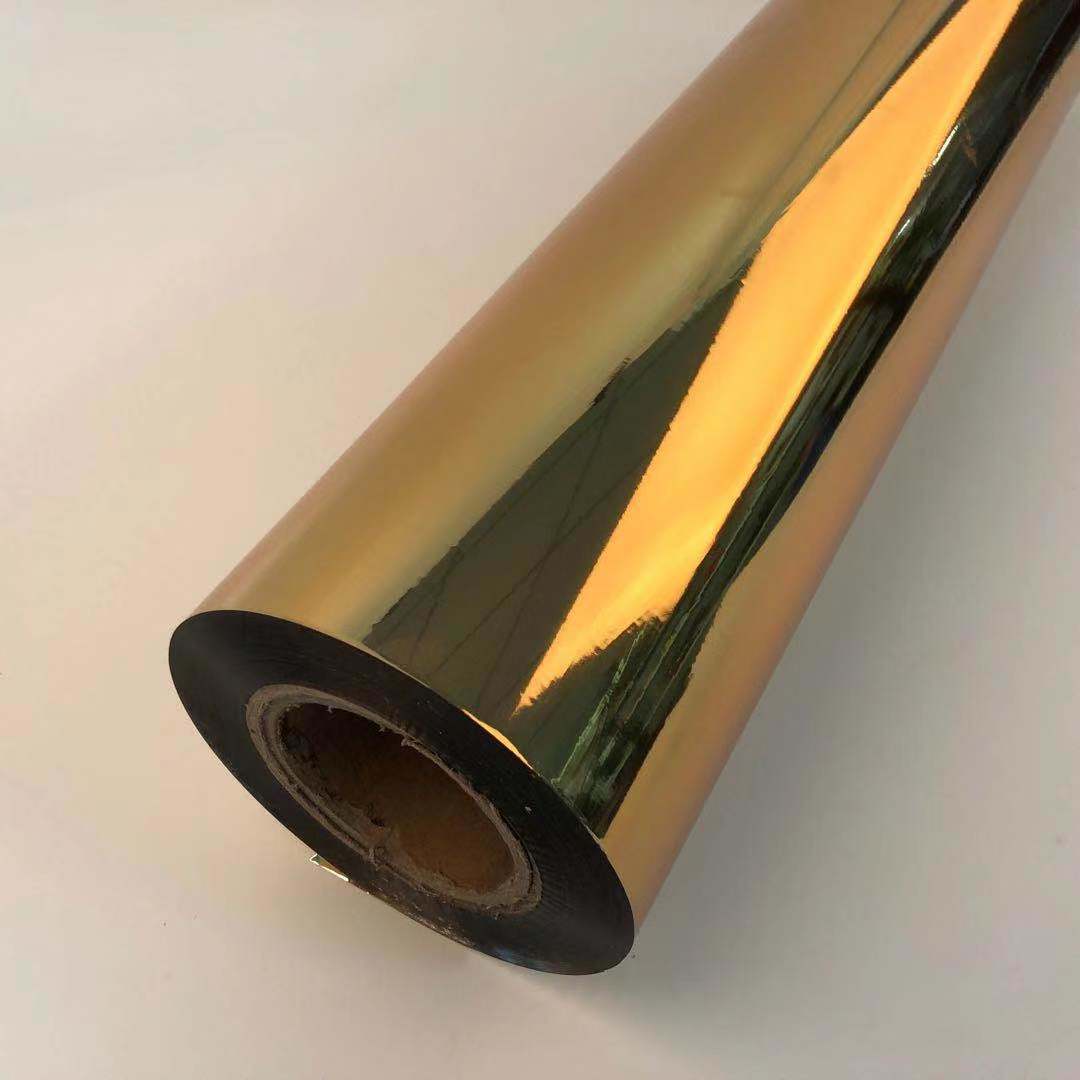

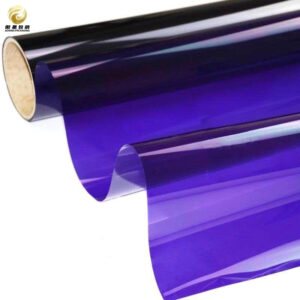

Película de OPP recubierta de aluminio

| Producto | Película OPP metalizada |

| Material | OPP + color+ capa de aluminio / OPP + aluminio + capa de color |

| Espesor | 15um;18um |

| Opción de color | Rojo, azul, púrpura, verde, oro, amarillo, rosa, arco iris, etc. |

| Anchura y longitud | Anchura:500~1800mm Longitud:Personalizada |

Descripciones detalladas

Product Description: Aluminum Coated OPP Film

Introducing our premium Aluminum Coated OPP Film, a cutting-edge packaging solution designed to meet the diverse needs of modern industries. This high-performance film combines the durability of oriented polypropylene (OPP) with a sophisticated aluminum coating, resulting in a product that excels in both functionality and aesthetics.

Key Features:

1. Superior Barrier Properties: The aluminum coating provides exceptional barrier protection against moisture, oxygen, and light, ensuring that your products remain fresh and uncontaminated. This makes our Aluminum Coated OPP Film an ideal choice for packaging food items, pharmaceuticals, and other sensitive materials.

2. Enhanced Aesthetic Appeal: The reflective surface of the aluminum coating not only enhances the visual appeal of your packaging but also adds a layer of sophistication. This feature is particularly beneficial for brands looking to elevate their product presentation and attract consumer attention on retail shelves.

3. Versatile Applications: Our Aluminum Coated OPP Film is suitable for a wide range of applications, including flexible packaging, lamination, labels, and more. Its versatility makes it an excellent choice for various industries such as food and beverage, cosmetics, electronics, and medical supplies.

4. Excellent Printability: Designed to accommodate various printing techniques, this film allows for high-quality graphics and branding elements to be applied seamlessly. Whether you require flexographic printing or digital printing capabilities, our Aluminum Coated OPP Film ensures that your designs are vibrant and eye-catching.

