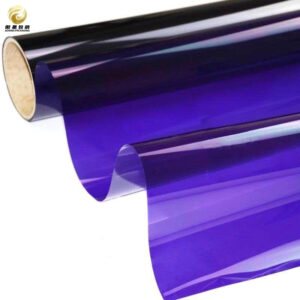

Transparent OPP Film

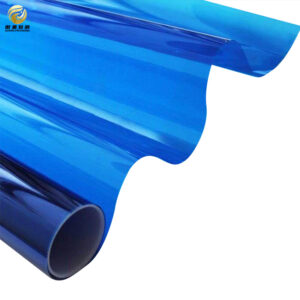

More colors and options available

About Transparent OPP Film

Transparent OPP film, also known as oriented polypropylene film, is a versatile material widely used in the packaging industry. It is a type of plastic film that is transparent, flexible, and has excellent clarity. This film is made from polypropylene, a thermoplastic polymer that is known for its high strength and durability. Transparent OPP film plays a crucial role in packaging as it provides protection, enhances product visibility, and extends the shelf life of various goods.

Understanding the Properties of Transparent OPP Film

1. Physical properties: Transparent OPP film has excellent optical properties, such as high transparency and glossiness. It also has good dimensional stability, meaning it does not shrink or stretch easily. Additionally, it has low moisture absorption and is resistant to chemicals and oils.

2. Chemical properties: Transparent OPP film is resistant to most chemicals, making it suitable for packaging products that come into contact with various substances. It also has good resistance to UV radiation, which helps protect the packaged goods from degradation caused by sunlight exposure.

3. Mechanical properties: Transparent OPP film has high tensile strength, tear resistance, and puncture resistance. These properties make it ideal for packaging products that require protection from external forces during transportation and handling.

Benefits of Using Transparent OPP Film

1. Cost-effectiveness: Transparent OPP film is an affordable packaging solution compared to other materials like glass or aluminum. It offers excellent value for money without compromising on quality or performance.

2. Durability: The mechanical properties of transparent OPP film make it highly durable, ensuring that the packaged products remain intact and protected throughout the supply chain.

3. Versatility: Transparent OPP film can be used for a wide range of applications due to its flexibility and compatibility with different packaging formats. It can be easily converted into bags, pouches, labels, or wraps to suit specific product requirements.

4. Transparency: The high transparency of transparent OPP film allows consumers to see the product inside the packaging, enhancing its visual appeal and creating a sense of trust. This is particularly important for products where visual inspection is crucial, such as food or pharmaceuticals.

Applications of Transparent OPP Film in Packaging Industry

| Application | Description |

|---|---|

| Food Packaging | Transparent OPP film is used to package food products such as snacks, confectionery, and bakery items. |

| Pharmaceutical Packaging | OPP film is used to package pharmaceutical products such as tablets, capsules, and powders. |

| Cosmetic Packaging | OPP film is used to package cosmetic products such as creams, lotions, and shampoos. |

| Electronic Packaging | OPP film is used to package electronic products such as mobile phones, tablets, and laptops. |

| Industrial Packaging | OPP film is used to package industrial products such as chemicals, lubricants, and adhesives. |

1. Food packaging: Transparent OPP film is extensively used in food packaging due to its excellent barrier properties, which help preserve the freshness and quality of the packaged food. It is commonly used for wrapping snacks, confectionery, bakery products, and frozen foods.

2. Pharmaceutical packaging: Transparent OPP film is widely used in pharmaceutical packaging as it provides a reliable barrier against moisture, light, and oxygen. It ensures the integrity and stability of pharmaceutical products, protecting them from degradation.

3. Personal care packaging: Transparent OPP film is commonly used in personal care products such as soaps, shampoos, and cosmetics. Its transparency allows consumers to see the product inside, while its barrier properties protect the contents from external factors.

4. Industrial packaging: Transparent OPP film is also used in industrial packaging for products such as electronics, automotive parts, and textiles. Its durability and protective properties ensure that these goods are safely transported and stored.

How Transparent OPP Film is Manufactured

1. Extrusion process: The manufacturing of transparent OPP film begins with the extrusion process. Polypropylene pellets are melted and extruded through a flat die to form a continuous sheet of molten polymer. This sheet is then cooled and solidified to form a thin film.

2. Coating process: In some cases, transparent OPP film may undergo a coating process to enhance its properties. This involves applying a thin layer of coating material onto one or both sides of the film to improve its barrier properties or add specific functionalities.

3. Lamination process: Transparent OPP film can also be laminated with other materials to create composite structures with enhanced properties. Lamination involves bonding the OPP film with other films or substrates using heat and pressure, resulting in a multi-layered packaging material.

Factors to Consider When Choosing Transparent OPP Film

1. Thickness: The thickness of transparent OPP film can vary depending on the application. Thicker films provide better protection and durability, while thinner films offer cost savings and flexibility.

2. Clarity: The clarity of transparent OPP film is an important consideration, especially for products where visibility is crucial. High clarity films ensure that the product inside is clearly visible, enhancing its marketability.

3. Barrier properties: Different products require different levels of barrier protection. Transparent OPP films with enhanced barrier properties, such as high oxygen or moisture barrier, are suitable for products that are sensitive to these factors.

