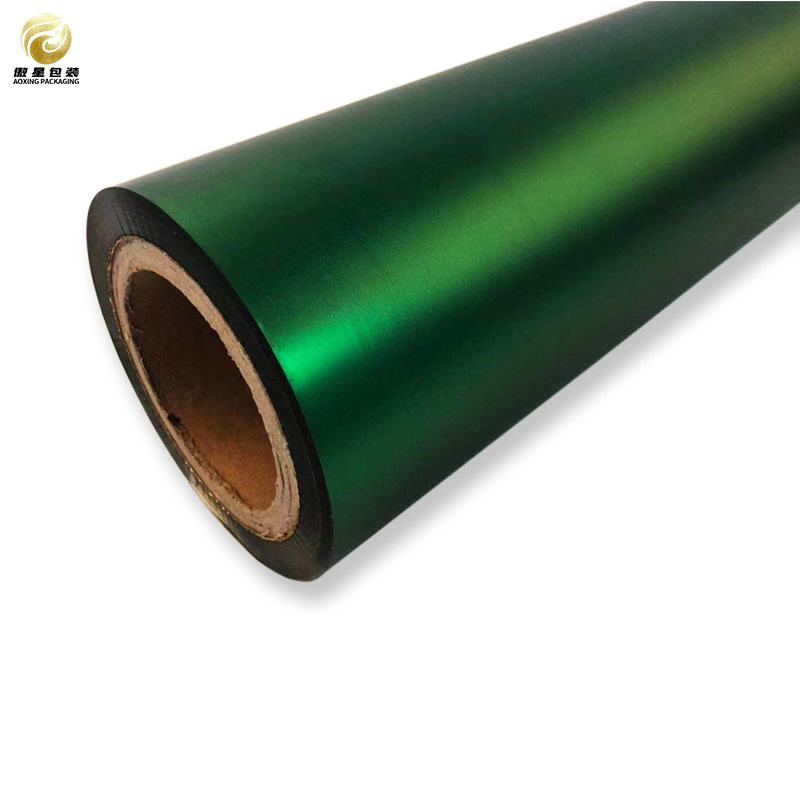

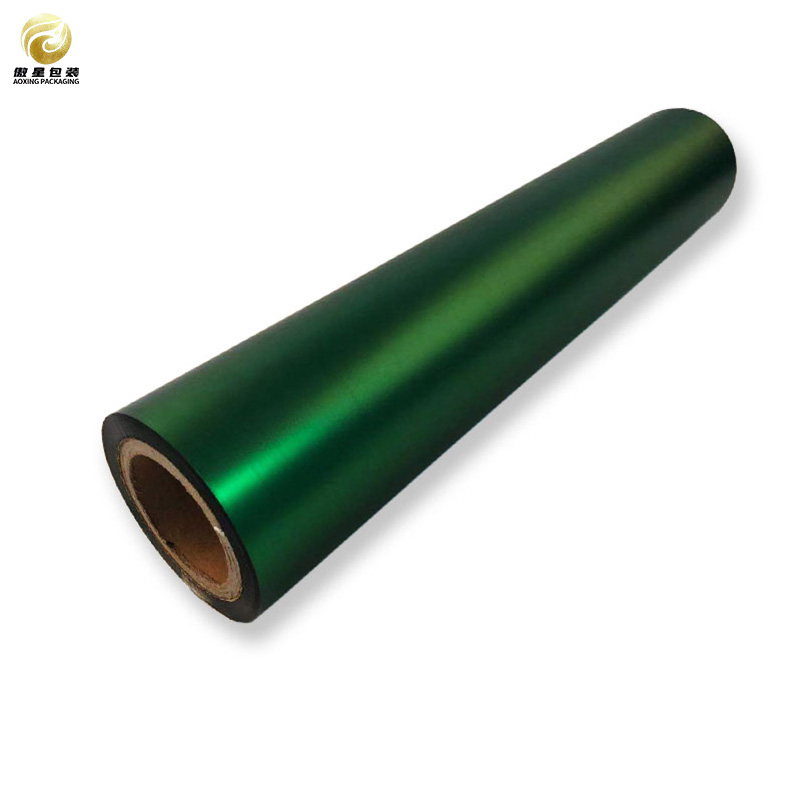

Low-Gloss OPP Film

| Product | Matte OPP Film |

| Material | OPP + color+ aluminum layer / OPP + aluminum + color layer |

| Thickness | 15um;18um |

| Color Option | Red,Blue,Purple,Green,Gold,Yellow,Rose,Rainbow,etc. |

| Width & Length | Width:500~1800mm Length:Customized |

Detailed Descriptions

Product Description: Low-Gloss OPP Film

Introducing our premium Low-Gloss OPP Film, a versatile and high-performance packaging solution designed to meet the diverse needs of modern industries. Engineered with precision and crafted from top-quality oriented polypropylene (OPP), this film offers an exceptional balance of durability, clarity, and aesthetic appeal, making it an ideal choice for a wide range of applications.

Key Features:

1. Low-Gloss Finish: The unique low-gloss surface of our OPP film provides a sophisticated matte appearance that enhances the visual appeal of your products while minimizing glare. This feature is particularly beneficial for packaging items where clarity and presentation are paramount, such as gourmet foods, cosmetics, and luxury goods.

2. Superior Clarity: Despite its low-gloss finish, our OPP film maintains excellent transparency, allowing for optimal product visibility. This ensures that your customers can appreciate the quality and details of the packaged items without any distractions.

3. Exceptional Barrier Properties: Our Low-Gloss OPP Film is engineered to provide outstanding barrier protection against moisture, oxygen, and other environmental factors. This helps extend the shelf life of perishable goods and preserves the integrity of sensitive products.

4. Lightweight Yet Durable: The lightweight nature of our OPP film does not compromise its strength. It offers excellent puncture resistance and tensile strength, making it suitable for both manual and automated packaging processes.

5. Eco-Friendly Option: As sustainability becomes increasingly important in today’s market, our Low-Gloss OPP Film stands out as an eco-friendly choice. It is fully recyclable and produced using environmentally responsible manufacturing practices.

6. Versatile Applications: This film is suitable for a wide array of applications including food packaging, retail displays, labels, and promotional materials. Its adaptability makes it an essential component for businesses looking to enhance their packaging solutions.

