What Are Metalized Films and How Are They Used in Thermal Insulation Applications?

When you investigate the use of metalized films in thermal insulation applications, the first thing to understand is what these films really are. A metalized film is a very thin plastic layer coated with a metallic film, often aluminum. This metal layer is applied using techniques like vacuum metallization or sputtering. The main goal is to get a shiny, reflective surface. This surface reflects heat and blocks moisture and oxygen, making the films highly useful for several industries.

What is a metalized film? Definition, composition, and common metallic coatings

Metalized films consist of a plastic base film, such as polypropylene, polyester (PET), or polyethylene, coated with a thin metal layer. Most commonly, aluminum is used because of its excellent reflective properties and cost-effectiveness.

| Component | Descripción |

|---|---|

| Base Film | Thin plastic layer, e.g., PET, polypropylene, or polyethylene |

| Metal Coating | Usually aluminum, sometimes copper or silver |

| Espesor | Metal layer about 1/200th the thickness of pure aluminum foil |

The metal coating gives these films metallic shine and thermal reflectivity. The thickness of the metal layer is very small but enough for heat reflection and barrier performance.

Types of metalized films used in thermal insulation

There are several common types of metalized films made from different plastic bases, each with unique properties:

- Aluminum metallized film: High barrier against moisture and oxygen. Common in food packaging and insulation.

- Vacuum metallized film: Uniform metal coating via vacuum process. Good for optical clarity and smooth finish.

- Metallized polypropylene: Moisture resistant, strong, and heat sealable. Used in packaging.

- Polyester (PET) metallized film: Strong mechanical properties, good moisture and gas barrier, used in electronics and packaging.

- Polyethylene metallized film: Budget-friendly, moisture barrier but lower mechanical strength.

Each type suits different insulation needs, with varying durability, barrier properties, and costs.

How do metalized films provide thermal insulation? Reflective properties and barrier mechanisms

The main way metalized films insulate is by reflecting radiant heat. The thin metal layer reflects up to 94% of infrared radiation, preventing heat transfer between environments. This reflective layer works like a mirror for heat, sending thermal energy back where it came from.

Beyond reflection, these films act as excellent barriers against oxygen, moisture, and light. Blocking moisture and oxygen helps keep materials insulated by stopping heat loss due to condensation or corrosion.

Key ways metalized films provide insulation:

- Reflect radiant heat: Shiny metal surface reflects heat waves, reducing heat transfer.

- Block gases and moisture: Thin metal coating acts as a barrier to moisture and oxygen.

- Prevent light penetration: Limits heat gains from solar infrared rays.

- Add mechanical layer: Base plastic film adds strength and protects metal layer.

This dual role as thermal reflector and barrier makes metalized films valuable in insulation.

Differences in thermal insulating capabilities between metalized films and pure aluminum radiant barriers

Metalized films and pure aluminum radiant barriers both reflect heat, but their performance differs because of metal layer quality and thickness.

| Feature | Metalized Films | Pure Aluminum Radiant Barriers |

|---|---|---|

| Reflectividad | ~94% | ~97% |

| Metal layer thickness | Very thin (~1/200th aluminum foil) | Thick, nearly pure aluminum foil |

| Oxidation resistance | Lower, metal layer prone to degrade | Higher, oxide layer protects metal |

| Durability | Lower, vulnerable to wear and handling | Higher, strong and long-lasting |

| Coste | Lower, cost-effective for volume | Higher, premium applications |

Pure aluminum foil barriers offer better durability and slightly higher reflectivity. They resist oxidation with a protective oxide layer that does not lower reflective power. Metalized films trade some durability for flexibility and lower cost.

