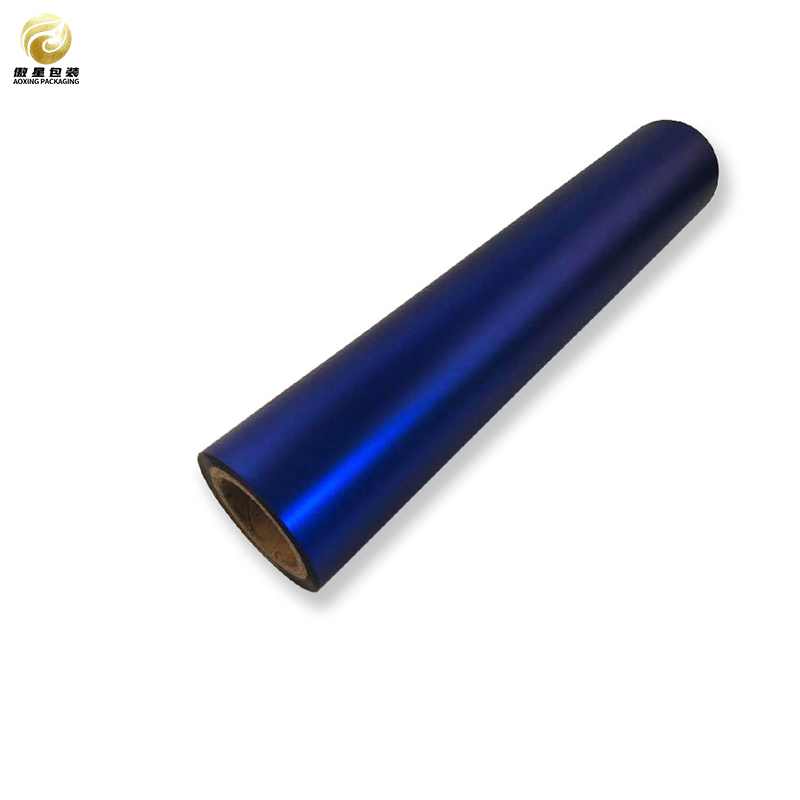

Dull Finish OPP Film

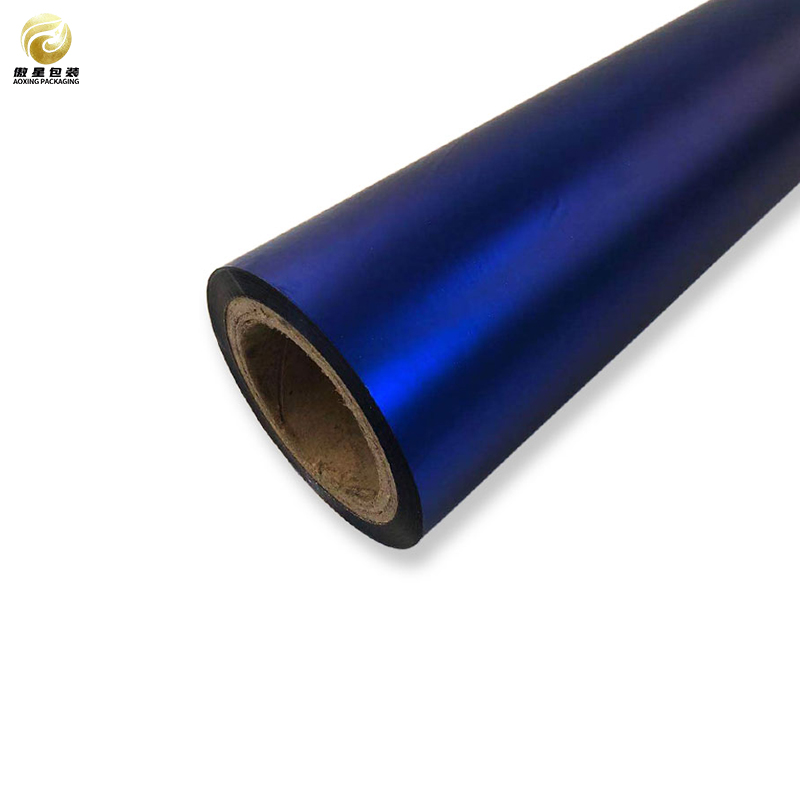

| Product | Matte OPP Film |

| Material | OPP + color+ aluminum layer / OPP + aluminum + color layer |

| Thickness | 15um;18um |

| Color Option | Red,Blue,Purple,Green,Gold,Yellow,Rose,Rainbow,etc. |

| Width & Length | Width:500~1800mm Length:Customized |

Detailed Descriptions

Product Description: Dull Finish OPP Film

Introducing our premium Dull Finish OPP (Oriented Polypropylene) Film, a versatile and high-performance packaging solution designed to meet the diverse needs of modern industries. Engineered for excellence, this film combines functionality with aesthetic appeal, making it an ideal choice for a wide range of applications, from food packaging to retail displays.

Key Features:

1. Superior Clarity and Printability: Our Dull Finish OPP Film offers exceptional clarity while maintaining a sophisticated matte appearance. This unique finish not only enhances the visual appeal of your products but also provides an excellent surface for high-quality printing. The dull texture minimizes glare, ensuring that your branding and graphics stand out prominently.

2. Enhanced Durability: Crafted from high-quality polypropylene, this film exhibits remarkable strength and durability. It is resistant to tearing, puncturing, and moisture, making it suitable for both indoor and outdoor applications. Whether you are packaging delicate items or robust products, our Dull Finish OPP Film ensures reliable protection throughout the supply chain.

3. Eco-Friendly Option: As sustainability becomes increasingly important in today’s market, our Dull Finish OPP Film stands out as an environmentally responsible choice. Made from recyclable materials, it aligns with eco-conscious practices without compromising on performance or quality.

4. Versatile Applications: This film is ideal for a variety of uses including food packaging, gift wrapping, labels, and promotional materials. Its versatility allows businesses across multiple sectors—such as food service, retail, and e-commerce—to utilize it effectively in their packaging solutions.

5. Easy to Work With: Our Dull Finish OPP Film is designed for ease of use in various manufacturing processes. It can be easily heat-sealed or laminated, allowing for seamless integration into existing production lines. Additionally, its lightweight nature contributes to reduced shipping costs and improved efficiency.

