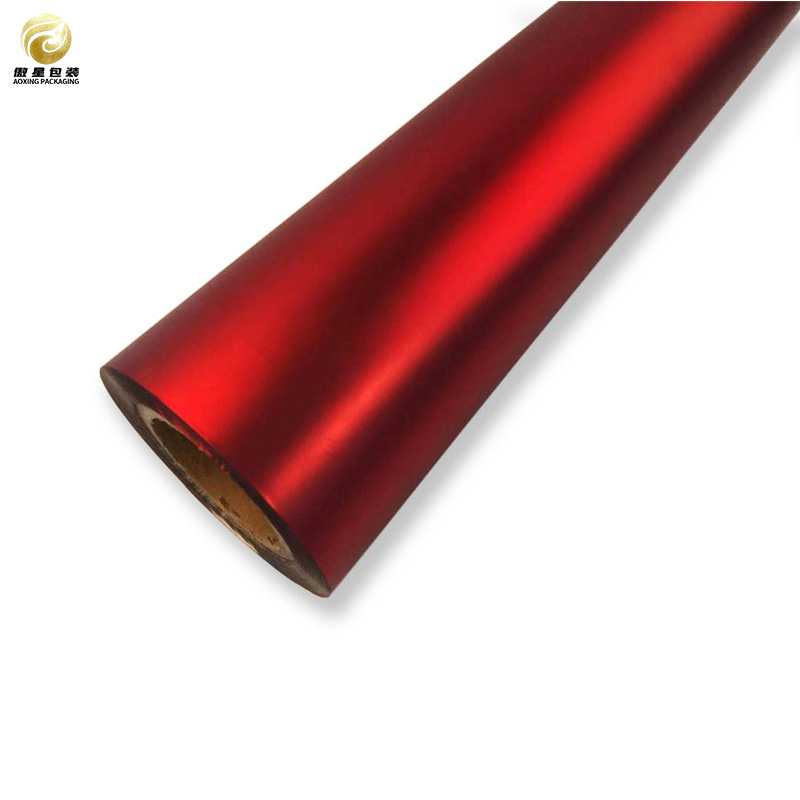

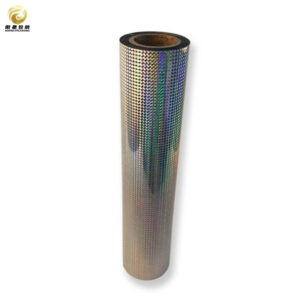

Non-Glossy Polypropylene Film

| Product | Matte OPP Film |

| Material | OPP + color+ aluminum layer / OPP + aluminum + color layer |

| Thickness | 15um;18um |

| Color Option | Red,Blue,Purple,Green,Gold,Yellow,Rose,Rainbow,etc. |

| Width & Length | Width:500~1800mm Length:Customized |

Detailed Descriptions

Product Description: Non-Glossy Polypropylene Film

Introducing our premium Non-Glossy Polypropylene Film, a versatile and high-performance material designed to meet the diverse needs of various industries. Engineered for durability and functionality, this film is an ideal choice for applications requiring a non-reflective surface without compromising on quality or clarity.

Key Features:

1. Superior Clarity and Printability: Our Non-Glossy Polypropylene Film offers excellent optical clarity, making it suitable for high-quality printing applications. The non-reflective surface enhances visibility and readability, ensuring that your graphics and text stand out without glare.

2. Durable and Resilient: Crafted from high-grade polypropylene, this film exhibits exceptional strength and resistance to tearing, puncturing, and moisture. Its robust nature makes it ideal for both indoor and outdoor applications, ensuring longevity even in challenging environments.

3. Eco-Friendly Composition: Committed to sustainability, our Non-Glossy Polypropylene Film is produced from recyclable materials. This environmentally friendly option allows businesses to reduce their carbon footprint while still achieving outstanding performance.

4. Versatile Applications: This film is perfect for a wide range of uses, including packaging, labeling, signage, and promotional materials. Its non-glossy finish makes it particularly suitable for applications where glare reduction is essential, such as in retail displays or educational materials.

5. Easy Handling and Processing: Designed for convenience, our Non-Glossy Polypropylene Film can be easily cut, folded, or laminated without compromising its integrity. It is compatible with various printing methods including flexography, digital printing, and offset printing, making it a flexible choice for manufacturers and designers alike.

6. Temperature Resistance: This film maintains its performance across a wide temperature range, ensuring that it remains stable in both hot and cold conditions. This feature makes it an excellent choice for products that may be exposed to varying environmental factors.

7. Customizable Options: We understand that every project has unique requirements. Our Non-Glossy Polypropylene Film is available in various thicknesses and widths to accommodate specific needs. Custom printing options are also available to help you achieve the perfect look for your brand.

As a reputable manufacturer, we understand the importance of providing products that not only perform well but also offer cost-effective options for bulk purchases. Our Non-Glossy Polypropylene Film is available for bulk buy at competitive wholesale prices, allowing businesses to optimize their procurement processes while maintaining quality. Whether you are looking to stock your inventory or fulfill large orders, our bulk pricing structure is designed to accommodate your needs.

We are also a trusted exporter, delivering our Non-Glossy Polypropylene Film to clients around the globe. Our extensive experience in international trade ensures that your orders are handled with care and efficiency, allowing you to focus on your core business operations. Additionally, we offer OEM services tailored to your specific requirements, enabling you to customize the film according to your branding and application needs.

Choosing our Non-Glossy Polypropylene Film means partnering with a reliable supplier that values quality and customer satisfaction. With our commitment to providing exceptional products at bulk prices, you can trust us as your go-to source for all your polypropylene film needs. Experience the difference that comes from working with a dedicated manufacturer who understands the intricacies of the market and is ready to support your business growth.

For inquiries about bulk buy options or to discuss wholesale pricing, please contact us today. Let us help you elevate your packaging solutions with our superior Non-Glossy Polypropylene Film.