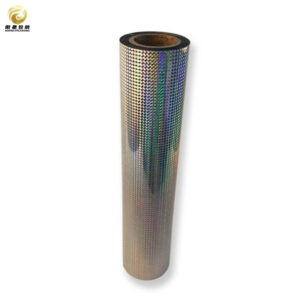

Transparent OPP Sheet

| Product | Transparent OPP Film |

| Material | OPP+ color+ aluminum layer / OPP + aluminum + color layer |

| Thickness | 15um; 18um |

| Color Option | Red,Blue,Purple,Green,Gold,Yellow,Rose,Rainbow,etc. |

| Width & Length | Width:500~1800mm Length:Customized |

Detailed Descriptions

Product Description: Transparent OPP Sheet

Elevate your packaging solutions with our premium Transparent OPP (Oriented Polypropylene) Sheet, meticulously designed to meet the diverse needs of various industries. This high-quality, transparent film is engineered for durability and clarity, making it an ideal choice for businesses seeking both functionality and aesthetic appeal in their packaging materials.

Key Features:

1. Exceptional Clarity: Our Transparent OPP Sheet boasts superior optical clarity, allowing for maximum visibility of the packaged products. This feature enhances product presentation, making it perfect for retail displays, gift wrapping, and promotional packaging.

2. Durability and Strength: Crafted from high-grade polypropylene, this sheet exhibits remarkable tensile strength and resistance to tearing. Its robust nature ensures that your products are well-protected during storage and transportation, reducing the risk of damage.

3. Versatile Applications: The Transparent OPP Sheet is suitable for a wide range of applications, including food packaging, stationery products, crafts, and more. Its versatility makes it an essential material for manufacturers, retailers, and crafters alike.

4. Eco-Friendly Option: As a recyclable material, our OPP sheets contribute to sustainable practices in packaging. By choosing our Transparent OPP Sheet, you are not only ensuring quality but also supporting environmentally responsible initiatives.

5. Easy to Work With: The lightweight nature of the sheet allows for easy handling and processing. It can be easily cut, folded, or sealed using standard packaging equipment or manual methods, making it a convenient choice for any production line.

6. Moisture Resistance: The inherent moisture barrier properties of OPP sheets help protect contents from humidity and moisture damage. This feature is particularly beneficial for food items and other sensitive products that require a dry environment.

7. Customizable Options: We understand that every business has unique requirements. Our Transparent OPP Sheets are available in various thicknesses and sizes to cater to your specific needs. Custom printing options are also available to enhance branding efforts.

Applications:

– Retail Packaging: Ideal for showcasing products while providing protection. – Food Packaging: Perfect for wrapping snacks, baked goods, and other consumables. – Craft Projects: A favorite among crafters for scrapbooking and DIY projects. – Stationery Products: Excellent for wrapping notebooks, cards, and other stationery items.

Conclusion:

As a reputable exporter, we understand the importance of reliability and efficiency in the supply chain. We offer competitive bulk prices for businesses looking to bulk buy our Transparent OPP Sheets. Whether you are a small business or a large corporation, our wholesale options cater to all scales of operation. By choosing us as your trusted partner, you can benefit from our extensive experience as an OEM (Original Equipment Manufacturer), allowing for customized solutions tailored specifically to your requirements.

Our factory is equipped with advanced machinery that enables us to produce high volumes of Transparent OPP Sheets without compromising on quality. This capability positions us as a preferred producer in the market, ensuring that you receive consistent products that align with your brand’s standards.

In summary, if you are seeking a reliable manufacturer and supplier of Transparent OPP Sheets in China, look no further. Our commitment to excellence, combined with our competitive pricing and dedication to customer satisfaction, makes us the ideal choice for your packaging needs. Contact us today to explore how we can support your business with our exceptional products and services.