High Glossy PET Film

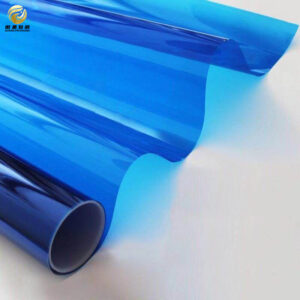

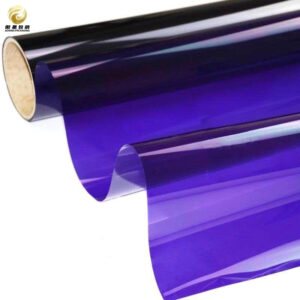

More colors and options available

About High Glossy PET Film

High Glossy PET Film is a type of packaging material that is widely used in the packaging industry. It is made from polyethylene terephthalate (PET), a thermoplastic polymer resin that is known for its excellent clarity and strength. The film is manufactured through a specialized process that involves extrusion and stretching, resulting in a glossy finish that enhances the visual appeal of products.

The importance of High Glossy PET Film in the packaging industry cannot be overstated. Packaging plays a crucial role in attracting consumers and influencing their purchasing decisions. High Glossy PET Film offers a high level of transparency and clarity, allowing consumers to see the product inside the package. The glossy finish adds a touch of elegance and sophistication, making the product stand out on store shelves. Additionally, High Glossy PET Film provides excellent protection against moisture, oxygen, and other external factors that can degrade the quality of the product.

Manufacturing Process of High Glossy PET Film

The manufacturing process of High Glossy PET Film involves several steps, starting with the selection of high-quality raw materials. The raw materials used in the production of High Glossy PET Film include PET resin pellets, which are melted and extruded through a die to form a thin sheet. This sheet is then stretched in both machine and transverse directions to orient the polymer chains and improve the film’s mechanical properties.

After stretching, the film is cooled and solidified before being wound into rolls. The thickness of the film can be adjusted during the extrusion process to meet specific requirements. Once the film is produced, it undergoes quality control checks to ensure that it meets the desired specifications in terms of thickness, glossiness, transparency, and strength.

Properties and Characteristics of High Glossy PET Film

High Glossy PET Film possesses several properties and characteristics that make it an ideal choice for packaging applications. Firstly, it offers exceptional transparency and clarity, allowing consumers to see the product inside the package without any distortion. This is particularly important for products that rely on visual appeal, such as food items and cosmetics.

In addition to transparency, High Glossy PET Film also provides a high gloss finish that enhances the overall appearance of the package. The glossy surface reflects light, giving the package a premium look and feel. This can be especially beneficial for luxury products that aim to create a sense of exclusivity and sophistication.

Furthermore, High Glossy PET Film is known for its durability and strength. It has excellent tensile strength and tear resistance, ensuring that the package remains intact during transportation and handling. The film also exhibits good chemical resistance, making it suitable for packaging products that may come into contact with various substances.

Moreover, High Glossy PET Film offers high heat resistance, allowing it to withstand elevated temperatures without deforming or losing its properties. This makes it suitable for packaging applications that involve heat sealing or require resistance to hot filling processes.

Applications of High Glossy PET Film in Packaging Industry

| Application | Metric |

|---|---|

| Food packaging | Increased shelf appeal |

| Pharmaceutical packaging | Improved barrier properties |

| Cosmetic packaging | Enhanced product visibility |

| Electronics packaging | Protection against moisture and dust |

| Industrial packaging | Resistance to punctures and tears |

High Glossy PET Film finds extensive applications in the packaging industry due to its unique properties and characteristics. One of the primary applications is in food packaging. The film’s transparency and clarity make it an ideal choice for packaging food products such as snacks, confectionery, and beverages. The glossy finish adds an attractive touch to the packaging, making it more appealing to consumers.

Cosmetic packaging is another area where High Glossy PET Film is widely used. The film’s high gloss finish enhances the visual appeal of cosmetic products, making them more enticing to potential buyers. Additionally, the film’s durability and chemical resistance ensure that the products remain protected from external factors such as moisture and UV radiation.

Pharmaceutical packaging also benefits from the use of High Glossy PET Film. The film’s excellent transparency allows consumers to easily identify the contents of the package, while its strength and chemical resistance ensure the integrity of the product. Furthermore, the film’s heat resistance makes it suitable for packaging pharmaceutical products that require sterilization or high-temperature processes.

Electronics packaging is another area where High Glossy PET Film is extensively utilized. The film’s transparency and glossiness provide a clear view of the electronic device inside the package, allowing consumers to assess its quality and features. Moreover, the film’s durability and protection against external factors make it an ideal choice for protecting delicate electronic components during transportation and storage.

Advantages of Using High Glossy PET Film

There are several advantages to using High Glossy PET Film in packaging applications. Firstly, it enhances the overall appeal of the product. The glossy finish adds a touch of elegance and sophistication, making the package stand out on store shelves. This can significantly impact consumer perception and increase the likelihood of purchase.

Additionally, High Glossy PET Film provides excellent protection for products. It acts as a barrier against moisture, oxygen, and other external factors that can degrade the quality of the product. This ensures that the product remains fresh and intact throughout its shelf life.

Moreover, High Glossy PET Film is cost-effective compared to other packaging materials such as glass or metal. It is lightweight, which reduces transportation costs, and can be easily printed and customized to meet specific branding requirements. This makes it an attractive option for businesses looking to optimize their packaging costs without compromising on quality.

Furthermore, High Glossy PET Film offers ease of printing and customization. It can be easily printed with high-quality graphics, logos, and product information using various printing techniques such as flexography or gravure printing. This allows businesses to create visually appealing packages that effectively communicate their brand message.

