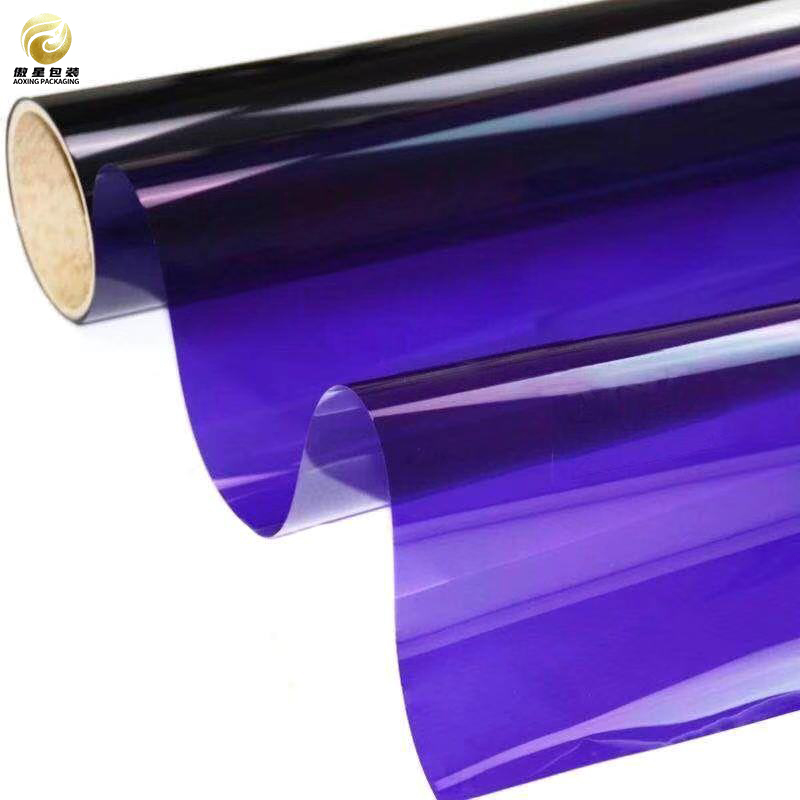

Película PET de superficie brillante

| Producto | Película PET de alto brillo |

| Material | PET + color+ capa de aluminio / PET + aluminio + capa de color |

| Espesor | 12~188um |

| Opción de color | Rojo, azul, púrpura, verde, oro, amarillo, rosa, arco iris, etc. |

| Anchura y longitud | Anchura:500~1800mm Longitud:Personalizada |

Descripciones detalladas

Product Description: Glossy Surface PET Film

Introducing our premium Glossy Surface PET Film, a versatile and high-performance material designed to meet the diverse needs of various industries. Engineered from top-quality polyethylene terephthalate (PET), this film combines exceptional clarity with a sleek, glossy finish, making it an ideal choice for applications that demand both aesthetic appeal and durability.

Key Features:

1. Superior Clarity and Gloss Finish: Our Glossy Surface PET Film boasts an outstanding optical clarity that enhances the visual impact of printed graphics and images. The glossy finish not only elevates the overall appearance but also provides a vibrant backdrop that makes colors pop, ensuring your designs stand out.

2. Exceptional Durability: This film is engineered to withstand the rigors of everyday use. Its robust structure offers excellent resistance to tearing, puncturing, and abrasion, making it suitable for both indoor and outdoor applications. The inherent properties of PET also provide resistance to moisture and chemicals, ensuring longevity in various environments.

3. Versatile Applications: The versatility of our Glossy Surface PET Film makes it suitable for a wide range of applications, including packaging, labels, signage, and promotional materials. Whether you are creating eye-catching product packaging or durable labels that need to withstand handling, this film delivers reliable performance across all uses.

4. Easy to Print On: Designed for compatibility with various printing technologies, including digital printing, flexography, and screen printing, our PET film allows for seamless integration into your production processes. Its smooth surface ensures excellent ink adhesion and vibrant color reproduction, enabling you to achieve stunning results with every print run.

5. Eco-Friendly Option: As part of our commitment to sustainability, our Glossy Surface PET Film is recyclable and produced in compliance with environmental regulations. By choosing this product, you are not only investing in quality but also contributing to a greener future.

6. Customizable Sizes and Thicknesses: We understand that every project has unique requirements. That’s why we offer our Glossy Surface PET Film in a variety of sizes and thicknesses to accommodate your specific needs. Whether you require large rolls for industrial applications or smaller sheets for craft projects, we have the right solution for you.

Conclusion:

Our Glossy Surface PET Film is ideal for packaging, labeling, and graphic applications, offering superior clarity and a sleek finish that enhances visual appeal. This film is engineered to provide excellent durability, resistance to moisture, and UV protection, making it suitable for both indoor and outdoor use. Whether you are looking for a reliable solution for your packaging needs or seeking materials for promotional displays, our PET film stands out as an optimal choice.

As an experienced exporter in the industry, we understand the importance of competitive pricing. We offer bulk buy options that allow businesses to benefit from wholesale rates without compromising on quality. Our bulk price structure is designed to accommodate various order sizes, ensuring that you receive the best value for your investment.

We also specialize in OEM services, allowing you to customize the Glossy Surface PET Film according to your specific requirements. Our dedicated team works closely with clients to ensure that every aspect of the product meets their expectations, from thickness and size to packaging options.

In summary, our Glossy Surface PET Film is not only a product of superior quality but also a testament to our dedication as a leading producer in the market. Partner with us today for all your film needs and experience the reliability of a manufacturer that prioritizes excellence in every roll. Contact us now to discuss your requirements or place an order at competitive bulk prices!