Compare Different Types of Metalized Films Based on Applications and Properties: What Are the Main Variants and Their Material Characteristics?

Metalized films are flexible plastics coated with a thin metal layer, often aluminum. This metal layer offers reflectivity, barrier protection, and a shiny look. You see them in food wrappers, labels, and insulation materials. The metal coating is applied by vacuum metallization. In this process, metal is heated in a vacuum until it vaporizes. Then the metal vapor condenses onto a moving plastic film, creating a very thin, even layer. This thin metal layer usually accounts for about 1% of the total film thickness.

Common Types of Metalized Films in Industry

The metalized films market includes several main types:

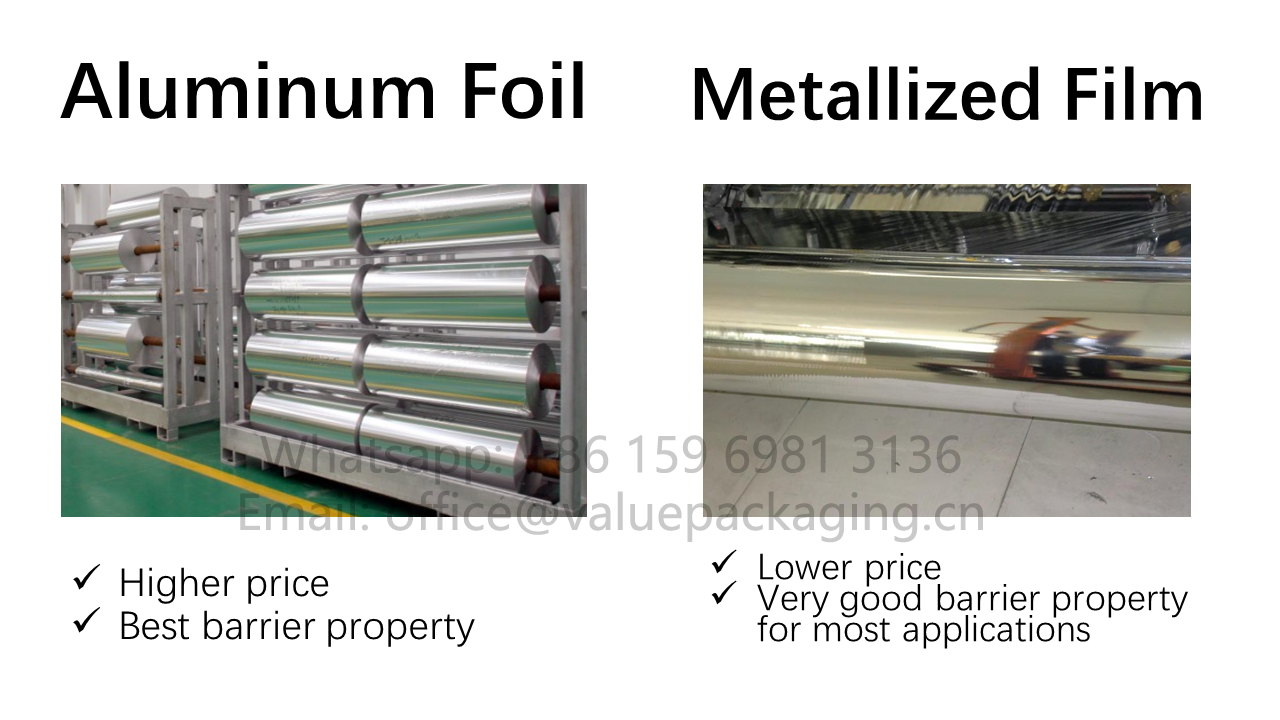

- Aluminum Foil: Made by rolling pure aluminum down to 12-20 microns thick. It is opaque, flexible, and offers an excellent barrier to moisture, oxygen, and light.

