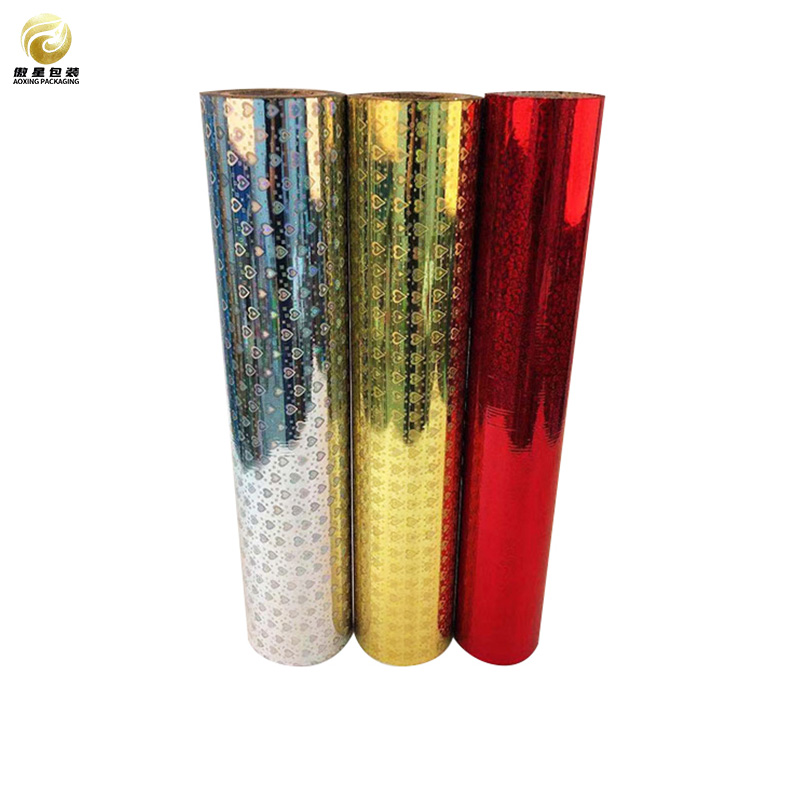

Holographic Effect OPP Film

| Product | Holographic OPP Film |

| Material | OPP + color+ aluminum layer / OPP + aluminum + color layer |

| Thickness | 15um;18um |

| Color Option | Red,Blue,Purple,Green,Gold,Yellow,Rose,Rainbow,etc. |

| Width & Length | Width:500~1800mm Length:Customized |

Detailed Descriptions

Product Description: Holographic Effect OPP Film

Elevate your packaging and creative projects with our premium Holographic Effect OPP Film, a versatile and visually stunning material designed to captivate and engage. This high-quality oriented polypropylene (OPP) film features a mesmerizing holographic finish that refracts light in a spectrum of colors, creating an eye-catching effect that is sure to leave a lasting impression.

Key Features:

1. Vibrant Holographic Finish: The unique holographic effect transforms ordinary packaging into extraordinary displays. As light interacts with the film, it produces a dynamic array of colors that shift and change, adding depth and dimension to your products.

2. Durable and Versatile: Our OPP film is engineered for durability, ensuring that it withstands the rigors of handling and transportation while maintaining its striking appearance. It is suitable for a wide range of applications, including gift wrapping, product packaging, labels, and promotional materials.

3. Eco-Friendly Composition: Committed to sustainability, our Holographic Effect OPP Film is made from recyclable materials. This eco-conscious choice allows you to enhance your branding while minimizing environmental impact.

4. Easy to Work With: The film is designed for seamless integration into various production processes. It can be easily cut, sealed, or printed on, making it an ideal choice for both small-scale projects and large-scale manufacturing runs.

5. Enhanced Visual Appeal: Whether you are looking to attract customers in retail settings or create stunning presentations for special events, the holographic effect adds an element of sophistication and allure that sets your products apart from the competition.

6. Customizable Options: We understand that every project is unique. Our Holographic Effect OPP Film can be customized in terms of thickness, size, and design to meet your specific requirements, ensuring that you achieve the perfect look for your brand.

Applications:

– Retail Packaging: Make your products stand out on the shelves with eye-catching packaging that draws attention. – Gift Wrapping: Add a touch of elegance to gifts with shimmering wrapping that enhances the overall presentation. – Labels & Stickers: Create unique labels that not only convey information but also serve as decorative elements. – Promotional Materials: Use this film for brochures, flyers, or business cards that leave a memorable impression on potential clients.

Conclusion:

Our Holographic Effect OPP Film is available for bulk buy, allowing businesses to take advantage of competitive wholesale pricing. Whether you are a small business looking to make a statement or a large corporation seeking to enhance your product presentation, our bulk price options cater to all needs. As an established exporter in the industry, we ensure that our products meet international standards while providing exceptional value.

We also offer OEM services, allowing you to customize the film according to your specific requirements. This flexibility makes our Holographic Effect OPP Film not only visually striking but also tailored to fit your brand’s identity. By choosing us as your partner, you gain access to high-quality materials that can help differentiate your products in the marketplace.

In summary, our Holographic Effect OPP Film is the perfect solution for businesses looking to enhance their packaging with a touch of elegance and flair. With our extensive experience as a producer and supplier in the industry, we are dedicated to providing you with the best products at competitive prices. Contact us today to learn more about how you can benefit from our offerings and secure your order at bulk prices!