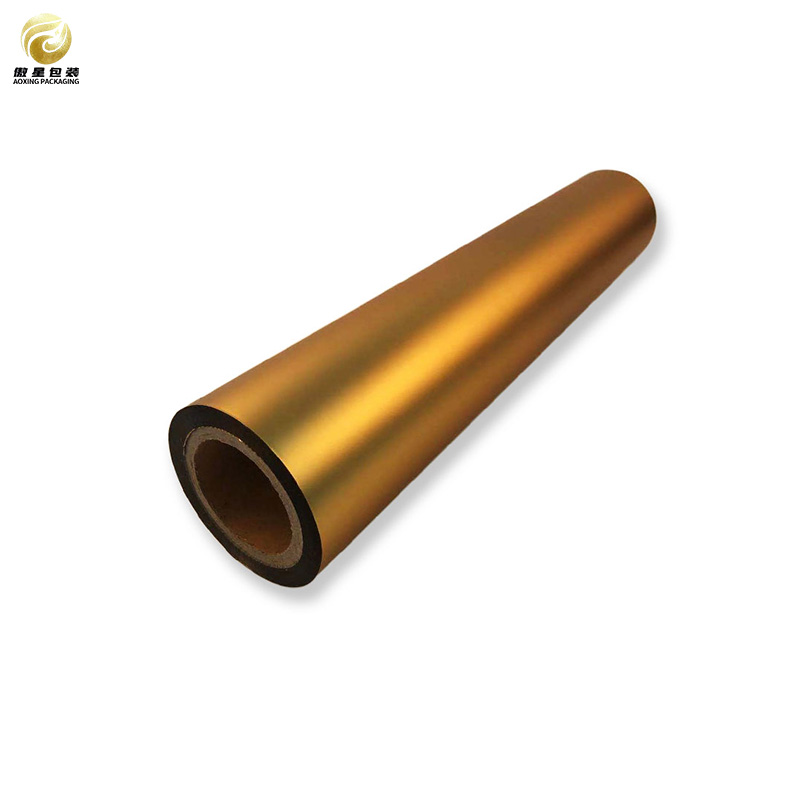

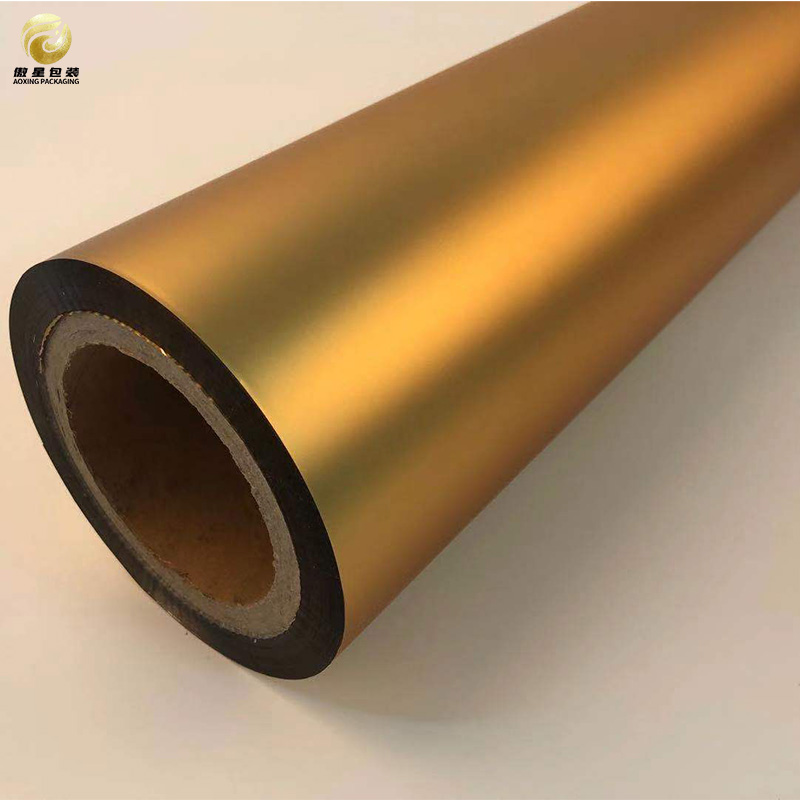

Matte Finish Polypropylene Film

| Product | Matte OPP Film |

| Material | OPP + color+ aluminum layer / OPP + aluminum + color layer |

| Thickness | 15um;18um |

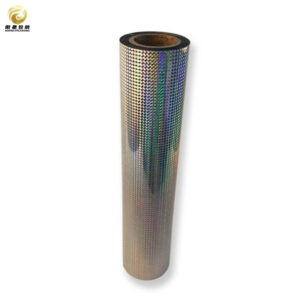

| Color Option | Red,Blue,Purple,Green,Gold,Yellow,Rose,Rainbow,etc. |

| Width & Length | Width:500~1800mm Length:Customized |

Detailed Descriptions

Product Description: Matte Finish Polypropylene Film

Introducing our premium Matte Finish Polypropylene Film, a versatile and high-performance material designed to meet the diverse needs of various industries. Engineered for excellence, this film combines durability with an elegant matte finish, making it an ideal choice for applications that require both aesthetic appeal and functional reliability.

Key Features:

1. Superior Aesthetic Quality: The matte finish of our polypropylene film provides a sophisticated look that enhances the visual appeal of printed materials. It minimizes glare and reflections, ensuring that colors remain vibrant and true to life, making it perfect for high-quality packaging, labels, and promotional materials.

2. Exceptional Durability: Crafted from high-grade polypropylene, this film exhibits remarkable resistance to tearing, puncturing, and moisture. Its robust nature ensures longevity in various environments, making it suitable for both indoor and outdoor applications.

3. Versatile Applications: Our Matte Finish Polypropylene Film is ideal for a wide range of uses including packaging for food products, cosmetics, pharmaceuticals, and consumer goods. It is also an excellent choice for creating high-end brochures, business cards, and other marketing materials that demand a touch of elegance.

4. Easy to Print On: Designed with print compatibility in mind, this film allows for excellent ink adhesion across various printing methods including flexography, lithography, and digital printing. This ensures crisp graphics and sharp text that stand out while maintaining the integrity of the matte finish.

5. Eco-Friendly Option: Our polypropylene film is recyclable and produced with environmentally conscious practices. By choosing our Matte Finish Polypropylene Film, you are not only investing in quality but also contributing to sustainable practices within your industry.

6. Customizable Sizes: Available in a variety of widths and lengths to suit your specific project requirements, our Matte Finish Polypropylene Film can be tailored to fit any application seamlessly.

7. User-Friendly Handling: The lightweight nature of this film makes it easy to handle during production processes while maintaining its structural integrity throughout its lifecycle.

Conclusion:

As an established exporter in the industry, we offer competitive bulk prices for our Matte Finish Polypropylene Film, making it an economical choice for businesses looking to bulk buy. Our wholesale options are designed to cater to both small enterprises and large corporations, allowing you to procure the necessary quantities without compromising on quality.

We understand that many businesses require tailored solutions; therefore, we also provide OEM services to meet specific requirements. Whether you need custom sizes or unique specifications, our team is dedicated to working closely with you to deliver a product that aligns perfectly with your needs.

In summary, our Matte Finish Polypropylene Film stands out as a reliable choice for businesses seeking high-quality materials at competitive prices. With our extensive experience as a producer in the industry, we are committed to providing exceptional service and support throughout your purchasing journey. Choose us as your trusted partner for all your polypropylene film needs—where quality meets affordability in every roll.