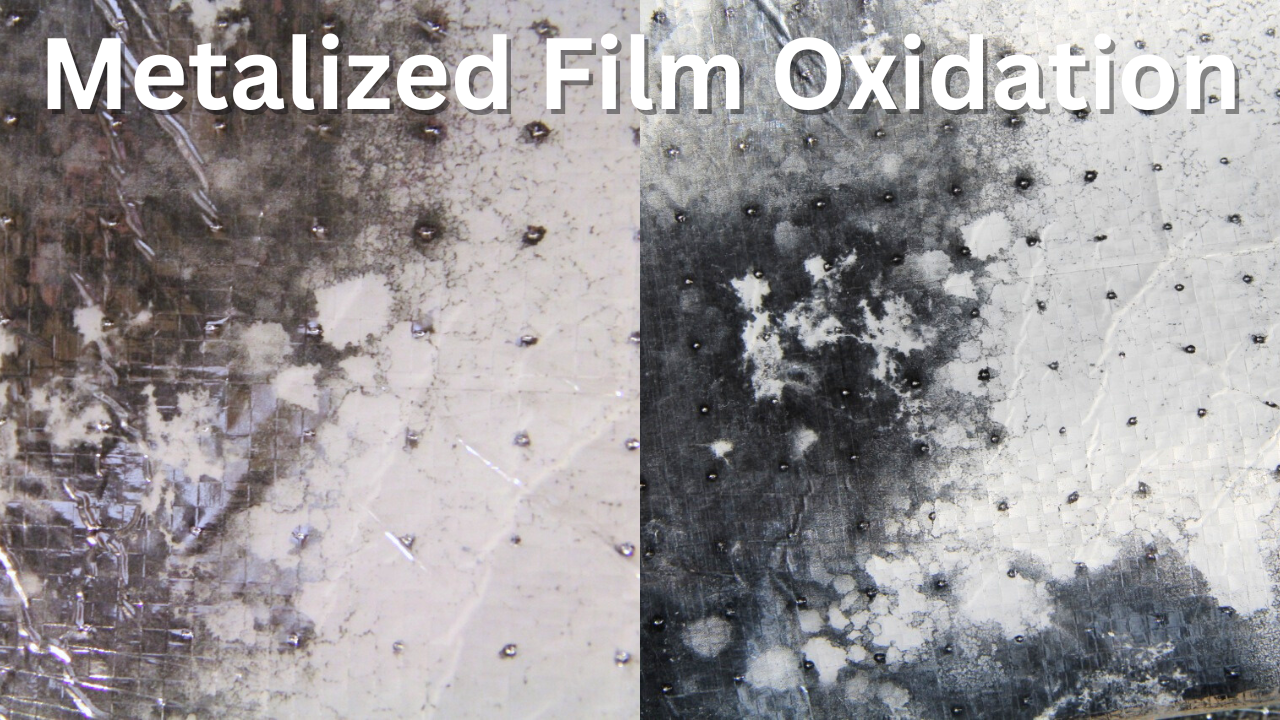

How does the thin metallic layer’s oxidation and durability affect thermal performance?

The thin metal layer on metalized films is fragile. Oxidation (reaction with oxygen) damages this layer over time, reducing reflectivity and thermal insulation.

- Metalized films have a thin aluminum layer on plastic, very vulnerable to oxidation.

- Oxidation forms aluminum oxide, which is usually transparent in thicker aluminum foils.

- However, in metalized films, oxidation can quickly degrade the thin metal layer.

- Perforations or damage allow moisture and air to reach metal faster, accelerating degradation.

- Tear resistance in films does not prevent issues from folding or handling damage.

This means metalized films may lose thermal insulation effectiveness faster than pure aluminum foil barriers. Proper handling and high-quality coatings are key to maximizing lifetime thermal performance.

What role do metalized films play in combining thermal insulation with barrier protection against oxygen, moisture, and light?

One major benefit of metalized films is their ability to double as thermal insulators and protective barriers. They keep out oxygen and moisture, which can cause spoilage or corrosion. They also block harmful UV and visible light.

This barrier function is crucial in applications like:

- Food packaging: Keeps food fresh by blocking oxygen and moisture.

- Pharmaceuticals: Prevents degradation of sensitive drugs.

- Electronics: Protects components from moisture and light.

The barrier properties come mainly from the metal coating, while the base plastic adds mechanical strength and flexibility. Together, they create a multi-functional film perfect for packaging and insulation.

What are the limitations and challenges of using metalized films for thermal insulation, including handling and longevity issues?

Despite advantages, metalized films come with challenges:

- Fragile metal layer: Thin metal layers are prone to oxidation and damage.

- Handling issues: Films are flexible but hard to lay flat permanently, making installation tricky.

- Longevity concerns: Thermal performance declines over time due to metal degradation.

- Perforation risk: Holes or tears drastically reduce barrier and reflective qualities.

- Adhesion: Metal layer adhesion to plastic affects durability.

