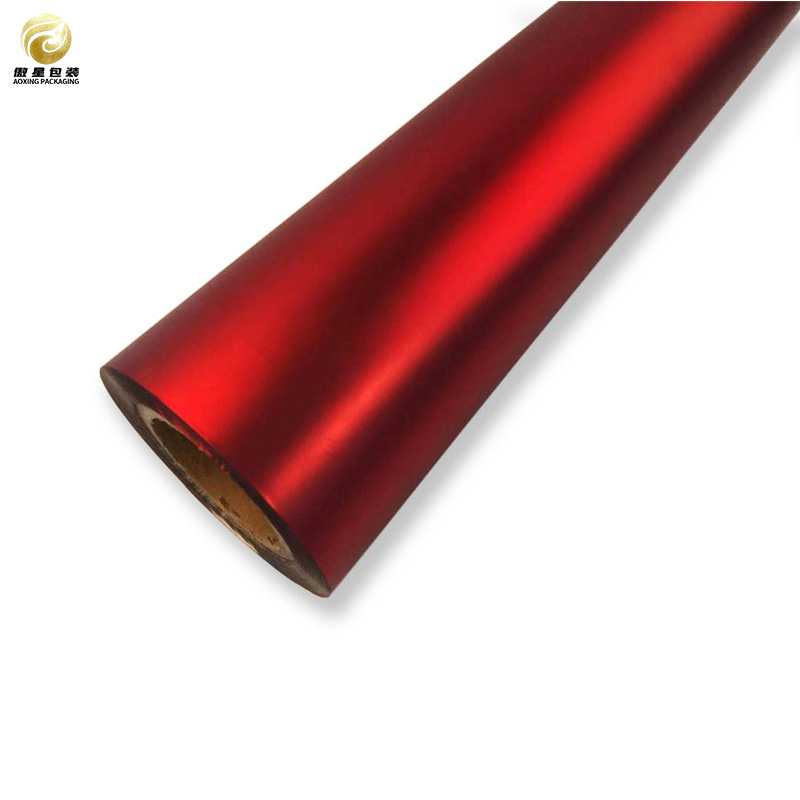

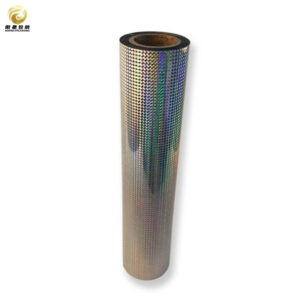

Película PET no brillante

| Producto | Película PET mate |

| Material | PET + color+ capa de aluminio / PET + aluminio + capa de color |

| Espesor | 12~188um |

| Opción de color | Rojo, azul, púrpura, verde, oro, amarillo, rosa, arco iris, etc. |

| Anchura y longitud | Anchura:500~1800mm Longitud:Personalizada |

Descripciones detalladas

Product Description: Non-Glossy PET Film

Introducing our premium Non-Glossy PET Film, a versatile and high-performance solution designed to meet the diverse needs of various industries. Engineered from high-quality polyethylene terephthalate (PET), this film offers a unique combination of durability, clarity, and flexibility, making it an ideal choice for applications ranging from packaging to graphic displays.

Key Features:

1. Matte Finish: The non-glossy surface of our PET film provides a sophisticated matte finish that minimizes glare and reflections. This feature is particularly beneficial for applications where visual clarity is paramount, such as in photography, art reproductions, and display graphics.

2. Exceptional Clarity: Despite its non-glossy nature, our PET film maintains excellent optical clarity. This ensures that colors remain vibrant and true to life, making it suitable for high-quality printing applications where detail and precision are essential.

3. Durability: Our Non-Glossy PET Film is engineered to withstand the rigors of everyday use. It exhibits superior resistance to tearing, puncturing, and abrasion, ensuring that your products remain intact and visually appealing over time.

4. Chemical Resistance: This film is resistant to a wide range of chemicals, including oils and solvents. This property makes it an excellent choice for packaging food items or other products that may come into contact with various substances.

5. Lightweight and Flexible: The lightweight nature of our PET film allows for easy handling and application without compromising strength or performance. Its flexibility enables it to conform to various shapes and surfaces, making it ideal for both rigid and flexible packaging solutions.

6. Eco-Friendly Option: Our Non-Glossy PET Film is fully recyclable, aligning with sustainable practices in packaging and manufacturing. By choosing this product, you contribute to reducing environmental impact while maintaining high-quality standards.

7. Versatile Applications: This film is suitable for a wide range of applications including labels, overlays, window graphics, signage, packaging materials, and more. Its adaptability makes it a go-to choice for businesses across multiple sectors such as retail, food service, electronics, and pharmaceuticals.

Technical Specifications:

– Thickness: Available in various thicknesses to suit specific application needs – Width: Customizable widths available upon request – Roll Length: Standard roll lengths with options for custom lengths – Temperature Resistance: Suitable for a wide temperature range

Conclusion:

As a reputable manufacturer, we understand the importance of quality and consistency. Our films undergo rigorous testing to ensure they meet the highest industry standards, making us a trusted partner for businesses looking to bulk buy materials for their production needs. We offer competitive bulk prices that allow you to maximize your budget while maintaining quality.

In addition to our commitment to quality, we also specialize in wholesale distribution, enabling us to serve clients across various sectors efficiently. As an experienced exporter, we have established strong relationships with clients worldwide, ensuring timely delivery and exceptional service.

For businesses seeking customized solutions, we provide OEM services tailored to your specific requirements. Our team works closely with you to develop products that align perfectly with your brand’s vision and operational needs.

Whether you are looking for a reliable supplier for your next project or seeking to bulk buy Non-Glossy PET Film at competitive prices, our factory is equipped to handle orders of any size. Trust us as your go-to partner in sourcing high-quality films that enhance your product offerings while ensuring cost-effectiveness.

Choose our Non-Glossy PET Film today and experience the difference that comes from working with a dedicated manufacturer committed to excellence in every roll.