- Metallized PET Film: Polyethylene terephthalate (PET) film coated with about 99.98% pure aluminum via vacuum evaporation. It is transparent, lightweight, strong, and moderately good as a barrier.

- Metalized BOPP Film: Biaxially oriented polypropylene (BOPP) film with an aluminum coating. This film is flexible, strong, and offers moisture and oxygen resistance along with excellent printability.

- Oxo-Biodegradable Metalized Films: These contain additives that help the plastic break down when exposed to oxygen and sunlight over time. They are designed to reduce plastic pollution while maintaining functional packaging benefits.

- Metalized Cavitated White Opaque Films: These have a special microvoided structure making them bright white and opaque. They combine a metal layer with excellent barrier and a high optical density surface.

Core Material Properties of Each Metalized Film Type

Each metalized film type shows different traits based on its base polymer and metal type. Let’s look at the key properties:

| Film Type | Barrier Protection | Tensile Strength | Resistencia a la humedad | Optical Density | Imprimibilidad |

|---|---|---|---|---|---|

| Aluminum Foil | Excellent (full barrier) | High (rigid, flexible) | Excellent | Opaque, reflective | Poor alone (needs lamination) |

| Metalized PET Film | Moderate | High (strong polyester) | Good | Semi-transparent metallic | Good |

| Metalized BOPP Film | Good | Moderate (strong & flexible) | Very Good | High gloss metallic | Excellent (chemical treated) |

| Oxo-Biodegradable Films | Moderate | Moderate | Fair | Moderate | Good |

| Cavitated Opaque Films | Good | Moderate | Good | Very High (bright white) | Good |

Effects of Metal Types on Properties and Applications

Different metals in metalized films directly affect their performance and use:

- Aluminum: The most common, offering excellent moisture and oxygen barrier. Reflective and lightweight, ideal for food wrapping and insulation.

- Copper: Offers good thermal and electrical conductivity. Used mostly in electronics and decorative films, not common for food packaging.

- Silver: Highly reflective, key for solar control and insulation films. It has antimicrobial properties but is expensive.

- Zinc: Known for antimicrobial effects and UV resistance, useful in food packaging and agricultural films.

Aluminum remains king in packaging due to cost, barrier ability, and lightness.

Metalized Polyester (PET) vs. Metalized Polypropylene (BOPP) Films

Both PET and BOPP films get aluminum coatings but show key differences:

-

PET Metalized Film:

- Made from strong polyester, adding tensile strength.

- It has moderate moisture and oxygen barriers but is lighter and more flexible than foil.

- Semi-transparent metallic look.

- Suitable for coffee capsules, snack packaging, and pharmaceutical pouches.

- Good printability with flexography, UV, and offset printing inks.

-

BOPP Metalized Film:

- BOPP is polypropylene stretched biaxially, increasing toughness and flexibility.

- It offers very good moisture barrier, great gloss, and print quality.

- Surface chemically treated for superior ink adhesion.

- Widely used for snack bags, labels, and pharmaceutical packaging.

- Heat sealable surface allows easy packaging sealing.

Influence of Layer Structures: Monoweb vs. Multi-Layer Laminate

Metalized films come either as single-layer monowebs or part of multi-layer laminates.

- Monoweb: A single metalized film layer. Cost-effective and flexible but has limited barrier ability because the metal layer is thin and can have pinholes.

- Multi-layer Laminate: Films combined with others (like polyethylene or paper) in layers. This structure improves moisture and oxygen barrier performance dramatically. Laminates prevent metal layer damage, allow sealing, and boost mechanical strength.

For example, multi-layer laminates containing metalized PET with polyethylene sealing layers show excellent shelf life extension in food packaging by reducing moisture and oxygen ingress.

Environmental and Biodegradability Aspects of Oxo-Biodegradable Metalized Films

Oxo-biodegradable metalized films are an emerging choice for more eco-friendly packaging. These films use additives that cause plastic chains to break down when exposed to oxygen, heat, and light. Over months or years, this leads to fragmentation and microbial degradation.