Due to these factors, metalized films may not last as long as more rigid insulation materials. For long-term radiant heat barriers, pure aluminum foil often performs better.

However, metalized films excel in applications needing lightweight, flexible, and cost-effective thermal barriers with good moisture and gas blocking. When carefully processed and installed, they offer a balanced combination of thermal, barrier, and aesthetic benefits.

By understanding what metalized films are and how they work, you can see their strong value in thermal insulation. You get reflective heat barriers combined with oxygen and moisture protection, all in a lightweight, flexible package. Just keep in mind their durability limits and how oxidation affects their performance over time. This insight helps choose the right film type for your insulation needs.

How Do Metalized Films Perform Across Different Thermal Insulation Applications and Industries?

When I investigate the use of metalized films in thermal insulation applications, I see their impact spans multiple industries—from buildings to electronics. Metalized films are thin plastic films coated with a very thin metal layer, usually aluminum. This metal layer creates a shiny surface that reflects heat and blocks moisture, oxygen, and light. Their lightweight and versatile nature allow these films to solve insulation challenges across fields.

Metalized Films in Building and HVAC Thermal Insulation

Metalized films play a key role in building and HVAC insulation. They are often applied in roofs, walls, and attics as radiant heat barriers. These films reflect a large portion of radiant heat, reducing heat flow into or out of buildings. This lowers the need for heating and cooling, saving energy and reducing bills.

A notable fact is that metalized film barriers achieve about 94% reflectivity, slightly less than pure aluminum radiant barriers that reflect 97% heat. However, metalized films offer advantages like flexibility and lower cost. Using them in insulation blankets, foam boards, and bubble wraps helps maintain indoor comfort and improves energy efficiency.

HVAC ducts also benefit from metalized films. Wrapping ductwork with these films reduces heat loss or gain during air transport. This improves system efficiency and helps maintain set temperatures.

Role of Metalized Films as Radiant Heat Barriers in Roofs, Walls, and Attics

Radiant heat barriers work by reflecting infrared radiation that transfers heat by radiation. Metalized films reflect this radiant heat before it enters living spaces. They are installed under roof sheathing, inside attics, or behind wall panels.

However, metalized films have a thin aluminum layer—about 1/200th the thickness of pure aluminum foil—making them prone to oxidation once the protective coating breaks. Oxidation reduces reflectivity, but pure aluminum radiant barriers resist degradation better due to a protective oxide layer that is clear and thin.

This means metalized films must be carefully handled and installed flat to avoid punctures or holes that let moisture in. Despite this, metalized films are popular for their cost-effectiveness, ease of installation, and ability to improve building energy performance.

Thermal Management in Automotive Applications

The automotive industry uses metalized films for more than just thermal insulation. These films help manage:

- Heat insulation: Reflect heat to keep vehicle interiors cooler, reducing air conditioner load and improving fuel efficiency by up to 5%.

- Sound insulation: Damp and block unwanted sounds for a quieter ride.

- Electromagnetic interference (EMI) shielding: Protect onboard electronics from radio-frequency interference and static electricity.

These films are often laminated or combined with foam layers to provide multipurpose insulation. Their lightweight nature supports vehicle weight reduction, further boosting fuel economy and reducing carbon emissions.

The rapid growth of the automotive market, with a 3.5% CAGR globally, especially in emerging markets like China and India, drives demand for advanced metalized films. Manufacturers now partner with material science firms to innovate multi-layer films that last longer and perform better.

Benefits of Metalized Films in Food Packaging Thermal Insulation and Barrier Protection

In food packaging, metalized films keep products fresh and safe. The aluminum coating provides a near-impermeable barrier against oxygen and moisture, which causes spoilage.

Key benefits include:

- Extended shelf life: Prevents oxygen and moisture entry to slow rancidity and spoilage.

- Light protection: Blocks UV rays or ambient light that degrade food quality.

- Clean heat sealing: Enables airtight packaging to preserve freshness.

- Visual appeal: Shiny metallic surfaces catch consumers’ eyes and support brand identity.

Metalized films like metallized polypropylene or polyester offer moisture resistance and durability suited for snacks, coffee, frozen foods, and confectionery packaging. The films’ barrier and insulation properties help reduce food waste and lower energy costs in cold chain logistics.