4. Printability: Transparent OPP film can be printed with various designs, logos, or product information. The printability of the film is an important factor to consider when branding or labeling the packaged products.

Advancements in Transparent OPP Film Technology

1. Nanotechnology: Nanotechnology has been applied to transparent OPP film to enhance its properties further. Nanocomposites, which incorporate nanoparticles into the film matrix, can improve barrier properties, mechanical strength, and even add antimicrobial properties.

2. Biodegradable OPP Film: With increasing environmental concerns, biodegradable transparent OPP films have been developed. These films are made from biodegradable polymers that break down naturally over time, reducing their impact on the environment.

3. Metallized OPP Film: Metallized transparent OPP film has a thin layer of metal deposited onto its surface, providing enhanced barrier properties against light, moisture, and oxygen. This type of film is commonly used for packaging products that require extended shelf life.

Environmental Impact of Transparent OPP Film

1. Recycling options: Transparent OPP film can be recycled through various recycling programs or facilities that accept plastic films. Recycling helps reduce the amount of waste sent to landfills and conserves resources.

2. Biodegradability: Biodegradable transparent OPP films offer an environmentally friendly alternative to traditional films. These films break down naturally into harmless substances, reducing their impact on ecosystems.

3. Sustainability: Transparent OPP film manufacturers are increasingly adopting sustainable practices, such as using renewable energy sources, reducing water consumption, and implementing recycling programs. These initiatives aim to minimize the environmental footprint of film production.

Challenges Faced in the Production of Transparent OPP Film

1. Raw material availability: The availability and cost of raw materials, such as polypropylene, can impact the production of transparent OPP film. Fluctuations in raw material prices or shortages can pose challenges for manufacturers.

2. Energy consumption: The production of transparent OPP film requires significant energy input, particularly during the extrusion process. Manufacturers are continuously exploring ways to reduce energy consumption and improve energy efficiency.

3. Waste management: Waste generated during the production of transparent OPP film, such as trimmings or rejected rolls, needs to be properly managed. Recycling and waste reduction initiatives are crucial to minimize the environmental impact of film production.

Future of Transparent OPP Film in the Packaging Industry

1. Market trends: The demand for transparent OPP film is expected to grow in the coming years due to increasing consumer preference for transparent packaging and the growth of e-commerce. The rise in online shopping has created a need for protective and visually appealing packaging solutions.

2. Technological advancements: Ongoing research and development efforts are focused on improving the properties of transparent OPP film, such as barrier properties, printability, and sustainability. Advancements in nanotechnology and biodegradable films are expected to drive innovation in this field.

3. Sustainability initiatives: As sustainability becomes a key focus in the packaging industry, transparent OPP film manufacturers are likely to invest in more sustainable practices and materials. This includes the development of biodegradable films, the use of renewable energy sources, and the implementation of recycling programs.

The Role of Transparent OPP Film in Modern Packaging Solutions

In conclusion, transparent OPP film plays a vital role in the packaging industry due to its excellent properties and versatility. It provides cost-effective and durable packaging solutions for a wide range of products, including food, pharmaceuticals, personal care items, and industrial goods. The transparency of the film enhances product visibility and consumer trust. As technology advances, transparent OPP film continues to evolve with the introduction of nanotechnology, biodegradable options, and metallized films. The industry is also focusing on sustainability initiatives to reduce its environmental impact. With market trends favoring transparent packaging and increasing consumer demand for sustainable solutions, the future of transparent OPP film looks promising as it continues to meet the evolving needs of the packaging industry.

FAQs

What is transparent OPP film?

Transparent OPP film is a type of plastic film made from oriented polypropylene (OPP) that is transparent and has a high tensile strength. It is commonly used for packaging food, cosmetics, and other consumer goods.

What are the benefits of using transparent OPP film?

Transparent OPP film offers several benefits, including excellent clarity, high gloss, and good barrier properties against moisture, oxygen, and other gases. It is also lightweight, flexible, and easy to handle, making it an ideal choice for packaging applications.

What are the different types of transparent OPP film?

There are several types of transparent OPP film available, including plain OPP film, metallized OPP film, and coated OPP film. Plain OPP film is a clear film with no additional coatings or treatments. Metallized OPP film has a thin layer of metal deposited on one side to provide additional barrier properties. Coated OPP film has a coating applied to one or both sides to improve its performance in specific applications.

What are the applications of transparent OPP film?

Transparent OPP film is used in a wide range of applications, including food packaging, cosmetic packaging, gift wrapping, and label printing. It is also used in the production of adhesive tapes, book covers, and other stationery items.

Is transparent OPP film recyclable?

Yes, transparent OPP film is recyclable. However, it is important to check with your local recycling facility to determine if they accept this type of plastic film. Some facilities may require that the film be clean and free of any food or other contaminants before it can be recycled.

Why choose us

Importing from us, a Chinese metalized film factory, provides cost-effective solutions, access to advanced technology, a wide range of customization options, and reliable production capabilities, ensuring high-quality products at competitive prices.

High-quality, durable films for reliability and performance

Customization options offered to meet unique project requirements.

Competitive pricing ensures cost-effectiveness for customers.

Responsive customer service for a seamless experience and satisfaction.