What Are Metalized Polyester Films and What Are Their Unique Properties?

Metalized polyester films are special materials made by coating a thin layer of metal onto a polyester base film. The polyester, often polyethylene terephthalate (PET), acts as a strong, flexible support, while the metal layer gives the film unique properties like reflectivity and barrier protection. This combination creates a versatile film used in many industries.

Definition and Basic Composition

At its core, a metalized polyester film consists of a polyester substrate covered with a very thin metal layer. This metal layer is usually just a few nanometers thick but transforms the film’s behavior and appearance. The polyester base provides toughness, clarity, and flexibility, while the metal adds gloss, reflectivity, and acts as a barrier against gases and moisture.

Metals Commonly Used in Metalized Polyester Films

Several metals can be applied to polyester films, each offering different features:

- Aluminum (Al): The most common, it provides excellent moisture, oxygen, and light barriers along with high reflectivity.

- Tin (Sn): Adds corrosion resistance and is sometimes applied for specific packaging needs.

- Chromium (Cr): Offers enhanced durability and corrosion protection.

- Copper (Cu): Used mainly for thermal and electrical conductivity; also valued for its rich color.

- Silver (Ag): Highly reflective and conductive, ideal for electronics and solar applications.

- Zinc (Zn): Notable for its antimicrobial properties, used in hygiene-sensitive packaging and agriculture.

Each metal layer influences film properties, such as reflectivity, conductivity, and barrier effectiveness.

How Is Metal Applied to Polyester Films?

The metal layer is typically applied through a process called vacuum metallization. In this method, metal is vaporized in a vacuum chamber and then condenses onto the cold polyester film surface, forming a uniform, thin coating.

Another technique is sputtering, where ions bombard a metal target, releasing metal atoms that settle on the film. Both methods achieve strong adhesion and uniform coverage without compromising film flexibility.

Key Physical Properties of Metalized Polyester Films

Metalized polyester films stand out because of these main physical traits:

