Película OPP brillante

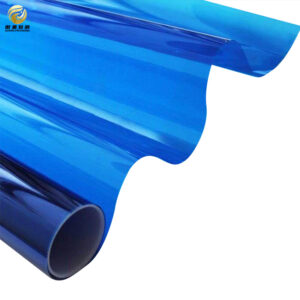

| Producto | Película OPP metalizada |

| Material | OPP + color+ capa de aluminio / OPP + aluminio + capa de color |

| Espesor | 15um;18um |

| Opción de color | Rojo, azul, púrpura, verde, oro, amarillo, rosa, arco iris, etc. |

| Anchura y longitud | Anchura:500~1800mm Longitud:Personalizada |

Descripciones detalladas

Product Description: Shiny OPP Film

Elevate your packaging solutions with our premium Shiny OPP Film, a versatile and high-performance material designed to meet the diverse needs of modern industries. Crafted from oriented polypropylene (OPP), this film boasts a glossy finish that not only enhances the aesthetic appeal of your products but also provides exceptional clarity and durability.

Key Features:

1. Superior Clarity and Gloss: Our Shiny OPP Film is engineered to deliver outstanding transparency, allowing your products to shine through while maintaining a vibrant, eye-catching appearance. The glossy surface reflects light beautifully, making it an ideal choice for packaging applications where visual impact is paramount.

2. Exceptional Strength and Durability: This film is designed to withstand the rigors of handling and transportation. Its robust structure offers excellent tear resistance and puncture strength, ensuring that your products remain protected throughout their journey from production to consumer.

3. Versatile Applications: The Shiny OPP Film is suitable for a wide range of applications, including food packaging, retail displays, gift wrapping, and promotional materials. Its adaptability makes it an essential component for businesses looking to enhance their packaging strategies across various sectors.

4. Eco-Friendly Option: As sustainability becomes increasingly important in today’s market, our Shiny OPP Film stands out as an environmentally conscious choice. It is recyclable and can be integrated into eco-friendly packaging solutions without compromising on quality or performance.

5. Easy to Print On: Designed with compatibility in mind, this film allows for high-quality printing using various techniques such as flexographic and digital printing. This feature enables businesses to customize their packaging with vibrant graphics and branding elements that resonate with consumers.

6. Heat Sealable: Our Shiny OPP Film can be easily heat sealed, providing a secure closure that keeps products fresh while enhancing shelf life. This characteristic is particularly beneficial for food items, ensuring that they remain uncontaminated and appealing to customers.

7. Cost-Effective Solution: With its combination of quality and affordability, our Shiny OPP Film offers an economical solution for businesses looking to optimize their packaging without sacrificing performance or aesthetics.

Specifications:

– Material: Oriented Polypropylene (OPP) – Finish: Glossy – Thickness: Available in various thicknesses (customizable) – Width: Custom sizes available upon request – Length: Supplied in rolls or sheets based on customer requirements

Conclusion:

Our Shiny OPP Film is ideal for a wide range of applications, including food packaging, gift wrapping, and promotional materials. Its glossy finish enhances the visual appeal of products while providing excellent barrier properties that protect contents from moisture and contaminants. This makes it an optimal choice for businesses looking to elevate their packaging solutions.

As an established exporter in the packaging industry, we understand the importance of reliability and quality. Our Shiny OPP Film is available for bulk buy options, allowing businesses to take advantage of competitive wholesale pricing. By choosing to purchase in bulk, you can significantly reduce your costs while ensuring a steady supply of this essential material.

We also offer OEM services tailored to your specific requirements. Whether you need custom sizes, thicknesses, or prints, our team is dedicated to providing solutions that align with your branding and operational needs. Our bulk price offerings ensure that you receive the best value without compromising on quality.

Partnering with us means collaborating with a reputable producer who values customer satisfaction and long-term relationships. Our commitment to excellence has made us a preferred choice among businesses seeking reliable packaging solutions.

In summary, our Shiny OPP Film stands out as a top-tier product manufactured in China by a leading factory. As a trusted supplier and manufacturer, we offer competitive bulk buy options at wholesale prices, making it easy for you to stock up on this essential material. With our expertise as an exporter and commitment to OEM services, we are here to support your business needs every step of the way. Choose our Shiny OPP Film for your packaging solutions today!