6. Customizable Options: We understand that every business has unique requirements. Therefore, we offer customizable sizes and thicknesses to cater to your specific needs. Whether you require small rolls for intricate designs or larger formats for bulk packaging, we can accommodate your requests.

Applications:

– Food Packaging: Ideal for wrapping snacks, baked goods, and other perishable items while maintaining freshness. – Retail Displays: Perfect for creating eye-catching product displays that attract consumer attention. – Labels & Stickers: Provides an excellent base for labels that require a matte finish without compromising on durability. – Gift Wrapping: Adds a touch of elegance to gift packaging with its sophisticated dull finish.

Conclusion:

As a reputable manufacturer in the industry, we understand the importance of bulk buying for businesses looking to optimize their supply chain. We offer competitive bulk prices that allow you to maximize your investment while ensuring you have an ample supply of our high-quality OPP film. Whether you are a small business or a large corporation, our wholesale options are tailored to meet your specific needs.

In addition to our standard offerings, we also provide OEM services to accommodate custom specifications. Our experienced team works closely with clients to develop tailored solutions that align with their branding and packaging requirements. This flexibility positions us as a preferred partner for businesses seeking reliable packaging solutions.

With years of experience as a prominent producer in the market, we have established strong relationships with clients worldwide. Our commitment to quality and customer satisfaction has made us a trusted name among suppliers in the industry. When you choose our Dull Finish OPP Film, you are not just purchasing a product; you are investing in a partnership that prioritizes your success.

In summary, our Dull Finish OPP Film is an exceptional choice for businesses looking for high-quality packaging solutions from a reputable manufacturer in China. With options for bulk buying at wholesale prices and OEM services available, we are well-equipped to meet your needs as an exporter committed to excellence. Contact us today to learn more about how we can support your business with our superior packaging products.