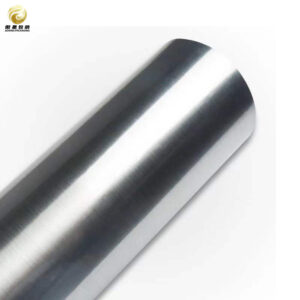

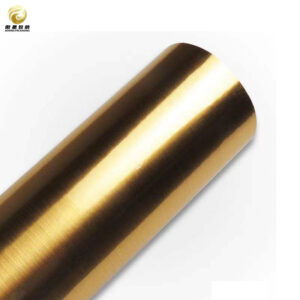

Brushed PET Film

More colors and options available

About Brushed PET Film

Brushed Pet Film is a type of film that is widely used in various industries for its unique aesthetic appeal and durability. It is made from polyethylene terephthalate (PET), a thermoplastic polymer resin that is known for its strength and versatility. The film is created by subjecting the PET material to a brushing process, which gives it a textured and brushed appearance.

The history of Brushed Pet Film dates back several decades. It was first developed in the 1960s as a way to enhance the appearance of products and provide them with a more premium look. Over the years, advancements in manufacturing technology have allowed for the production of high-quality Brushed Pet Film that meets the demands of various industries.

Understanding the Manufacturing Process of Brushed Pet Film

The manufacturing process of Brushed Pet Film involves several steps, starting with the selection of raw materials. PET resin, which is derived from petroleum, is the primary material used in the production of the film. The resin is melted and extruded into thin sheets, which are then cooled and solidified.

Once the sheets are formed, they undergo a brushing process. This involves using abrasive brushes to create a textured surface on one side of the film. The brushing process can be customized to achieve different finishes, such as matte or glossy.

After brushing, the film is coated with a protective layer to enhance its durability and resistance to scratches and other damages. The coated film is then cut into desired sizes and shapes before being packaged and shipped to customers.

Advantages of Using Brushed Pet Film

There are several advantages to using Brushed Pet Film in various industries. Firstly, it is highly scratch-resistant, making it ideal for applications where products may come into contact with abrasive surfaces or materials. This helps to prolong the lifespan of products and maintain their aesthetic appeal.

Secondly, Brushed Pet Film is known for its durability. It can withstand harsh environmental conditions, such as extreme temperatures and humidity, without losing its integrity. This makes it suitable for use in outdoor applications as well.

Furthermore, Brushed Pet Film enhances the aesthetics of products. The brushed texture adds a touch of sophistication and elegance, making products stand out from the competition. Additionally, the film can be customized with different designs and finishes to meet specific branding requirements.

In terms of cost-effectiveness, Brushed Pet Film offers a more affordable alternative to other finishing techniques such as anodizing or powder coating. It provides a similar visual effect at a fraction of the cost, making it a popular choice among manufacturers.

Lastly, Brushed Pet Film is easy to clean and maintain. It can be wiped clean with a damp cloth or mild detergent, eliminating the need for specialized cleaning products or procedures.

Applications of Brushed Pet Film in Various Industries

| Industry | Application | Metric |

|---|---|---|

| Automotive | Interior trim | Scratch resistance |

| Electronics | Touchscreens | Anti-glare properties |

| Packaging | Labels and stickers | Printability |

| Construction | Decorative laminates | UV resistance |

| Medical | X-ray film | Clarity |

Brushed Pet Film finds applications in a wide range of industries due to its versatility and aesthetic appeal. In the automotive industry, it is used for interior trims, dashboards, and door panels to give vehicles a luxurious look. The film’s scratch-resistant properties make it ideal for these applications, as they are prone to wear and tear.

In the electronics industry, Brushed Pet Film is used for the casing of electronic devices such as smartphones, laptops, and tablets. The film not only provides protection but also enhances the overall appearance of the devices.

The home appliances industry also benefits from the use of Brushed Pet Film. It is commonly used for kitchen appliances like refrigerators, ovens, and dishwashers to give them a modern and sleek look. The film’s durability ensures that these appliances can withstand daily use without losing their aesthetic appeal.

In the furniture industry, Brushed Pet Film is used for surfaces such as tabletops, cabinets, and shelves. The film adds texture and depth to the furniture, making it more visually appealing. Additionally, its scratch-resistant properties make it suitable for high-traffic areas.