- They retain barrier and mechanical properties during use, ensuring product safety.

- After disposal, oxo-biodegradable films reduce plastic pollution by accelerating breakdown compared to conventional plastics.

- These films still provide attractive metallic finish and compatibility with heat sealing and printing.

However, their breakdown depends on environmental conditions and time. They are a transitional solution in pursuit of full compostable bioplastics.

Metalized films serve many industries, from food and pharma packaging to electronics and insulation. Aluminum metal is most commonly used for its barrier and reflectivity. BOPP and PET are the main base polymers, chosen based on strength, flexibility, and printing needs. Layer structures and metal types tailor films for specific applications. Advances like oxo-biodegradable metalized films offer more sustainable options. Understanding these differences helps choose the best metalized film variant to meet your product’s protection, appearance, and environmental goals.

Table: Summary Comparison of Metalized Film Types by Properties and Applications

| Film Type | Aplicaciones | Barrier Level | Appearance | Environmental Aspect |

|---|---|---|---|---|

| Aluminum Foil | Food wrapping, insulation, pharma | Excellent | Opaque, reflective | Low biodegradability, recyclable but heavier |

| Metalized PET Film | Snack bags, coffee capsules, pharma | Moderate | Semi-transparent metallic | Recyclable, lighter than foil |

| Metalized BOPP Film | Labels, snack bags, pharma | Good | High gloss metallic | Chemically treated; recyclable with care |

| Oxo-Biodegradable Films | Eco-friendly packaging | Moderate | Moderate metallic | Biodegradable additives enhance breakdown |

| Cavitated Opaque Films | Bright white packaging requiring opacity | Good | Very high optical density | Similar recycling challenges as other films |

How Do Metalized Films Perform Across Various Applications and Industries?

Metalized films have become key players in many industries due to their unique blend of strength, barrier protection, and visual appeal. When you compare different types of metalized films based on applications and properties, you’ll see how versatile and valuable they are. Let’s dive deeper into their roles in packaging, electronics, agriculture, and more.

Enhancing Packaging in Food, Pharmaceuticals, and Cosmetics

In the food industry, metalized films serve as excellent barriers against moisture, oxygen, and light. These are key factors that spoil freshness and degrade food quality. For example, snack packs and bakery products often use metalized biaxially oriented polypropylene (BOPP) or metalized polyester (PET) films. These films not only keep the contents fresh but also allow high-quality, vibrant printing to attract customers. This is critical in competitive markets.

In the pharmaceutical sector, metalized films help packages remain sterile and secure. They block contaminants like bacteria, dust, and oxygen, which could affect medicine potency. For cosmetics, the shiny metallic look enhances brand appeal on shelves. Metalized films add a premium feel, often used in pouches or tubes for creams and lotions.

Extending Shelf Life and Preserving Freshness

The core benefit of metalized films lies in their barrier properties. A thin aluminum layer deposited onto plastic films makes an almost airtight shield. This cuts down exposure to air and moisture, key enemies of freshness.

Metalized barrier films are frequently solvent-free coated, making them safe for direct contact with food. They reduce food waste by extending shelf life—important in reducing costs and environmental impact.

Performance facts:

- Multilayer laminates with metalized films boost oxygen and moisture barrier levels.

- Metalized films are compatible with heat sealing, ensuring tight package closure.

- In India, the growing trend of hygiene-conscious consumers drives a 26.7% CAGR growth in metalized film packaging.

Benefits in Electronics and Reflective Insulation

In electronics, metalized films protect sensitive components. For example, aluminized PET films act as insulating layers or wraps for batteries and circuit boards. These films keep existing heat and electromagnetic interference in check.

Reflective insulation applications use metalized films to bounce back heat. Buildings, vehicles, and solar panels benefit from this high reflectivity. Silver and aluminum coatings reflect infrared rays, improving energy efficiency.