Enhancing Thermal Protection and Electrical Insulation in Electronics

Metalized films also excel in electronics for thermal management and electrical protection. Semi metallized PET films provide:

- Thermal insulation: Protect components from heat buildup, enhancing device lifespan.

- EMI shielding: Reflect and absorb unwanted electromagnetic waves that interfere with signal transmission.

- Electrostatic discharge (ESD) protection: Conduct static charge away safely to prevent damage.

- Electrical insulation: Dielectric properties useful in capacitors and transformers.

These films balance conductivity and barrier performance, making them vital in circuit boards, flexible displays, and packaging for sensitive electronics.

Real-World Case Studies Demonstrating Effectiveness

Case Study 1: Residential Attic Insulation in Texas

A study evaluated metalized film radiant barriers installed under roof sheathing in hot climates. Homes experienced a 10-15% reduction in summer cooling load, translating to significant energy savings over time.

Case Study 2: Automotive Thermal Film Application

An automaker used metalized multi-layer films in door panels and dashboards. They found a 5% fuel efficiency increase due to reduced air conditioning use and improved passenger thermal comfort.

Case Study 3: Food Packaging Shelf Life

A snack company switched from foil to metallized polypropylene film. Shelf life improved by 50%, and packaging costs dropped by 20%, helping reduce waste and boost profitability.

Design Trends Impacting Metalized Film Usage

In 2023, the design of metalized films reflects customer demand for aesthetics and sustainability:

- Bold metallic colors: Copper, gold, silver, and rose gold offer premium looks.

- Geometric patterns: Create a modern feel for packaging and building facades.

- Tech-inspired graphics: Appeal to innovation-minded consumers.

- Natural elements: Plants and textures communicate eco-friendliness.

- Minimalist typography: Enhances clarity and elegance.

These trends influence industries from food packaging to building insulation, where metalized films serve both functional and decorative roles.

Summary Table of Metalized Film Applications

| Industria | Use Case | Main Benefits |

|---|---|---|

| Building & HVAC | Radiant barriers, duct wrap | Energy savings, indoor comfort improvement |

| Automoción | Thermal, sound, EMI insulation | Fuel efficiency, noise reduction, electronics protection |

| Envasado de alimentos | Barrier film, freshness preservation | Extended shelf life, visual appeal, moisture and oxygen barrier |

| Electrónica | EMI shielding, electrostatic protection | Device safety, thermal management, signal clarity |

| Others | Labeling, signage, decorative architectural | Visual impact, durability |

Common Thermal Insulation Applications of Metalized Films

Metalized films find common use in insulating environments where heat reflection and barrier protection are vital. They are applied in:

- Roof and attic insulation to reduce summer heat gain.

- Wall insulation panels for better thermal regulation.

- HVAC systems for duct wrapping and lining.

- Automotive interiors for keeping vehicles cooler and quieter.

- Food packaging for preserving freshness and security.

- Electronic components needing EMI shielding and static protection.

How Metalized Films Improve Energy Efficiency in Buildings and Vehicles

The reflective quality of metalized films lowers radiant heat transfer. In buildings, this reduces cooling and heating energy. In vehicles, it lowers the air conditioning load and stabilizes cabin temperature. These savings contribute to overall reduced energy consumption and cut greenhouse gas emissions.

Industries Benefiting Most

Industries benefiting most from metalized film thermal insulation include:

- Construction and building management.

- Automotive manufacturing and aftermarkets.

- Food and beverage packaging.

- Electronics and electrical engineering.

- Pharmaceuticals and chemical packaging for protection.

Each sector leverages metalized films to balance function, cost, and design expectations efficiently.

What Are the Latest Trends, Advances, and Market Insights on Metalized Films for Thermal Insulation?

When you investigate the use of metalized films in thermal insulation applications, you quickly see how much progress has been made. Let's dive into the latest advances, market trends, and innovations shaping the future of these films.

Recent Technological Advancements Improving Thermal Insulation Performance

In the past few years, the thermal insulation performance of metalized films has improved a lot thanks to new technologies. One big step is the development of multi-layered metalized films. These films combine several layers of different materials with thin metallic coatings, usually aluminum. The result is films that reflect more heat, resist wear better, and last longer.