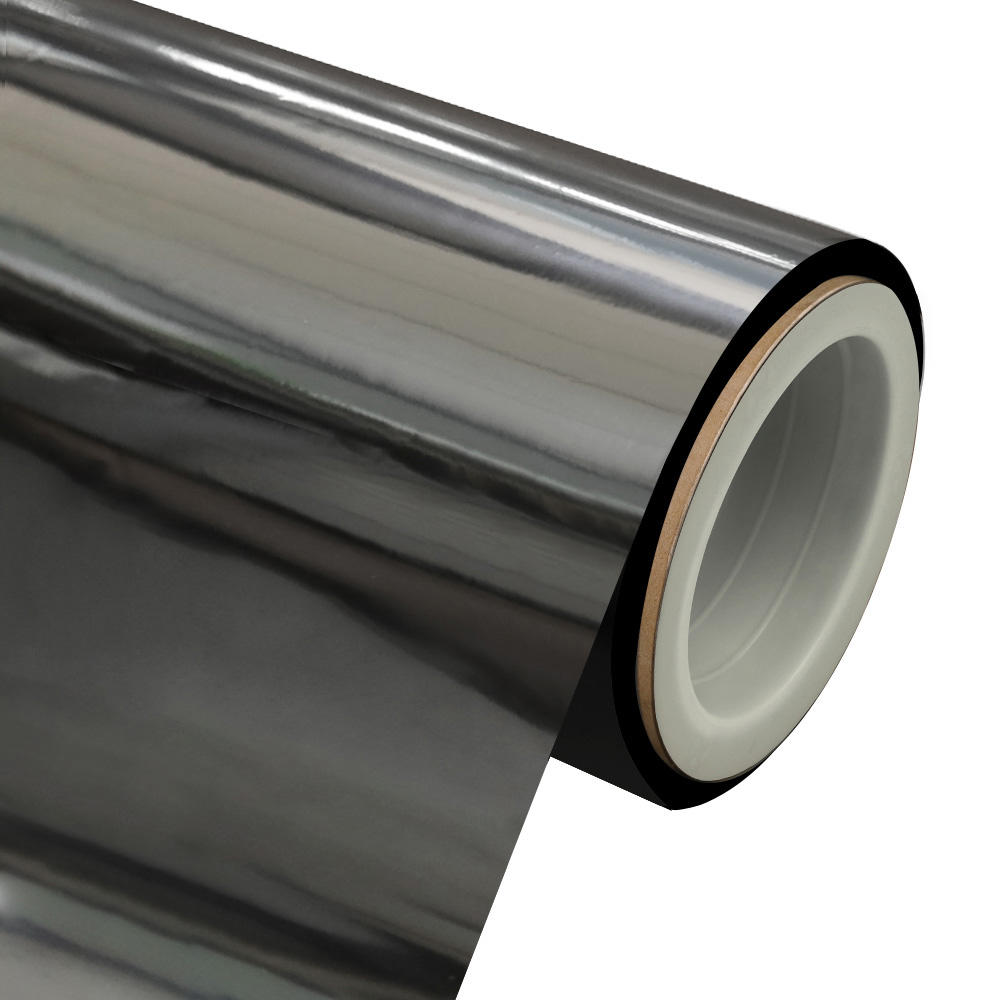

- High Reflectivity: Aluminum coating can reflect up to 90% of light, making these films shiny and eye-catching.

- Glossiness: The smooth metal layer gives the film a glossy finish used in packaging and decorative applications.

- Dimensional Stability: Polyester films resist stretching or shrinking, even when metalized. This stability helps keep printed images sharp.

- Thermal Stability: These films can tolerate temperatures often between -70°C and 150°C without losing shape or properties.

- Flexibility: Unlike metal foils, metalized polyester films stay flexible and resist cracking when bent or folded.

These physical properties make metalized polyester films suitable for demanding uses where light reflection, heat resistance, and handling performance are critical.

Chemical Properties and Barrier Characteristics

The metal layer also acts as a strong barrier to harmful substances:

- Moisture Resistance: Metal layers reduce water vapor permeation by up to 100 times compared to plain polyester. This keeps products dry longer.

- Oxygen Barrier: Oxygen penetration decreases dramatically, slowing oxidation reactions that spoil food or degrade chemicals.

- UV Light Blocking: Metalized films reduce UV transmittance, protecting sensitive products from harmful radiation.

- Odor Barrier: They prevent exchange of odors, which preserves flavors and aromas in packaged goods.

This combination of chemical resistance and barrier protection extends product shelf life and ensures safety.

Effects of Texturing and Surface Coatings

Adding silica particles or other textures on the film surface creates a controlled roughness. This texturing changes properties:

- Light Scattering: Textured surfaces spread light, reducing glare but increasing diffusivity.

- Surface Grip: Rougher surface improves print adhesion and handling.

- Reflectivity: While slightly lowering reflectance, it enhances visual effects like sparkle.

These coatings are used to customize film features for specific packaging or display needs.

Comparison to Plain Polyester Films and Aluminum Foil

| Property | Plain Polyester Film | Metalized Polyester Film | Aluminum Foil |

|---|---|---|---|

| Reflectivity | Low | Very High | Very High |

| Flexibility | High | High (slightly stiffer) | Low (cracks when bent) |

| Barrier to Moisture | Moderate | Excellent | Excellent |

| Barrier to Oxygen | Moderate | Excellent | Excellent |

| Tear Resistance | Good | Better due to metal layer | Poor to moderate |

| Weight | Light | Light | Heavy |

| Durability | Moderate | High | Moderate |

| Corrosion Resistance | Not applicable | Excellent | Poor (oxidizes easily) |

Metalized polyester films blend the best of both worlds: the lightweight and flexible nature of polymers, and the barrier and reflective properties of metals.

What Makes Metalized Polyester Films Durable and Abrasion/Corrosion-Resistant?

The durability of metalized polyester films comes from the strong adhesion of the metal layer to the polyester base and the intrinsic properties of both materials. Proper vacuum metallization creates a uniform coating that sticks well, preventing peeling and cracking.

These films resist abrasion better than uncoated films because the metal layer forms a protective shell. They also resist corrosion since metals like aluminum naturally form oxide layers that prevent further degradation.

Unlike aluminum foils, metalized films don’t wrinkle easily, making them excellent for packaging and industrial use.

Exploring the unique properties of metalized polyester films highlights their role as a vital material. The combination of metal and polyester film delivers benefits ranging from high reflectivity to robust barrier protection and exceptional durability. These features make metalized polyester films the top choice for packaging, electronics, insulation, and decorative uses.

How Are Metalized Polyester Films Manufactured and What Are Their Technical Advantages?

Metalized polyester films are created by coating a thin layer of metal onto a polyester base. This process affects the film’s thickness, strength, barrier properties, and overall quality. Let me walk you through the manufacturing methods and why these films shine technically.