Metalized Wrap-Around Label Films in Beverage Packaging

Major beverage brands use metalized wrap-around label films for branding and protection. These films are typically BOPP, metalized on one side and coated for heat seal on the other. Their attributes include:

- High optical density for enhanced metallic appearance.

- Stiffness needed for label durability.

- Mold resistance to keep packages fresh and attractive.

This helps beverages stand out on shelves while guarding against moisture and product contamination.

Decorative Laminates for Automotive and Furniture Industries

Metalized films also shine in decorative laminates. They enhance automotive interiors and furniture with:

- Aesthetic value due to their metallic, shiny finish.

- Durable surfaces that resist scratches and wear.

- Lightweight alternatives to metal parts.

Manufacturers prefer metalized laminates for their balance of beauty, strength, and cost-effectiveness.

Agricultural Uses: Greenhouse Covers and Mulch Films

In agriculture, metalized films have practical roles:

- Greenhouse covers: Reflect UV rays and heat to aid plant growth.

- Mulch films: Help regulate soil temperature, conserve moisture, and suppress weeds.

For example, zinc metalized films add anti-microbial properties, reducing soil-borne diseases. This extends crop yields and farm profitability.

Compatibility with Packaging Machines Like HFFS and VFFS

Metalized films are engineered for seamless use on packaging lines, especially:

- HFFS (Horizontal Form Fill Seal) machines.

- VFFS (Vertical Form Fill Seal) machines.

Films like metalized BOPP and PET support fast packaging speeds. Their heat-sealable coatings provide secure seals without equipment clogging. This reduces downtime and improves production efficiency.

Key Performance Benchmarks for Metalized Films

When comparing different metalized films, here are standard performance markers:

| Propiedad | What It Means | Why It Matters |

|---|---|---|

| Durability | Resistance to tears, punctures | Prevents damage during shipping |

| Imprimibilidad | Quality of ink adhesion and clarity | Supports branding and labeling |

| Heat-Seal Strength | Ability to form tight, secure seals | Maintains package integrity |

| Moisture Barrier | Stops dampness entering/exiting package | Keeps product dry and fresh |

| Oxygen Barrier | Limits air penetration | Extends shelf life |

| Optical Density | Measure of film's metallic shine | Enhances visual appeal |

Table: Industry Applications and Metalized Film Attributes

| Industria | Film Requirements | Typical Metalized Film Type | Key Benefit |

|---|---|---|---|

| Food & Pharma | High barrier, heat seal, printability | Metalized PET, Metalized BOPP | Extended shelf life, safety |

| Electrónica | Insulation, EMI shielding | Aluminum metalized PET | Component protection |

| Cosmetics | Glossy appearance, chemical resistance | Metalized BOPP | Premium packaging look |

| Agricultura | UV protection, antimicrobial properties | Zinc metalized films | Crop protection and yield |

| Automoción | Scratch resistance, aesthetic laminates | Metalized decorative laminates | Durable and visually appealing |

What Are the Advantages, Limitations, and Selection Criteria for Different Metalized Films?

When you compare different types of metalized films based on applications and properties, you find distinct advantages and some limitations. Picking the right metalized film impacts product protection, brand appeal, cost, and sustainability.

Primary Advantages of Metalized Films Compared to Traditional Packaging

Metalized films bring major benefits over classic materials like aluminum foil, glass, or paper. Here’s why many industries favor metalized films:

- Excellent Barrier Properties: Metalized films block oxygen, moisture, and light well. This barrier extends shelf life—especially in food, pharmaceuticals, and cosmetics—by slowing spoilage and contamination.

- Lightweight and Flexible: Unlike glass or thick aluminum, metalized films are very light and flexible. This lowers shipping costs and reduces breakage risks.

- High Optical Appeal: The metallic coating gives a shiny, bright finish. This makes packaging more eye-catching and helps brands stand out on shelves.

