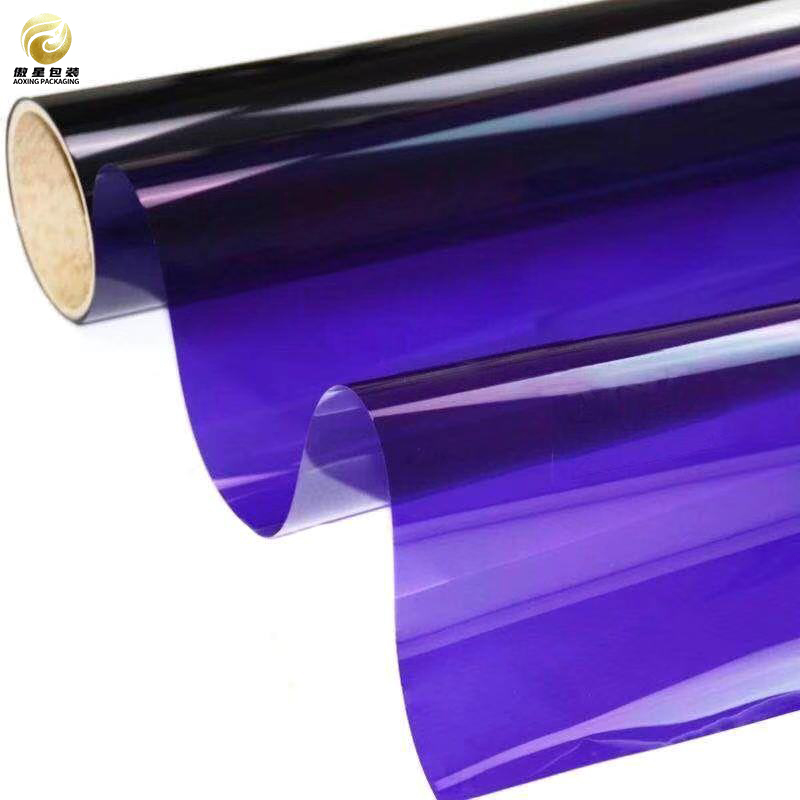

Clear Plastic OPP Film

| Product | Transparent OPP Film |

| Material | OPP+ color+ aluminum layer / OPP + aluminum + color layer |

| Thickness | 15um; 18um |

| Color Option | Red,Blue,Purple,Green,Gold,Yellow,Rose,Rainbow,etc. |

| Width & Length | Width:500~1800mm Length:Customized |

Detailed Descriptions

Product Description: Clear Plastic OPP Film

Introducing our premium Clear Plastic OPP (Oriented Polypropylene) Film, a versatile and high-performance packaging solution designed to meet the diverse needs of various industries. Engineered with precision and manufactured to the highest standards, this film is ideal for applications ranging from food packaging to retail displays, ensuring that your products are not only protected but also presented in an appealing manner.

Key Features:

1. Exceptional Clarity and Transparency: Our Clear OPP Film boasts outstanding optical clarity, allowing for maximum visibility of packaged products. This feature enhances product presentation, making it an excellent choice for retail packaging where visual appeal is paramount.

2. Durability and Strength: Constructed from high-quality polypropylene, this film exhibits remarkable tensile strength and resistance to tearing. Its robust nature ensures that it can withstand the rigors of handling and transportation, providing reliable protection for your products.

3. Moisture and Grease Resistance: The inherent properties of OPP Film make it resistant to moisture and grease, safeguarding your products from environmental factors that could compromise quality. This feature is particularly beneficial for food packaging applications, where freshness is critical.

4. Eco-Friendly Option: Our Clear Plastic OPP Film is a recyclable material, aligning with sustainable practices and reducing environmental impact. By choosing this film, you contribute to a greener future while maintaining high-quality packaging standards.

5. Versatile Applications: This film is suitable for a wide range of applications including food packaging (snack foods, confectionery, bakery items), retail packaging (gift wrapping, product displays), and industrial uses (protective covers). Its adaptability makes it an essential component in any packaging strategy.

6. Easy to Print On: The surface of our Clear OPP Film is designed for optimal printability, allowing for vibrant graphics and branding elements to be applied effortlessly. This feature enhances marketing efforts by enabling businesses to create eye-catching designs that resonate with consumers.

7. Customizable Options: We understand that every business has unique requirements. Therefore, we offer customizable sizes and thicknesses to cater to specific needs. Whether you require small rolls for intricate designs or larger formats for bulk packaging, we have the solution for you.

8. User-Friendly Handling: Our Clear Plastic OPP Film is lightweight yet easy to handle during application processes such as sealing or wrapping. Its flexibility allows for seamless integration into existing production lines without compromising efficiency.

IAs a reputable exporter with years of experience in the market, we understand the importance of reliability and consistency in supply. Our factory is equipped to handle both small and large orders, making it easy for you to bulk buy according to your specific requirements. We offer competitive bulk prices that cater to businesses seeking wholesale options without compromising on quality.

In addition to our standard offerings, we also provide OEM services tailored to your unique specifications. Whether you need custom sizes or specific features, our dedicated team is here to assist you in creating the perfect solution for your packaging needs.

Partner with us today as your trusted producer of Clear Plastic OPP Film. With our commitment to excellence and customer satisfaction, you can rest assured that you are receiving top-notch products at unbeatable prices. Contact us now to learn more about our offerings and how we can support your business with reliable packaging solutions.