Metalizing Process: Vacuum Metallization, Sputtering, and Coating Methods

The most common way to make metalized polyester films is vacuum metallization. Here’s how it works:

- Vacuum Metallization: The polyester film passes through a vacuum chamber. Inside, aluminum (or sometimes chromium, tin, copper, or silver) is heated until it vaporizes. This vapor settles on the polyester film, forming a thin, even metal layer.

- Sputtering: In this method, metal atoms are knocked from a solid metal target by high-energy ions and then deposited onto the polyester film. This allows for very precise control over the metal layer thickness.

- Coating Methods: Sometimes, metal powders are mixed with binders and applied as a liquid coating. Once dried, this introduces special textures or effects.

Each method controls the metal layer differently, affecting reflectivity, thickness, and adhesion. Vacuum metallization is favored for producing smooth, continuous metal layers that cling well to the polyester film.

Impact of Manufacturing on Thickness, Uniformity, and Adhesion

The process must balance these factors carefully:

| Factor | Description | Importance |

|---|---|---|

| Thickness | Usually between 20 to 100 nanometers | Controls reflectivity and barrier strength |

| Uniformity | Even distribution prevents weak spots and defects | Ensures consistent optical and barrier properties |

| Adhesion | Strong bonding between metal and polyester | Prevents peeling during handling or use |

Proper substrate cleaning, vacuum quality, and metal vapor control ensure uniform metal coverage with strong adhesion.

Mechanical Properties Gained Through Metalizing

Adding metal enhances the base polyester film mechanically. Here are key improvements:

- Tensile Strength: Metal layers reinforce the structure, making the film less likely to stretch or break.

- Tear Resistance: The metal coating prevents easy tearing and pinholing.

- Flexibility: Despite extra metal, these films bend and fold easily without cracking.

- Dimensional Stability: Metalized films resist shrinking or swelling under heat and moisture changes better than plain films.

Compared to uncoated polyester, metalized films are tougher and last longer in demanding conditions.

Gas Barrier Quality: Keeping Oxygen and Moisture Out

One standout benefit is how metalized polyester blocks gases:

- The thin metal layer acts as a barrier to water vapor and oxygen.

- Gas permeability drops by up to 100 times, compared to conventional polymer films.

- This quality helps extend shelf life in food packaging by keeping moisture and air out.

Compared to aluminum foil, metalized films are lighter and more flexible but still provide superior protection relative to most plastics.

Microwave Compatibility and Thermal Insulation

Metalized polyester plays important roles in heating and insulation:

- Microwave Use: The metal layer is thin enough to allow microwaving certain packaged foods safely, as it reflects microwaves differently than thicker metal foils.

- Thermal Insulation: High reflectivity bounces heat, lowering heat transfer through walls or packaging. Applications include thermal blankets, automotive insulation, and reflective barriers.

This combination of microwave friendliness and heat reflection extends the film’s applications beyond packaging.

Peelable vs. Non-Peelable Metalized Polyester Films

Not all metalized films perform the same. There are two main types for packaging:

- Peelable Films: The metal coating can separate easily from the substrate or backing layers. Useful in resealable lids or tamper-evident packaging.

- Non-Peelable Films: The metal bonds tightly for durability and protection; used in products needing long shelf life and mechanical strength.

Choosing between peelable and non-peelable depends on the product type, user convenience, and packaging machinery compatibility.

Printability, Machinability, and Packaging Equipment Compatibility

Metalized polyester films score high for print and production processes:

- They accept various inks (UV, solvent-based, water-based) well due to smooth metal surfaces.

- Their stiffness and toughness support high-speed rolling and cutting machines with little jamming.

- Metalized films are compatible with many packaging machines such as HFFS (Horizontal Form Fill Seal) and VFFS (Vertical Form Fill Seal) that produce bags and pouches.

This smooth integration reduces production downtime and enhances package appeal.

Corrosion Resistance and Freshness Maintenance

Metal layers protect packaged goods by:

- Resisting Corrosion: Aluminum and chromium coatings prevent oxidation and moisture infiltration.

- Preserving Freshness: Their excellent oxygen and moisture barriers prevent spoilage for food, pharmaceuticals, and chemicals.

Moreover, metalized films maintain the product’s aroma and flavor by blocking external odors. This feature is critical for spices, coffee, and powdered nutrition products.