- Compatibility with Packaging Machines: Metalized films work well with high-speed machines like HFFS and VFFS. They can be used as single webs or laminates.

- Cost-Effectiveness: These films use a very thin metal layer—usually aluminum vacuum-deposited—only about 1% of the metal in foil. This cuts material cost significantly.

- Thermal Insulation: Metal layers reflect heat, useful in insulation and solar control products.

These advantages make metalized films a popular choice across sectors like snacks, beverages, pharmaceuticals, and agriculture.

Limitations and Challenges of Metalized Films

Despite their perks, metalized films have some limits you need to consider:

| Limitation | Explanation |

|---|---|

| Lower Barrier Than Foil | Metalized films don’t fully block gases and moisture as well as aluminum foil, so they may not suit ultra-sensitive products. |

| Susceptible to Scratches | The thin metal layer can scratch, damaging barrier or optical properties. |

| Limited Heat Resistance | Some metalized films can lose performance or deform at high sealing or processing temperatures. |

| Recycling Complexity | Films laminated with multiple layers or plastics can be hard to recycle compared to single-material foil or glass. |

| Chemical Sensitivity | Films may interact with acidic or salty contents that foil better resists. |

Knowing these issues helps define applications where metalized films will perform best versus alternatives.

Cost Comparison with Aluminum Foil and Glass

Metalized films are usually more cost-effective in terms of material and total packaging costs:

- Material Use: Metalized films use ~1% of the metal in aluminum foil by weight, dramatically reducing raw material costs.

- Lower Weight: Lighter weight means lower transportation costs and handling savings.

- Machinery Compatibility: Their flexibility reduces packaging machine downtime and waste.

- Production Cost: Vacuum metallization adds costs but still usually keeps films cheaper than foil laminates or glass containers.

Glass bottles offer excellent product protection and recyclability but come with high freight and breakage costs. Aluminum foil provides the best barrier but at a higher packaging cost and less flexibility.

Factors to Consider When Selecting Metalized Films

Choosing the ideal metalized film depends on the product needs, performance, and budget. Key factors:

- Barrier Requirements: What level of moisture, oxygen, and light protection does the product need? Food products with a long shelf life require stronger barriers.

- Optical Appeal: Should the packaging be bright, shiny, or opaque? Labels and brand look are critical for consumer products.

- Mechanical Strength: Films must resist tearing, punctures, or heat during packaging and shipping.

- Compatibility with Packaging Machines: The film should work smoothly with existing machinery.

- Environmental Impact: Consider recyclability, waste reduction, and carbon footprint.

- Product Sensitivity: Films interact differently with moisture, oils, or chemicals.

- Sealing and Heat Resistance: Ensure the film seals properly and tolerates processing temperatures.

Table: Metalized Film Selection Criteria Compared to Application Needs

| Criteria | Envasado de alimentos | Productos farmacéuticos | Electrónica | Decorative Use | Agricultura |

|---|---|---|---|---|---|

| Barrier | Alta | Very High | Medio | Bajo | Medio |

| Optical Appeal | Alta | Medio | Bajo | Very High | Bajo |

| Mechanical Strength | Medio | Alta | Alta | Medio | Alta |

| Resistencia al calor | Medio | Alta | Medio | Bajo | Medio |

| Sustainability | Medio | Alta | Medio | Medio | Alta |

How Barrier, Optical Appeal, Mechanical Strength, and Environmental Impact Affect Choice

- Propiedades de barrera dictate how well a film protects contents. For example, metalized polyester films offer strong moisture and oxygen resistance, ideal for snacks or medicines.

- Optical Appeal helps products get noticed. Films like metalized cavitated white opaque provide a bright white look beneath the metal layer, boosting print quality.

- Mechanical Strength ensures films survive packaging stress without tears or holes. BOPP metalized films offer excellent stiffness and puncture resistance.