Another exciting innovation is smart films. These films change their reflectivity depending on temperature or light. For example, some smart metalized films darken when it's cold to keep heat in, and reflect heat when it's hot, to keep things cool. This dynamic response helps in reducing energy use even more than regular films.

Also, semi metallized PET films, coated through vacuum metallization, are gaining popularity. They offer strong moisture and oxygen barriers while remaining cost-effective and flexible. Their electrical conductivity adds value in electronic applications, while their reflectivity boosts thermal insulation.

Impact of Manufacturing Processes on Durability and Reflectivity

Manufacturing breakthroughs directly affect how metalized films perform. New vacuum metallization techniques produce ultra-thin, uniform aluminum layers on plastic substrates, improving reflectivity up to 94%, near the 97% of pure aluminum foils. Although pure aluminum maintains reflectivity longer due to its thicker metal layer and protective oxide, advances in coating control have made metalized films more durable.

Additionally, multi-layer lamination improves tear resistance and handling. Older metalized films were hard to lay flat and could easily degrade with moisture exposure. New processes now produce films that resist oxidation better by minimizing perforations and moisture entry.

Simpler application methods, like improved adhesives and easier heat-sealing, help installers work faster with less waste. This matters especially in large building projects or automotive manufacturing where speed and precision are key.

Growing Market Outlook in Automotive and Building Sectors

The market for metalized films in thermal insulation is expanding quickly. The global automotive sector alone shows nearly 3.5% annual growth, especially due to rising demand in China and India. Metalized films help vehicles keep interiors cooler by reflecting solar heat, reducing air conditioning load and boosting fuel efficiency by up to 5%. They also reduce noise and protect electronics from interference, increasing passenger comfort and safety.

In the building and construction sector, metalized films are used in roofs, walls, and HVAC systems as radiant heat barriers. They reduce heat transfer, improving energy efficiency and helping buildings meet stricter energy codes. The push for green construction fuels this trend. These films help cut heating and cooling costs while increasing indoor comfort.

Altogether, metalized films are vital for energy-efficient solutions across industries.

Role of Strategic Partnerships and Government Incentives

Strategic partnerships between automotive manufacturers, insulation producers, and material science firms have accelerated new product development. These collaborations combine expert knowledge and share costs, speeding innovation.

Governments also boost this field with subsidies and research grants targeting energy saving and sustainable materials. For example, incentives supporting building insulation upgrades include metalized films as part of financing packages. These policies increase adoption rates and encourage companies to invest in better products.

Environmental and Energy-Saving Benefits Supporting Sustainability

Metalized films play a key role in reducing energy consumption. Their reflective layers send up to 94% of radiant heat back, reducing the load on air conditioning in cars and buildings. This lowers fossil fuel use and greenhouse gas emissions.

Using metalized films also supports the circular economy. They extend product life by protecting contents from moisture and oxygen, reducing food waste and product spoilage in packaging. Plus, new films often use recyclable substrates, aiding waste reduction.

Smart Technology Integration Enhancing Dynamic Thermal Management

Smart metalized films represent the frontier of thermal insulation innovation. These films contain layers that change optical properties dynamically. For example, thermochromic coatings adjust reflectance based on heat, while electrochromic films switch reflectivity when powered using tiny electric signals.

This means heat reflection isn’t fixed but adapts to outside conditions or user needs. Vehicles equipped with smart films can automatically keep cabin temperature stable with less battery drain. Buildings use these films in windows or walls to balance heating and cooling loads as seasons change.

Economic Impacts and Job Opportunities in Metalized Films Industry

The boom in metalized films for thermal insulation boosts many job sectors. Research and development teams innovate new materials and processes. Manufacturing facilities grow to meet demand, creating factory jobs. Installation and maintenance also need skilled workers, especially in automotive and construction.

Investment interest has surged, with companies merging or acquiring startups to hold strong market positions. This growth drives wages up and encourages STEM education to support the industry’s future.

Summary Table of Key Advances and Market Insights

| Area | Details |

|---|---|

| Technological Innovations | Multi-layered films; Smart thermochromic and electrochromic films; Semi metallized PET |

| Manufacturing Improvements | Vacuum metallization techniques; Better lamination; Enhanced oxidation resistance |

| Market Sectors | Automotive (3.5% CAGR, emerging markets); Building and HVAC (energy-efficiency push) |

| Strategic Drivers | Industry partnerships; Government incentives for sustainability and research |

| Beneficios medioambientales | Up to 94% heat reflectance; Reduced energy use and emissions; Supports circular economy |

| Smart Film Features | Dynamic heat reflection adapting to temperature and electricity inputs |

| Economic Impact | Job creation in R&D, manufacturing, installation; Increased investments and innovation |

What New Innovations Are Shaping the Future of Metalized Films?

