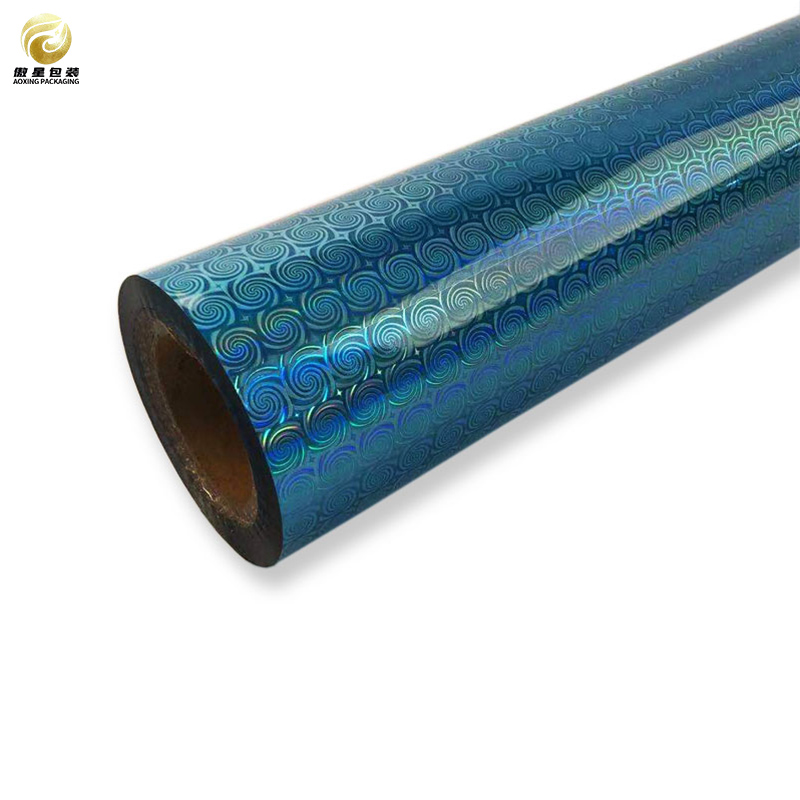

Holographic Lamination OPP Film

| Product | Holographic OPP Film |

| Material | OPP + color+ aluminum layer / OPP + aluminum + color layer |

| Thickness | 15um;18um |

| Color Option | Red,Blue,Purple,Green,Gold,Yellow,Rose,Rainbow,etc. |

| Width & Length | Width:500~1800mm Length:Customized |

Detailed Descriptions

Product Description: Holographic Lamination OPP Film

Elevate your packaging and branding with our premium Holographic Lamination OPP Film, a cutting-edge solution designed to enhance visual appeal while providing superior protection. This innovative film combines the durability of oriented polypropylene (OPP) with a stunning holographic finish, creating an eye-catching effect that captivates consumers and sets your products apart in a competitive marketplace.

Key Features:

1. Striking Visual Appeal: The holographic lamination creates a dynamic interplay of light and color, producing a mesmerizing effect that draws attention from every angle. This unique finish not only enhances the aesthetic value of your packaging but also reinforces brand identity by creating a memorable visual experience.

2. Exceptional Durability: Crafted from high-quality OPP material, our holographic lamination film offers outstanding resistance to tearing, moisture, and UV light. This ensures that your packaging remains intact and visually appealing throughout its lifecycle, whether on retail shelves or in transit.

3. Versatile Applications: Ideal for a wide range of applications, our Holographic Lamination OPP Film is perfect for product packaging, labels, promotional materials, and more. It seamlessly adheres to various substrates, making it suitable for both flexible and rigid packaging solutions.

4. Enhanced Protection: In addition to its stunning appearance, this lamination film provides an extra layer of protection against scratches and scuffs. It safeguards printed graphics and text from fading or damage, ensuring that your branding remains vibrant and intact.

5. Eco-Friendly Options Available: We understand the importance of sustainability in today’s market. Our Holographic Lamination OPP Film is available in eco-friendly options that meet industry standards for environmental responsibility without compromising on quality or performance.

6. Easy Application: Designed for efficiency, our film can be easily applied using standard lamination processes. Its compatibility with various printing techniques allows for seamless integration into your existing production workflow.

7. Customizable Solutions: We offer customizable sizes and thicknesses to meet your specific requirements. Whether you need small rolls for intricate designs or larger formats for bulk packaging, we can tailor our products to suit your needs.

Why Choose Our Holographic Lamination OPP Film?

In an era where first impressions matter more than ever, investing in high-quality packaging solutions is crucial for brand success. Our Holographic Lamination OPP Film not only enhances the visual appeal of your products but also communicates quality and innovation to consumers. By choosing our film, you are not just opting for superior aesthetics; you are also ensuring that your products are protected and presented in the best possible light.

Conclusion:

As a prominent manufacturer in the industry, we understand the importance of flexibility and customization. We offer OEM services tailored to your specific needs, allowing you to create unique packaging solutions that resonate with your target audience. Whether you are looking to bulk buy for large-scale production or seeking wholesale options for smaller quantities, we provide competitive bulk prices that cater to businesses of all sizes.

Our commitment to excellence extends beyond just product quality; we strive to build lasting partnerships with our clients. By choosing us as your preferred supplier, you gain access to a reliable source of high-quality Holographic Lamination OPP Film that can be seamlessly integrated into your production processes.

In summary, our Holographic Lamination OPP Film is an ideal choice for businesses seeking an innovative packaging solution. With our extensive experience as a producer and exporter from China, we are well-equipped to meet your demands efficiently and effectively. Contact us today to explore how our products can enhance your brand visibility and drive sales through captivating packaging solutions.