Lastly, Brushed Pet Film is used in the packaging industry for product packaging and displays. It adds a premium look to packaging materials and helps products stand out on store shelves.

How Brushed Pet Film Enhances the Aesthetics of Products

One of the key reasons why Brushed Pet Film is popular in various industries is its ability to enhance the aesthetics of products. The film offers different finishes, such as matte or glossy, which can be customized to meet specific design requirements.

The brushed texture of the film adds a unique visual element to products. It creates a sense of depth and dimension, making them more visually interesting. The texture also helps to hide fingerprints and smudges, ensuring that products maintain their pristine appearance.

Moreover, Brushed Pet Film can be customized with different designs and patterns. This allows manufacturers to create unique and eye-catching products that stand out from the competition. The film can be printed with logos, graphics, or even textures that mimic natural materials like wood or metal.

In addition to its aesthetic appeal, Brushed Pet Film also provides a tactile experience for users. The textured surface adds a tactile element to products, making them more engaging and enjoyable to interact with.

Durability and Resistance of Brushed Pet Film

Brushed Pet Film is known for its durability and resistance to various environmental factors. Firstly, it is highly scratch-resistant, thanks to the brushing process that creates a textured surface. The texture helps to distribute forces evenly across the film, reducing the likelihood of scratches or damages.

Additionally, Brushed Pet Film is resistant to chemicals, making it suitable for applications where products may come into contact with corrosive substances. This resistance ensures that the film maintains its integrity and appearance even in harsh chemical environments.

Furthermore, Brushed Pet Film is UV-resistant, meaning it can withstand prolonged exposure to sunlight without fading or discoloration. This makes it suitable for outdoor applications where products may be exposed to direct sunlight.

Lastly, Brushed Pet Film is water-resistant, making it ideal for applications where products may come into contact with water or other liquids. The film’s resistance to water helps to prevent warping or damage, ensuring that products maintain their structural integrity.

Maintenance and Cleaning of Brushed Pet Film

Maintaining and cleaning Brushed Pet Film is relatively simple and straightforward. To keep the film looking its best, it is recommended to clean it regularly using a soft cloth or sponge dampened with water or a mild detergent.

When cleaning, it is important to avoid using abrasive materials or harsh chemicals that can scratch or damage the film. Instead, opt for gentle cleaning agents that are specifically designed for use on delicate surfaces.

It is also advisable to avoid using excessive force when cleaning Brushed Pet Film. Gently wipe the surface in a circular motion to remove any dirt or grime. For stubborn stains, a soft-bristled brush can be used, but caution should be exercised to prevent scratching.

Furthermore, it is important to dry the film thoroughly after cleaning to prevent water spots or streaks. Use a clean, dry cloth to remove any excess moisture from the surface.

Comparison of Brushed Pet Film with Other Finishing Techniques

When considering finishing options for products, it is important to compare Brushed Pet Film with other techniques such as anodizing, powder coating, and painting.

Anodizing is a process that involves creating an oxide layer on the surface of metal products through an electrochemical process. While anodizing provides excellent corrosion resistance and durability, it may not offer the same level of customization and aesthetic appeal as Brushed Pet Film. Additionally, anodizing is typically more expensive and time-consuming compared to applying Brushed Pet Film.

Powder coating is another popular finishing technique that involves applying a dry powder to the surface of products and then curing it with heat. While powder coating provides excellent durability and resistance to scratches, it may not offer the same level of texture and depth as Brushed Pet Film. Additionally, powder coating can be more expensive and may require specialized equipment for application.

Painting is a traditional finishing technique that involves applying liquid paint to the surface of products. While painting offers a wide range of color options, it may not provide the same level of durability and resistance to scratches as Brushed Pet Film. Additionally, painting can be time-consuming and may require multiple coats for optimal coverage.

Environmental Impact of Brushed Pet Film

In recent years, there has been an increased focus on the environmental impact of various materials and manufacturing processes. When it comes to Brushed Pet Film, there are several factors to consider in terms of sustainability and recycling options.

