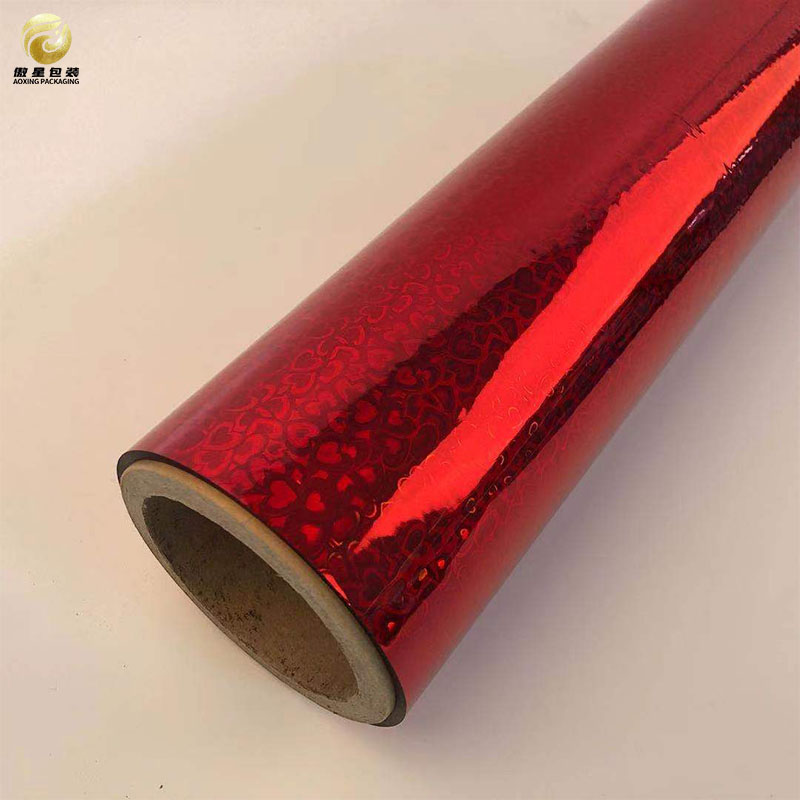

Película PET holográfica

| Producto | Película holográfica PET |

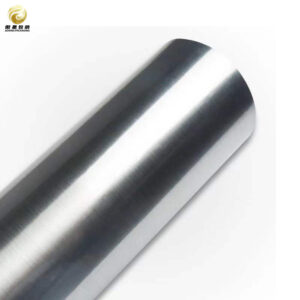

| Material | PET + color+ capa de aluminio / PET + aluminio + capa de color |

| Espesor | 12~188um |

| Opción de color | Rojo, azul, púrpura, verde, oro, amarillo, rosa, arco iris, etc. |

| Anchura y longitud | Anchura:500~1800mm Longitud:Personalizada |

Descripciones detalladas

Product Description: Hologram PET Film

Elevate your packaging and branding with our premium Hologram PET Film, a cutting-edge material designed to captivate and engage consumers through its stunning visual effects. Crafted from high-quality polyethylene terephthalate (PET), this film combines durability with an eye-catching holographic finish, making it an ideal choice for a wide range of applications in various industries.

Key Features:

1. Vibrant Holographic Effects: Our Hologram PET Film features intricate patterns that refract light, creating a dynamic spectrum of colors that change with the angle of view. This mesmerizing effect not only enhances the aesthetic appeal of your products but also helps them stand out on crowded shelves.

2. Superior Durability: Engineered for resilience, this film is resistant to tearing, puncturing, and moisture, ensuring that your packaging remains intact and visually appealing throughout its lifecycle. Its robust nature makes it suitable for both indoor and outdoor applications.

3. Versatile Applications: Whether you are in the cosmetics, food and beverage, electronics, or gift-wrapping industries, our Hologram PET Film can be tailored to meet your specific needs. It is perfect for labels, wrappers, pouches, and promotional materials that require a touch of elegance and sophistication.

4. Eco-Friendly Option: Committed to sustainability, our Hologram PET Film is recyclable and produced using environmentally responsible practices. By choosing this product, you not only enhance your brand’s image but also contribute to a greener planet.

5. Easy to Work With: Designed for seamless integration into existing production processes, our Hologram PET Film can be easily printed on or laminated. Its compatibility with various printing techniques allows for customization that aligns perfectly with your brand identity.

6. Customizable Thickness and Sizes: Available in a range of thicknesses and sizes, our Hologram PET Film can be customized to suit your specific project requirements. This flexibility ensures that you receive the perfect solution tailored to your unique application.

Applications:

– Packaging Solutions: Ideal for food packaging, luxury goods, and retail products where visual impact is paramount. – Promotional Materials: Perfect for brochures, flyers, and business cards that aim to leave a lasting impression. – Decorative Uses: Enhance event decorations or craft projects with this stunning film that adds depth and dimension.

Conclusion:

As a reputable manufacturer, we understand the importance of flexibility in meeting our clients’ diverse needs. We offer OEM services to customize the film according to your specifications, ensuring that you receive a product tailored to your exact requirements. Whether you are looking for specific dimensions, colors, or holographic patterns, our team is equipped to deliver.

For businesses seeking to optimize their supply chain and reduce costs, we offer competitive bulk prices for wholesale purchases. Our bulk buy options allow you to stock up on Hologram PET Film without compromising on quality or breaking your budget. As a trusted producer in the market, we guarantee timely delivery and consistent supply to support your operations.

Partnering with us means choosing a reliable supplier committed to excellence and customer satisfaction. Our extensive experience as an exporter enables us to navigate international markets efficiently, ensuring that your orders are fulfilled promptly and accurately.

In summary, our Hologram PET Film is not just a product; it’s a strategic asset for your business. With our commitment to quality manufacturing in China and our ability to cater to bulk orders at wholesale prices, we are here to support your growth as a valued partner in the industry. Contact us today to learn more about how we can meet your needs with our exceptional Hologram PET Film solutions.