7. Customizable Options: We understand that every business has unique requirements. Our Low-Gloss OPP Film can be customized in terms of thickness, width, and printing options to align perfectly with your branding needs.

Applications:

– Food Packaging: Ideal for snacks, baked goods, and frozen foods where freshness is key. – Retail Packaging: Perfect for apparel, accessories, and gift items that require an elegant presentation. – Labels & Stickers: Provides a professional finish for product labels that need to stand out on shelves. – Promotional Materials: Excellent for brochures or flyers that require a touch of sophistication without excessive shine.

Conclusion:

Our Low-Gloss OPP Film is ideal for businesses looking to enhance their packaging aesthetics while ensuring durability and functionality. This film features a unique low-gloss finish that provides an elegant appearance, making it suitable for a wide range of applications, including food packaging, retail displays, and promotional materials. Its excellent clarity and strength ensure that your products are not only visually appealing but also well-protected during transit and storage.

As an exporter with extensive experience in the global market, we understand the importance of reliable supply chains. Our commitment to quality and customer satisfaction has established us as a preferred choice for businesses seeking bulk buy options. We offer competitive wholesale pricing, allowing you to maximize your profit margins while maintaining high standards for your packaging solutions.

For companies interested in customized solutions, we provide OEM services tailored to your specific requirements. Our team works closely with you to develop bespoke products that align with your brand identity and operational needs. By choosing our Low-Gloss OPP Film, you can benefit from bulk pricing that ensures cost-effectiveness without compromising on quality.

In summary, our Low-Gloss OPP Film stands out as a top-tier choice for businesses looking for reliable packaging solutions. With our expertise as a producer and supplier based in China, we are well-equipped to meet your demands efficiently. Whether you are looking to bulk buy or explore wholesale options, our competitive pricing and commitment to excellence make us the ideal partner for all your packaging needs. Contact us today to learn more about how we can support your business with our exceptional Low-Gloss OPP Film offerings.