You can expect continued improvements in multi-layer structures that combine different metals or polymers to fine-tune heat reflection and strength. Smart films will get smarter, with faster switching speeds and lower power consumption. New eco-friendly substrates will reduce environmental impact.

How Is the Market Evolving for Thermal Management Films?

The market is trending toward multifunctional films that combine insulation with electrical performance, like EMI shielding in automotive electronics. Growth in electric vehicles and green buildings also drives demand. Strategic mergers will continue to consolidate smaller niche players.

What Role Do Policies and Sustainability Play?

Policymakers push for better energy conservation, making metalized films essential components in future building codes and automotive standards. Sustainability efforts mean manufacturers focus on recyclable materials and reducing carbon footprints. This support opens funding and market access.

Investigate the use of metalized films in thermal insulation applications, and you’ll see an industry that's dynamic, innovative, and tied to larger trends in energy saving and sustainability. These films are no longer just shiny coatings — they're smart, efficient, and essential for a cooler, greener future.

Additional Data Table 1: Thermal Reflectivity Comparison Between Metals and Films

| Material | Reflectivity (%) | Typical Thickness | Durability |

|---|---|---|---|

| Pure Aluminum Foil | 97 | Thick (~microns to tens of microns) | Alta |

| Metalized Films (Aluminum) | 94 | Very thin (~1/200th aluminum foil) | Moderate to Low |

| Copper-Coated Films | ~88 | Thin | Moderate |

| Silver-Coated Films | ~95 | Thin | Low to Moderate |

Additional Data Table 2: Common Substrate Materials and Their Properties

| Substrate Material | Mechanical Strength | Moisture Barrier | Coste | Common Applications |

|---|---|---|---|---|

| Polyester (PET) | Alta | Alta | Medio | Electronics, Food Packaging |

| Polypropylene (PP) | Medio | Medio | Low-Medium | Food Packaging, Insulation |

| Polyethylene (PE) | Bajo | Medio | Bajo | Budget Packaging, Insulation |

These tables provide additional visualization of important thermal and material properties relevant to metalized films emphasizing their performance differences and typical usage contexts within thermal insulation and packaging.

FAQs about Investigate the use of metalized films in thermal insulation applications

What are metalized films and how are they composed?

Metalized films are very thin plastic layers coated with a thin metallic layer, most commonly aluminum, applied by techniques like vacuum metallization or sputtering, creating a shiny surface that reflects heat and blocks moisture and oxygen.

How do metalized films provide thermal insulation?

Metalized films provide thermal insulation primarily by reflecting up to 94% of infrared radiant heat, blocking moisture and oxygen to prevent heat loss, and adding mechanical strength with their plastic base layer.

What are the differences between metalized films and pure aluminum radiant barriers?

Metalized films have a very thin metal layer with about 94% reflectivity and lower durability due to oxidation risks, whereas pure aluminum radiant barriers have thicker metal layers, about 97% reflectivity, better oxidation resistance, and higher durability but at a greater cost.

In which industries are metalized films commonly used for thermal insulation?

Metalized films are widely used for thermal insulation in building HVAC systems, automotive thermal and sound insulation, food packaging to extend shelf life, and electronics for thermal management and EMI shielding.

What limitations should be considered when using metalized films for thermal insulation?

Metalized films face challenges such as fragile metal layers prone to oxidation, damage from handling, reduced reflectivity over time, risk of perforation that compromises insulation, and generally shorter lifespan compared to rigid aluminum foil barriers

Metalized films blend thin metal coatings with flexible plastics to block heat well. They serve many uses, from building insulation to food packaging and electronics. Their strength lies in reflecting radiant heat and blocking moisture and air. New technology boosts their durability and adds smart features for better thermal control. Although they face limits like oxidation and wear, their role grows as industries seek energy-saving, eco-friendly solutions. Understanding metalized films helps you choose the right material for your insulation needs with confidence.