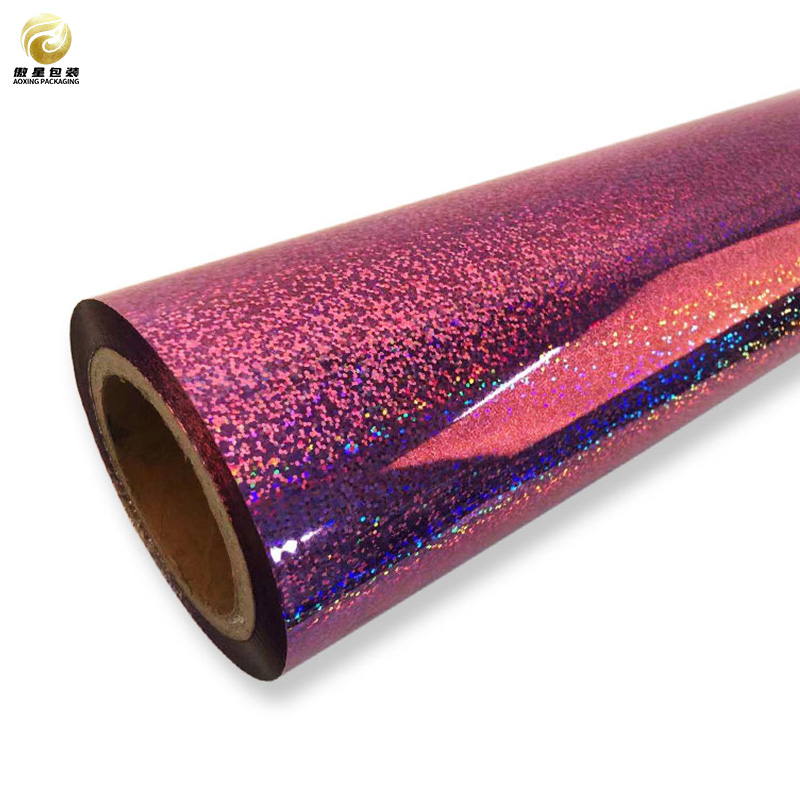

Hologram Polypropylene Film

| Product | Holographic OPP Film |

| Material | OPP + color+ aluminum layer / OPP + aluminum + color layer |

| Thickness | 15um;18um |

| Color Option | Red,Blue,Purple,Green,Gold,Yellow,Rose,Rainbow,etc. |

| Width & Length | Width:500~1800mm Length:Customized |

Detailed Descriptions

Product Description: Hologram Polypropylene Film

Elevate your packaging and branding solutions with our premium Hologram Polypropylene Film, a cutting-edge material designed to captivate and engage consumers while providing exceptional durability and versatility. This innovative film combines the unique visual appeal of holographic effects with the practical benefits of polypropylene, making it an ideal choice for a wide range of applications across various industries.

Key Features:

1. Stunning Visual Appeal: The holographic finish of our polypropylene film creates a mesmerizing play of light and color, ensuring that your products stand out on the shelves. The dynamic patterns and reflections not only enhance aesthetic appeal but also draw attention, making it an effective tool for branding and marketing.

2. Superior Durability: Crafted from high-quality polypropylene, this film offers remarkable strength and resilience. It is resistant to tearing, puncturing, and moisture, ensuring that your packaging remains intact and visually appealing throughout its lifecycle. This durability makes it suitable for both indoor and outdoor applications.

3. Versatile Applications: Our Hologram Polypropylene Film is highly adaptable, making it perfect for a variety of uses including product packaging, labels, promotional materials, gift wraps, and more. Whether you are in the food industry, cosmetics sector, or retail market, this film can be tailored to meet your specific needs.

4. Eco-Friendly Options: We understand the importance of sustainability in today’s market. Our Hologram Polypropylene Film is available in eco-friendly formulations that minimize environmental impact without compromising on quality or performance. This allows businesses to align their packaging solutions with their sustainability goals.

5. Easy to Work With: Designed for seamless integration into existing production processes, our film can be easily printed on or laminated to enhance its functionality further. Its compatibility with various printing techniques ensures that you can achieve high-quality graphics that complement the holographic effect.

6. Customizable Solutions: We offer a range of thicknesses and finishes to suit your specific requirements. Whether you need a lightweight option for cost-effective packaging or a thicker variant for added protection, our team is ready to assist you in selecting the perfect solution tailored to your project.

Applications:

– Retail Packaging: Enhance product visibility and attract customers with eye-catching holographic designs. – Labels & Stickers: Create unique labels that stand out while providing essential information about your products. – Promotional Materials: Use holographic film in brochures or flyers to create an unforgettable impression at trade shows or events. – Gift Wrapping: Add a touch of elegance and excitement to gifts with our stunning holographic wrapping options.

Conclusion:

As a prominent manufacturer in the industry, we understand the importance of flexibility and scalability. We offer bulk buy options that cater to businesses of all sizes, allowing you to take advantage of wholesale pricing without compromising on quality. Our competitive bulk price ensures that you receive the best value for your investment while maintaining the high standards your customers expect.

In addition to our standard offerings, we also provide OEM services tailored to meet your specific requirements. Whether you need custom sizes, finishes, or branding elements, our experienced team is dedicated to delivering solutions that align with your vision.

Partnering with us means choosing a reliable producer who prioritizes customer satisfaction and product excellence. Our commitment to quality control and timely delivery has established us as a preferred supplier for businesses seeking top-tier holographic films.

Explore the possibilities with our Hologram Polypropylene Film today and experience the difference that comes from working with an industry-leading exporter. Contact us for more information on how we can support your business needs through our extensive range of products and services.