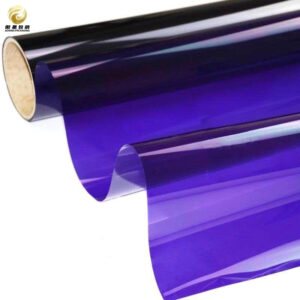

Película aluminizada

| Producto | Película OPP metalizada |

| Material | OPP + color+ capa de aluminio / OPP + aluminio + capa de color |

| Espesor | 15um;18um |

| Opción de color | Rojo, azul, púrpura, verde, oro, amarillo, rosa, arco iris, etc. |

| Anchura y longitud | Anchura:500~1800mm Longitud:Personalizada |

Descripciones detalladas

Product Description: Aluminumized Film

Overview: Aluminumized film is a versatile and innovative material that combines the lightweight properties of plastic films with the reflective qualities of aluminum. This unique composite film is engineered to provide exceptional performance across a wide range of applications, making it an ideal choice for industries such as packaging, insulation, agriculture, and more.

Key Features:

1. Superior Reflectivity: The aluminum layer in aluminumized film offers outstanding reflectivity, effectively bouncing back heat and light. This characteristic makes it an excellent choice for thermal insulation applications, helping to maintain temperature stability in various environments.

2. Lightweight and Durable: Despite its thin profile, aluminumized film boasts remarkable strength and durability. Its lightweight nature facilitates easy handling and application, while its robust construction ensures longevity even in demanding conditions.

3. Moisture and Gas Barrier: Aluminumized film provides an effective barrier against moisture and gases, making it suitable for food packaging and preservation. This feature helps extend the shelf life of products by preventing spoilage and maintaining freshness.

4. UV Protection: The reflective properties of aluminumized film also extend to ultraviolet (UV) radiation protection. This makes it an ideal choice for agricultural applications, where it can shield crops from harmful UV rays while promoting optimal growth conditions.

5. Versatile Applications: Aluminumized film is utilized in a myriad of applications, including: – Packaging: Ideal for food products, pharmaceuticals, and consumer goods due to its barrier properties. – Insulation: Used in building materials to enhance energy efficiency by reflecting heat. – Agriculture: Employed as mulch films to regulate soil temperature and moisture levels. – Decorative Uses: Its shiny surface lends itself well to decorative applications in crafts and design.

6. Eco-Friendly Options: Many manufacturers are now producing aluminumized films using recyclable materials or processes that minimize environmental impact. This commitment to sustainability allows businesses to meet eco-conscious consumer demands without compromising on quality or performance.

Conclusion:

As a leading producer and supplier of Aluminumized Film, we pride ourselves on delivering products that adhere to the highest quality standards. Our manufacturing process utilizes advanced technology and rigorous quality control measures to ensure that each roll of film meets the specific requirements of our clients. Whether you are looking for a reliable manufacturer for your packaging solutions or an exporter to facilitate international trade, we are equipped to meet your needs.

We offer competitive bulk prices for businesses looking to bulk buy Aluminumized Film. Our wholesale options are designed to provide cost-effective solutions without compromising on quality. As an OEM (Original Equipment Manufacturer), we also cater to custom specifications, allowing you to tailor the product according to your unique requirements.

Our commitment to excellence has established us as a trusted partner in the industry. We understand the importance of timely delivery and customer satisfaction, which is why we strive to maintain strong relationships with our clients. By choosing us as your supplier, you can rest assured that you are working with a reputable manufacturer dedicated to providing superior products at competitive prices.

In summary, our Aluminumized Film is not only a testament to our expertise as a producer but also reflects our dedication as a reliable supplier and exporter in the global market. Contact us today for more information on how you can benefit from our bulk buy options and experience the quality that sets us apart in the industry.