PET FILMS

-

3D PET Film

-

Brushed Polyester Film

-

Brushed Surface PET Film

-

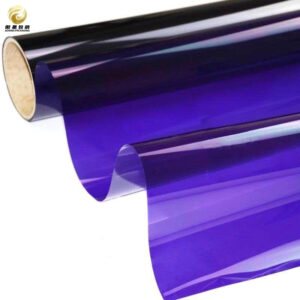

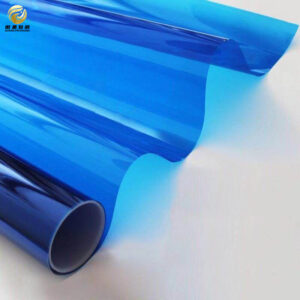

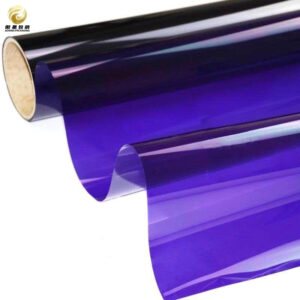

Clear Plastic Film

-

Clear Polyester Film

-

Gloss Coated PET

-

Glossy Polyester Film

-

Glossy Surface PET Film

-

High Clarity PET Film

-

Hologram PET Film

-

Holographic Lamination Film

-

Holographic Polyester Film

-

Low-Gloss PET Film

-

Matte Finish Polyester Film

-

Matte Polyester Film

-

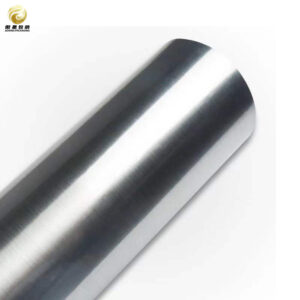

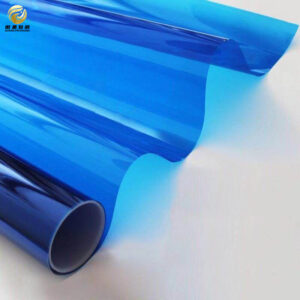

Metalized film roll

More colors and options available

About PET Films

PET films, also known as polyethylene terephthalate films, are a type of plastic film that is widely used in various industries due to their exceptional properties and versatility. These films are made from a polymer called polyethylene terephthalate, which is derived from petroleum. PET films have gained popularity over the years due to their excellent physical, chemical, and thermal properties.

The history of PET films dates back to the 1940s when they were first developed by British chemists John Rex Whinfield and James Tennant Dickson. Initially, PET films were used primarily for photographic purposes. However, with advancements in technology and manufacturing processes, their applications expanded to various industries such as packaging, electrical, medical, and solar.

Properties of PET Films

PET films possess a range of properties that make them highly desirable for numerous applications. In terms of physical properties, PET films are transparent, allowing for excellent visibility of the contents within packaging materials. Additionally, they are flexible and can be easily molded into different shapes and sizes. Despite their flexibility, PET films are also known for their strength and durability.

Chemically, PET films exhibit remarkable resistance to moisture, chemicals, and UV light. This makes them ideal for applications where protection against these elements is crucial. Moreover, PET films have excellent thermal properties. They have a high melting point and can withstand high temperatures without deforming or losing their structural integrity.

Manufacturing Process of Polyester Films

The production of PET(polyester) films involves several steps and the use of specific raw materials. The primary raw material used in the production of PET films is polyethylene terephthalate resin pellets. These pellets are melted down through a process called extrusion, where they are heated and forced through a die to form a continuous sheet of molten plastic.

After extrusion, the molten plastic is stretched in both the machine and transverse directions to orient the polymer chains and enhance the film’s mechanical properties. This stretching process is known as biaxial stretching. Following stretching, the film is annealed to relieve internal stresses and improve its dimensional stability.

Applications of PET Films

| PET Films | |

|---|---|

| Application | Metric |

| Food Packaging | Barrier Properties |

| Electronics | Dielectric Strength |

| Solar Panels | Transparency |

| Medical Equipment | Biocompatibility |

| Labels and Decals | Printability |

PET films find extensive applications in various industries due to their exceptional properties. In the packaging industry, PET films are commonly used for food packaging, pharmaceutical packaging, and other consumer goods. Their transparency allows consumers to see the product inside, while their resistance to moisture and chemicals ensures the integrity and safety of the packaged items.