Key Technical Benefits at a Glance

| Technical Advantage | Effect on Film Performance | Application Examples |

|---|---|---|

| Excellent Reflectivity | Enhances visibility and aesthetics | Automotive trims, advertising displays |

| Strong Barrier Properties | Extends product shelf life | Food, pharmaceuticals packaging |

| Mechanical Strength | Resists tearing and puncture | Snacks packaging, labels |

| Thermal Stability and Insulation | Reflects heat for energy efficiency | Thermal blankets, insulation in vehicles |

| Microwave Compatibility | Enables microwave-safe packaging | Ready meals packaging |

| Corrosion Resistance | Protects against oxidation and moisture damage | Electronics insulation, foil replacement |

| Print and Machine Compatibility | Supports high-quality printing and fast packaging | Beverage labels, flexible pouches |

Each feature results from precise metalized polyester films manufacturing controls, which maximize performance while keeping the film lightweight and flexible.

Exploring the unique properties of metalized polyester films reveals how their manufacturing shapes outstanding technical benefits. From barrier strength to mechanical toughness and thermal functions, each step in metalized PET film production crafts a versatile film that meets diverse industrial needs.

What Are the Common Applications and Market Trends of Metalized Polyester Films?

Metalized polyester films are versatile materials used widely across many industries. Their unique qualities—like high reflectivity, strong barrier protection, and durability—make them highly valued in food packaging, electronics, thermal insulation, automotive, and graphic design. Let me take you through these industries and how these films impact product performance and market trends.

Industries Using Metalized Polyester Films

Food packaging is a major user of metalized polyester films. The films act as an excellent barrier to moisture, oxygen, and light. This barrier can reduce gas permeation by up to 100 times compared to regular plastic films. This keeps food fresh and safe for longer. You'll find them in packaging for products like cocoa powder, powdered nutrition drinks, spices, and oatmeal. The films also preserve the scent, flavor, and aroma of products without adding heavy metals.

In pharmaceutical packaging, metalized films protect medicines from moisture and oxygen degradation. They maintain product stability and safety by blocking UV light and contaminants.

The electronics industry uses metalized polyester films for electromagnetic interference (EMI) shielding to prevent signal noise in devices. These films also serve in flexible printed circuits and antistatic packaging to protect sensitive components during storage and transport.

For thermal insulation, metalized films reflect radiant heat, helping with energy efficiency. They are found in foam boards, bubble wraps, and flexible blankets used in buildings, vehicles, and aerospace. Their low thermal conductivity improves insulation, reduces energy costs, and enhances user comfort.

The automotive sector employs metalized polyester in decorative trims and interiors, owing to their high reflectivity, durability, and resistance to abrasion and corrosion.

Lastly, in graphics and consumer products, metalized films enhance aesthetics. They are widely used in decorative laminates, labels, signage, and advertising displays. Their glossy metallic finish creates standout packaging and branding elements.

How Metalized Films Enhance Shelf Life and Safety

Metalized polyester films improve shelf life through their superior barrier protection. By minimizing oxygen and moisture penetration, these films slow down oxidation, moisture damage, and microbial growth. The result is an extended shelf life for perishable goods.

In pharmaceuticals, the films maintain drug potency by shielding products from light-induced degradation. Metalized films' resistance to aroma loss also protects flavors and freshness.

They come in peelable and non-peelable formats for lids and pouches, allowing ease of use without compromising the barrier.

Roles in Electronics

The metal layer in these films provides important electrical conductivity and shielding properties. EMI shielding prevents interference between multiple electronic components. This is crucial in devices like smartphones and computers.

Flexible circuits embedded in metalized films enable compact designs and reliable connections in wearable technology and flexible displays.

Antistatic packaging made from metalized polyester prevents static charge build-up, reducing the risk of electrostatic discharge that could damage electronic parts.

Thermal Insulation Benefits

Metalized polyester films play a vital role in insulating buildings, vehicles, and aerospace crafts by reflecting infrared radiation. This reduces heat loss in winter and heat gain in summer.

Thermal insulation products containing these films, such as reflective bubble wraps, have become popular for enhancing energy efficiency, reducing HVAC costs, and improving user comfort.

Their low weight and flexibility make them ideal for aerospace applications where reducing mass is critical.

Decorative and Branding Uses

Besides technical advantages, these films provide a high-gloss metallic finish that improves product look and feel. They are often used in:

- Decorative laminates in interiors and automotive trims

- Labels and wrap-around labels with high optical density and universal printability

- Signage and point-of-sale materials to catch consumer attention

The films support various printing techniques, including flexography, UV, and offset printing, enhancing branding opportunities.