- Environmental Impact concerns grow fast. Oxo-biodegradable metalized films support waste reduction but face scrutiny on effective biodegradation and recycling.

Balancing these aspects depends on your product’s demands and company goals.

Recent Design Trends Impacting Metalized Film Appearance and Branding

In 2023, packaging design on metalized films follows exciting trends that boost brand identity:

- Use of bold metallic colors such as rose gold, copper, and silver.

- Geometric patterns and futuristic looks reflect tech and innovation.

- Natural elements like flowers and leaves combine nature with metal shine.

- Minimalist typography against opaque or high-gloss backgrounds.

- Combination of matte and gloss finishes for tactile appeal.

These trends show how metalized films help brands tell stories visually.

How Metalized Films Support Sustainability and Carbon Footprint Reduction

Metalized films can advance sustainability in several ways:

- Lightweight Packaging: Lower transport weight reduces CO2 emissions.

- Longer Shelf Life: Prevents food spoilage and waste.

- Material Efficiency: Thin metal layers use fewer resources than foil or glass.

- Possible Oxo-Biodegradable Films: Offer partial biodegradability, reducing plastic persistence.

- Recyclability Potential: Single-material metalized films are easier to recycle than complex laminates.

India’s metalized film packaging market is growing rapidly, driven partly by sustainability goals and hygiene concerns post-pandemic.

Practical Recommendations for Industry Professionals

To pick the best metalized film type:

- Identify Application Needs: Match barrier, appearance, and strength to product and shelf life.

- Assess Machine Compatibility: Verify heat sealing and packaging method suitability.

- Balance Cost and Performance: Compare total costs, including materials, processing, and waste.

- Check Environmental Policies: Use recyclable or biodegradable films where possible.

- Follow Design Trends: Use film finishes to enhance brand appeal.

- Test Film Samples: Trial metalized films in real packaging lines for performance validation.

With these steps, you’ll find the metalized film variant that fits your product, protects it, and supports your brand and sustainability efforts.

This comprehensive look covers metalized films advantages, limitations, cost-effectiveness, and selection criteria. Understanding these helps you make smart choices to meet your packaging needs.

FAQs about Compare Different Types of Metalized Films Based on Applications and Properties:

What are the main types of metalized films and their material characteristics?

The main types of metalized films include aluminum foil, metalized PET film, metalized BOPP film, oxo-biodegradable metalized films, and metalized cavitated white opaque films, each differing in barrier protection, tensile strength, moisture resistance, optical density, and printability.

How do metal types affect the properties and applications of metalized films?

Metal types influence performance with aluminum providing excellent moisture and oxygen barriers and reflectivity for food packaging, copper offering thermal and electrical conductivity for electronics, silver delivering high reflectivity and antimicrobial properties, and zinc adding antimicrobial effects and UV resistance for agricultural uses.

What are the advantages of metalized films compared to traditional packaging?

Metalized films offer excellent barrier properties, lightweight flexibility, high optical appeal, compatibility with high-speed packaging machines, cost-effectiveness due to a thin metal layer, and thermal insulation, making them preferred in food, pharmaceuticals, cosmetics, and other sectors.

What limitations should be considered when using metalized films?

Limitations include lower barrier performance than aluminum foil, susceptibility to scratches, limited heat resistance, recycling challenges due to multilayer structures, and potential chemical sensitivity compared to foil.

How does the choice between metalized PET and BOPP films influence packaging applications?

Metalized PET films provide high tensile strength, moderate barriers,

We explored key metalized film types, their materials, and main features. I broke down how metals impact performance and compared popular PET and BOPP films. Then, I covered their uses from food packaging to automotive laminates. Finally, I shared pros, cons, and smart tips for choosing the right film. Metalized films offer strong protection and branding options, but you must weigh costs and eco-factors. With this overview, you can pick the film that fits your needs well, boosting product life and style.