective solutions, access to advanced technology, a wide range of customization options, and reliable production capabilities, ensuring high-quality products at competitive prices.

High-quality, durable films for reliability and performance

Customization options offered to meet unique project requirements.

Competitive pricing ensures cost-effectiveness for customers.

Responsive customer service for a seamless experience and satisfaction.