PET resin, which is used in the production of Brushed Pet Film, is a recyclable material. This means that the film can be recycled at the end of its life cycle, reducing waste and minimizing its environmental impact. Recycling PET resin helps to conserve natural resources and reduce greenhouse gas emissions associated with the production of new materials.

Furthermore, Brushed Pet Film is a durable material that can withstand prolonged use without losing its integrity. This means that products made with Brushed Pet Film have a longer lifespan, reducing the need for frequent replacements and minimizing waste.

It is important for manufacturers and consumers alike to prioritize recycling and proper disposal of Brushed Pet Film to ensure its environmental sustainability. By implementing recycling programs and educating consumers about the importance of recycling, the environmental impact of Brushed Pet Film can be minimized.

Future Developments in Brushed Pet Film Technology

As technology continues to advance, there are several future developments in Brushed Pet Film technology that can be expected. One area of development is the manufacturing process itself. Advancements in extrusion and brushing techniques can lead to improved efficiency and quality of the film.

Additionally, there is potential for the development of new finishes and designs for Brushed Pet Film. Manufacturers may explore different brushing patterns and textures to create unique visual effects. Furthermore, advancements in printing technology can allow for more intricate and detailed designs to be applied to the film.

Another area of development is the integration of additional functionalities into Brushed Pet Film. For example, there may be advancements in incorporating antimicrobial properties into the film, making it suitable for applications in healthcare or food industries.

Overall, the future of Brushed Pet Film technology holds exciting possibilities for enhanced aesthetics, improved functionality, and increased sustainability.

Is Brushed Pet Film the Right Choice for Your Product?

When considering whether Brushed Pet Film is the right choice for your product, there are several factors to consider. Firstly, the aesthetic appeal of the film and how it aligns with your product’s branding and target market. The brushed texture and customizable designs can help differentiate your product from competitors.

Secondly, the durability and resistance of Brushed Pet Film are important considerations. If your product is exposed to harsh environmental conditions or prone to scratches, the film’s properties can help maintain its appearance and prolong its lifespan.

Additionally, the cost-effectiveness of Brushed Pet Film compared to other finishing techniques should be taken into account. If you are looking for a more affordable option without compromising on visual appeal, Brushed Pet Film may be a suitable choice.

Lastly, the environmental impact of Brushed Pet Film should be considered. If sustainability is a priority for your brand or industry, opting for a recyclable material like Brushed Pet Film can help reduce waste and minimize environmental impact.

In conclusion, Brushed Pet Film offers a unique combination of aesthetic appeal, durability, and cost-effectiveness that makes it a popular choice in various industries. By understanding its manufacturing process, advantages, applications, and maintenance requirements, you can make an informed decision on whether Brushed Pet Film is the right choice for your product.

FAQs

What is brushed pet film?

Brushed PET film is a type of plastic film that has a brushed texture on one side. It is made from polyethylene terephthalate (PET) and is commonly used in various applications such as packaging, printing, and laminating.

What are the benefits of using brushed pet film?

Brushed PET film offers several benefits such as scratch resistance, durability, and a unique aesthetic appeal. It is also resistant to moisture, chemicals, and UV radiation, making it suitable for outdoor applications.

What are the applications of brushed pet film?

Brushed PET film is commonly used in various applications such as packaging, printing, and laminating. It is also used in the automotive industry for interior trims and in the electronics industry for touchscreens and displays.

How is brushed pet film made?

Brushed PET film is made by extruding PET resin through a die and then passing it through a series of rollers that create the brushed texture on one side of the film. The film is then cooled and wound onto a roll.

What are the different types of brushed pet film?

There are several types of brushed PET film available in the market, including clear, colored, and metallized films. The thickness of the film can also vary depending on the application.

Is brushed pet film recyclable?

Yes, brushed PET film is recyclable. It can be recycled through the same process as other PET products, which involves melting the film down and reforming it into new products.

Why choose us

Importing from us, a Chinese metalized film factory, provides cost-effective solutions, access to advanced technology, a wide range of customization options, and reliable production capabilities, ensuring high-quality products at competitive prices.

High-quality, durable films for reliability and performance

Customization options offered to meet unique project requirements.

Competitive pricing ensures cost-effectiveness for customers.

Responsive customer service for a seamless experience and satisfaction.