Película PET translúcida

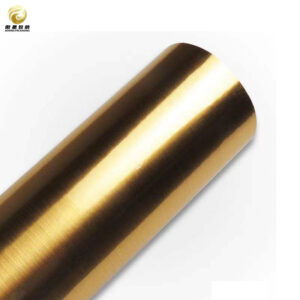

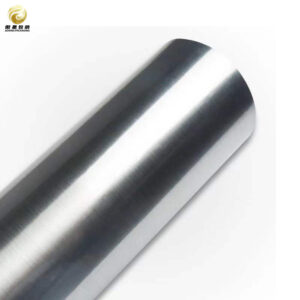

| Producto | Film PET transparente |

| Material | PET + color+ capa de aluminio / PET + aluminio + capa de color |

| Espesor | 12~188um |

| Opción de color | Rojo, azul, púrpura, verde, oro, amarillo, rosa, arco iris, etc. |

| Anchura y longitud | Anchura:500~1800mm Longitud:Personalizada |

Descripciones detalladas

Translucent PET Film: Versatile, Durable, and Innovative

Introducing our premium Translucent PET Film, a cutting-edge solution designed to meet the diverse needs of various industries. Engineered from high-quality polyethylene terephthalate (PET), this film combines exceptional clarity with remarkable durability, making it an ideal choice for applications that require both aesthetic appeal and functional performance.

Key Features:

1. Superior Clarity and Light Transmission: Our Translucent PET Film offers excellent optical clarity, allowing for optimal light transmission while diffusing harsh glare. This feature makes it perfect for applications in lighting fixtures, displays, and decorative elements where visual quality is paramount.

2. Exceptional Durability: With its robust chemical resistance and high tensile strength, this film is built to withstand the rigors of everyday use. It is resistant to moisture, UV radiation, and various environmental factors, ensuring longevity and reliability in both indoor and outdoor settings.

3. Versatile Applications: The versatility of Translucent PET Film makes it suitable for a wide range of applications across multiple industries. Whether you are in packaging, electronics, automotive, or construction, this film can be tailored to meet your specific requirements. It is commonly used for product labels, protective covers, window films, and more.

4. Eco-Friendly Option: As sustainability becomes increasingly important in today’s market, our Translucent PET Film stands out as an eco-friendly choice. Made from recyclable materials, it contributes to reducing environmental impact while maintaining high performance standards.

5. Easy to Process: Designed for ease of use, our Translucent PET Film can be easily cut, printed on, or laminated without compromising its structural integrity. This adaptability allows manufacturers and designers to create customized solutions that align with their unique project specifications.

6. Temperature Resistance: This film exhibits excellent thermal stability across a wide temperature range. It maintains its properties even under extreme conditions, making it suitable for applications that require heat resistance without sacrificing performance.

7. Customizable Options: We understand that every project has unique requirements; therefore, we offer customizable thicknesses and widths to suit your specific needs. Our team is dedicated to providing tailored solutions that enhance your product’s functionality and aesthetic appeal.

Conclusion:

Our Translucent PET Film is engineered for exceptional clarity and durability, making it an ideal choice for packaging applications where visibility and protection are paramount. As a trusted manufacturer, we ensure that our films are produced using advanced technology and stringent quality control measures, guaranteeing that you receive a product that meets the highest industry standards.

For businesses looking to bulk buy, we offer competitive wholesale pricing options that allow you to maximize your savings while ensuring you have an ample supply of this essential material. Our commitment to providing bulk price advantages makes us the preferred exporter for companies seeking reliable sources of Translucent PET Film.

As an OEM (Original Equipment Manufacturer), we understand the unique needs of our clients and are equipped to customize our products to suit specific requirements. Whether you need tailored dimensions or specialized features, our team is dedicated to delivering solutions that align with your business objectives.

Partnering with us means you gain access to a reputable supplier known for its reliability and commitment to excellence. Our extensive experience in the industry positions us as a leading exporter of Translucent PET Film, ensuring that your orders are fulfilled efficiently and delivered on time.

In summary, if you are seeking a dependable source for high-quality Translucent PET Film, look no further than our factory in China. With our competitive bulk buy options, wholesale pricing, and dedication to customer satisfaction, we are here to support your business needs as a premier producer and supplier in the market. Contact us today to learn more about how we can assist you with your packaging solutions.