In the electrical industry, PET films are widely used for insulation purposes in electrical cables and wires. They provide excellent electrical insulation properties, ensuring the safety and efficiency of electrical systems. PET films are also used in capacitors, where their high dielectric strength and low dielectric loss make them ideal for energy storage applications.

The medical industry also benefits from the use of PET films. These films are used for medical packaging, such as blister packs for medications, as they provide a barrier against moisture, gases, and contaminants. Additionally, PET films are used in surgical instruments due to their strength, flexibility, and resistance to sterilization processes.

PET films have also found applications in the solar industry. They are used as back sheets in solar panels due to their excellent weather resistance and durability. These films protect the solar cells from environmental factors such as moisture and UV radiation while maintaining high light transmission.

Advantages of PET Films

PET films offer several advantages that contribute to their widespread use in various industries. Firstly, they are cost-effective compared to other materials such as glass or metal. PET films are lightweight, which reduces transportation costs and energy consumption during production.

Furthermore, PET films are recyclable, making them an environmentally friendly choice. They can be easily recycled into new products or used as a raw material for other plastic applications. This recyclability helps reduce waste and conserve resources.

PET films are also highly versatile, as they can be customized to meet specific requirements. They can be coated or laminated with other materials to enhance their properties, such as adding barrier properties or improving printability. This versatility allows PET films to be tailored for a wide range of applications.

PET Films vs. Other Plastic Films

When comparing PET films with other plastic films such as PVC, PE, and PP films, PET films offer several advantages. PVC films are known for their flexibility and transparency, but they have poor resistance to UV light and chemicals compared to PET films. PE films, on the other hand, have excellent moisture resistance but lack the strength and thermal stability of PET films. PP films have good chemical resistance but are less transparent than PET films.

PET films excel in terms of their combination of properties, including transparency, flexibility, strength, chemical resistance, and thermal stability. However, it is important to note that each type of plastic film has its own advantages and disadvantages depending on the specific application requirements.

PET Films in Packaging Industry

PET films play a crucial role in the packaging industry due to their exceptional properties. There are different types of PET films used in packaging, including clear films for transparent packaging and metallized films for enhanced barrier properties. These films provide excellent protection against moisture, gases, and contaminants, ensuring the quality and safety of the packaged products.

The benefits of using PET films in packaging are numerous. Firstly, their transparency allows consumers to see the product inside, which can enhance the visual appeal and marketability of the packaged items. Additionally, PET films provide a strong barrier against moisture and oxygen, extending the shelf life of perishable goods.

PET films are also compatible with various printing techniques, allowing for attractive and informative packaging designs. They can be easily printed with high-quality graphics and text, enhancing brand visibility and consumer engagement. Moreover, PET films are easy to handle and can be easily converted into different packaging formats, such as pouches, trays, or labels.

PET Films in Electrical Industry

The electrical industry relies on PET films for various applications, primarily for insulation purposes. PET films are used as insulation materials in electrical cables and wires due to their excellent electrical properties. They provide high dielectric strength, which prevents electrical current from leaking or short-circuiting.

PET films also offer low dielectric loss, meaning they do not absorb much electrical energy and do not generate excessive heat. This property is crucial for maintaining the efficiency and safety of electrical systems. Additionally, PET films have good thermal stability, allowing them to withstand high temperatures without degrading or losing their insulating properties.

The benefits of using PET films in electrical applications extend beyond insulation. These films are lightweight, which reduces the weight of electrical components and facilitates easier installation. Furthermore, PET films are resistant to moisture and chemicals, protecting the electrical systems from environmental factors that could compromise their performance.

PET Films in Medical Industry

In the medical industry, PET films find extensive use in various applications due to their exceptional properties. PET films are commonly used for medical packaging, such as blister packs for medications. These films provide a barrier against moisture, gases, and contaminants, ensuring the integrity and safety of the packaged medications.

PET films are also used in surgical instruments due to their strength, flexibility, and resistance to sterilization processes. These films can withstand repeated sterilization cycles without degrading or losing their properties. Additionally, PET films can be easily molded into different shapes and sizes, allowing for the production of customized surgical instruments.

The use of PET films in the medical industry helps maintain the sterility and safety of medical devices and instruments. Their resistance to moisture and chemicals prevents contamination and ensures the effectiveness of medical procedures. Moreover, PET films are transparent, allowing healthcare professionals to easily visualize the contents and monitor any changes or damages.