Environmental Considerations

Although metalized polyester films feature a metal layer, their recycling can be challenging. Separating the thin aluminum or other metals from the polyester substrate requires specialized technologies.

However, compared to conventional aluminum foils, metalized polyester films offer sustainability advantages. They are lighter, require less metal, reduce shipping weight, and save energy in transportation.

Emerging innovations include bio-degradable metallized films and multi-layer laminates that maintain barrier properties but improve recyclability or compostability.

With evolving recycling infrastructure, more metalized films can enter the recycled materials stream, reducing landfill waste.

Emerging Market Trends

The market for metalized polyester films is growing fast. In India, for instance, the industry is expected to grow at a compound annual growth rate (CAGR) of around 26.7% over the next five years. This surge reflects:

- Rising demand for safe and sustainable food packaging

- Consumer preference for fresh, longer-lasting products

- Growth in electronics and automotive sectors

- Innovations in end-use applications and materials technology

There is a strong trend toward specialty films with improved barrier properties or ecological benefits. For example, films with oxo-biodegradable layers or bright white backings for enhanced printability are gaining traction.

Selection Criteria for Metalized Polyester Films

Choosing the right metalized polyester film depends on the product and packaging needs:

| Criteria | Considerations |

|---|---|

| Product sensitivity | Protection needed from light, oxygen, moisture, or odor |

| Barrier level required | How much moisture or oxygen ingress is acceptable |

| Packaging equipment compatibility | Film thickness and machinability for HFFS, VFFS, or reel-fed |

| Shelf life extension goal | Duration for maintaining freshness or drug potency |

| Aesthetic needs | Gloss finish, color options, print quality |

| Environmental impact | Whether recycled or bio-degradable options are preferred |

| Peelability | Need for resealable or easy-open packaging |

| Industry | Primary Application | Key Benefits |

|---|---|---|

| Food Packaging | Barrier films for snacks, powders, spices | Extended shelf life, odor and moisture control |

| Pharmaceuticals | Protective blister and pouch packaging | UV blocking, oxygen barrier |

| Electronics | EMI shielding, flexible circuits, antistatic packaging | Signal integrity, component protection |

| Thermal Insulation | Reflective blankets, foam board coverings | Heat reflection, energy savings |

| Automotive | Decorative trims, interior laminates | Abrasion resistance, aesthetic appeal |

| Graphics & Branding | Labels, signage, decorative laminates | High gloss, printability |

This comprehensive look at metalized polyester films applications reveals their vast importance across industries. They extend shelf life, improve safety, contribute to energy savings, and enhance aesthetics. Ongoing innovations and market trends indicate continued growth and new uses for these versatile films.

FAQs about Explore the unique properties of metalized polyester films

What are metalized polyester films and what are their unique properties?

Metalized polyester films are made by coating a thin metal layer onto a polyester base film, combining polyester’s flexibility with metal’s reflectivity and barrier protection. This results in films that are highly reflective, glossy, flexible, dimensionally and thermally stable, and provide excellent moisture, oxygen, UV, and odor barriers.

How is metal applied to polyester films during manufacturing?

Metal is typically applied to polyester films by vacuum metallization, where metal vapor condenses on the film surface, or by sputtering, which uses ion bombardment to deposit metal atoms uniformly. These processes ensure strong adhesion, consistent coating thickness, and maintain the film’s flexibility.

What technical advantages do metalized polyester films have?

Metalized polyester films show enhanced tensile strength, tear resistance, dimensional and thermal stability, and gas barrier properties that reduce oxygen and moisture permeability by up to 100 times. They also support microwave compatibility, high reflectivity, corrosion resistance, and compatibility with printing and packaging equipment.

In which industries and applications are metalized polyester films commonly used?

Metalized polyester films are widely used in food and pharmaceutical packaging for shelf life extension, electronics for EMI shielding and antistatic protection, thermal insulation in buildings and vehicles, automotive decorative trims, and graphics for glossy, eye-catching finishes.

How do metalized polyester films enhance product shelf life and

Metalized polyester films combine metal layers with strong polyester for unique benefits. They offer high reflectivity, durability, and excellent moisture barriers. The metalizing process shapes their thickness and adhesion, improving strength and flexibility. These films protect food, electronics, and more, extending shelf life and boosting performance. Market demand grows with new trends and sustainability efforts. Understanding their properties and uses helps you choose the right film for your needs. Metalized polyester films stand out as reliable, versatile materials in many industries.