5. Eco-Friendly Options: We are committed to sustainability; therefore, our Aluminum Coated OPP Film can be produced with eco-friendly materials that comply with environmental regulations. This allows businesses to maintain their commitment to sustainability while still achieving superior packaging performance.

6. Durability and Strength: The inherent strength of OPP combined with the aluminum coating results in a film that is resistant to tearing and puncturing. This durability ensures that your products are protected during transportation and storage, reducing the risk of damage.

7. Customizable Solutions: Understanding that every business has unique requirements, we offer customizable options for thickness, width, and roll sizes. Our team works closely with clients to develop tailored solutions that meet specific packaging needs while adhering to industry standards.

Conclusion:

Our Aluminum Coated OPP Film is available for bulk buy, allowing businesses to take advantage of competitive wholesale pricing. This film is perfect for manufacturers looking to enhance their product packaging while ensuring durability and aesthetic appeal. With its reflective surface, the aluminum coating not only adds a touch of elegance but also improves the shelf life of packaged goods by protecting them from external elements.

As an established exporter in the packaging industry, we understand the importance of reliable supply chains. Our commitment to excellence ensures that our clients receive consistent quality with every order. We offer OEM services tailored to your specific requirements, allowing you to customize the film according to your branding needs.

When you choose our Aluminum Coated OPP Film, you benefit from bulk prices that make it an economical choice for large-scale operations. Whether you are a small business or a large manufacturer, our competitive pricing structure ensures that you can maintain profitability while providing top-notch packaging solutions.

Partner with us today and experience the difference that comes from working with a trusted manufacturer and supplier in the industry. Our dedicated team is here to assist you with any inquiries regarding bulk orders or customization options. Elevate your packaging strategy with our Aluminum Coated OPP Film—where quality meets affordability in every roll.