PET Films in Solar Industry

The solar industry relies on PET films for their exceptional properties and durability. PET films are used as back sheets in solar panels, providing protection to the solar cells. These films offer excellent weather resistance, protecting the solar cells from moisture, UV radiation, and other environmental factors.

PET films used in solar panels are typically laminated with other materials to enhance their properties. For example, a layer of ethylene vinyl acetate (EVA) is often added to improve adhesion and provide additional protection against moisture. The use of PET films in solar panels contributes to their longevity and efficiency.

The benefits of using PET films in solar panels are significant. Firstly, these films are lightweight, reducing the weight of the solar panels and facilitating easier installation. Additionally, PET films have excellent transparency, allowing maximum light transmission to the solar cells. This enhances the overall efficiency of the solar panels and increases energy generation.

Future of PET Films

The future of PET films looks promising, with emerging trends in technology and increasing demand across various industries. One emerging trend is the development of bio-based PET films, which are made from renewable sources such as plant-based materials. These bio-based PET films offer similar properties to traditional PET films while reducing reliance on fossil fuels.

Another trend is the development of functionalized PET films with enhanced properties. For example, antimicrobial coatings can be applied to PET films used in medical applications to prevent bacterial growth and improve hygiene. Similarly, barrier coatings can be added to PET films used in packaging to enhance their resistance to moisture, oxygen, and other gases.

The potential for growth in the PET film market is significant due to the increasing demand for sustainable and environmentally friendly materials. The versatility and exceptional properties of PET films make them an attractive choice for various industries seeking cost-effective and high-performance solutions.

In conclusion, PET films have become indispensable in various industries due to their exceptional properties and versatility. These films offer a range of physical, chemical, and thermal properties that make them highly desirable for applications in packaging, electrical, medical, and solar industries. PET films provide transparency, flexibility, strength, resistance to moisture, chemicals, and UV light, making them suitable for a wide range of applications.

PET films offer several advantages over other plastic films, including cost-effectiveness, lightweight, recyclability, and versatility. They can be customized to meet specific requirements and are compatible with various printing techniques. PET films find extensive use in the packaging industry for food and pharmaceutical packaging, in the electrical industry for insulation purposes, in the medical industry for packaging and surgical instruments, and in the solar industry for back sheets in solar panels.

The future of PET films looks promising with emerging trends in technology and increasing demand for sustainable materials. The development of bio-based PET films and functionalized PET films with enhanced properties opens up new possibilities for their applications. The potential for growth in the PET film market is significant as industries continue to seek cost-effective and high-performance solutions. Overall, PET films have proven their importance and will continue to evolve and grow in the future.

FAQs

What are PET films?

PET films are thin, flexible sheets made from polyethylene terephthalate (PET) polymer. They are commonly used in packaging, printing, and electrical industries due to their excellent mechanical, thermal, and optical properties.

What are the properties of PET films?

PET films have high tensile strength, good dimensional stability, excellent clarity, and resistance to moisture, chemicals, and UV radiation. They are also recyclable and have a low environmental impact.

What are the applications of PET films?

PET films are used in a wide range of applications, including packaging for food, pharmaceuticals, and consumer goods, printing for labels, graphics, and overlays, and electrical insulation for cables, capacitors, and transformers.

What are the advantages of using PET films in packaging?

PET films offer several advantages in packaging, such as high barrier properties to oxygen, water, and aroma, good sealability, and excellent printability. They also provide a lightweight and cost-effective solution for packaging.

What are the types of PET films?

PET films are available in several types, such as clear, metallized, coated, and laminated films. Clear films are transparent and used for packaging and printing applications, while metallized films have a metallic appearance and used for decorative and barrier applications. Coated and laminated films have additional properties such as heat sealability, anti-fog, and anti-static.

What is the manufacturing process of PET films?

PET films are produced by extruding molten PET polymer through a flat die and then cooling and solidifying the film on a chill roll. The film is then stretched in both machine and transverse directions to improve its mechanical properties and thickness uniformity. The film can also be coated, laminated, or metallized depending on the application.

Why choose us

Importing from us, a Chinese metalized film factory, provides cost-effective solutions, access to advanced technology, a wide range of customization options, and reliable production capabilities, ensuring high-quality products at competitive prices.

High-quality, durable films for reliability and performance

Customization options offered to meet unique project requirements.

Competitive pricing ensures cost-effectiveness for customers.

Responsive customer service for a seamless experience and satisfaction.