Comparison of High Glossy PET Film with Other Packaging Materials

When considering packaging materials, it is essential to compare High Glossy PET Film with other commonly used materials in the industry. One such material is PVC film. While PVC film also offers transparency and durability, it is less environmentally friendly compared to PET film. PVC is known to release toxic chemicals during manufacturing and disposal, making it a less sustainable option.

Another commonly used packaging material is BOPP film. BOPP film offers excellent clarity and strength, similar to High Glossy PET Film. However, BOPP film lacks the high gloss finish that PET film provides, which can impact the visual appeal of the package.

PE film, on the other hand, is known for its flexibility and moisture resistance. However, it falls short in terms of transparency and glossiness compared to High Glossy PET Film. PE film also has lower heat resistance, making it less suitable for applications that involve high-temperature processes.

Factors Affecting the Quality of High Glossy PET Film

Several factors can affect the quality of High Glossy PET Film. Firstly, temperature and humidity during the manufacturing process play a crucial role. The extrusion and stretching processes require precise control of temperature and humidity to ensure uniformity and prevent defects such as bubbles or uneven thickness.

The quality of raw materials used in the production of High Glossy PET Film also plays a significant role in determining its quality. Using high-quality PET resin pellets ensures that the film has excellent clarity, strength, and chemical resistance. Inferior quality raw materials can result in a film with reduced properties and compromised performance.

Moreover, the thickness of the film can impact its quality. Thicker films tend to have higher stiffness and strength but may lack flexibility. On the other hand, thinner films may be more flexible but may have reduced tear resistance. The choice of film thickness depends on the specific application and requirements.

Maintenance and Storage of High Glossy PET Film

Proper handling and storage techniques are essential to maintain the quality of High Glossy PET Film. The film should be stored in a clean and dry environment, away from direct sunlight and extreme temperatures. Exposure to moisture or heat can cause the film to degrade or lose its properties.

When handling the film, it is important to avoid sharp objects or rough surfaces that can scratch or damage the surface. The film should be handled with clean hands or gloves to prevent contamination. Additionally, it is recommended to use appropriate tools and equipment to cut or trim the film to avoid any accidental damage.

Cleaning and maintenance of High Glossy PET Film are relatively simple. The film can be cleaned using a mild detergent solution and a soft cloth or sponge. Harsh chemicals or abrasive materials should be avoided as they can damage the film’s surface. After cleaning, the film should be thoroughly dried before storage to prevent moisture buildup.

Environmental Impact of High Glossy PET Film

The environmental impact of packaging materials has become a significant concern in recent years. High Glossy PET Film offers several advantages in terms of sustainability compared to other materials such as PVC or polystyrene. PET is a recyclable material, and recycling initiatives have been established to collect and process PET waste into new products.

In addition to recycling, the disposal options for High Glossy PET Film include landfilling and incineration. However, these methods have their own environmental implications. Landfilling can lead to the accumulation of non-biodegradable waste, while incineration releases greenhouse gases and other pollutants into the atmosphere.

To address these concerns, the industry has been focusing on developing eco-friendly alternatives to traditional packaging materials. This includes the development of bio-based PET films made from renewable sources such as sugarcane or cornstarch. These bio-based films offer similar properties and performance as conventional PET films but have a lower carbon footprint.

Future Trends and Innovations in High Glossy PET Film Industry

The High Glossy PET Film industry is constantly evolving, driven by advancements in manufacturing technology and increasing demand for sustainable packaging solutions. One of the key trends is the development of thinner films with improved properties. Thinner films not only reduce material consumption but also offer enhanced flexibility and cost savings.

Another area of innovation is the development of functional coatings for High Glossy PET Film. These coatings can provide additional functionalities such as anti-fog, anti-static, or antimicrobial properties, expanding the range of applications for the film.

Furthermore, the industry is exploring the use of recycled PET in the production of High Glossy PET Film. This not only reduces the reliance on virgin materials but also helps to close the loop in the recycling process.

Is High Glossy PET Film the Right Choice for Your Packaging Needs?

In conclusion, High Glossy PET Film offers a range of advantages that make it a suitable choice for various packaging applications. Its transparency, high gloss finish, durability, and chemical resistance make it an ideal option for food, cosmetic, pharmaceutical, and electronics packaging.

When considering High Glossy PET Film for your packaging needs, it is important to evaluate factors such as temperature and humidity control during manufacturing, quality of raw materials, and film thickness. Proper maintenance and storage techniques should be followed to ensure the longevity of the film.

While High Glossy PET Film offers several benefits, it is essential to consider other packaging materials and their specific properties to determine the most suitable option for your application. Factors such as environmental impact, cost-effectiveness, and customization options should also be taken into account.

Overall, High Glossy PET Film provides an excellent combination of visual appeal, product protection, and cost-effectiveness, making it a compelling choice for businesses in the packaging industry.

FAQs

What is high glossy pet film?

High glossy PET film is a type of plastic film made from polyethylene terephthalate (PET) that has a high gloss finish. It is commonly used in the packaging industry for products that require a shiny and attractive appearance.

What are the properties of high glossy pet film?

High glossy PET film has excellent clarity, high gloss, and good dimensional stability. It is also resistant to moisture, chemicals, and abrasion. It can be easily printed on and is suitable for a wide range of applications.

What are the applications of high glossy pet film?

High glossy PET film is commonly used in the packaging industry for products such as food, cosmetics, and consumer goods. It is also used in the printing industry for labels, stickers, and graphics. Other applications include lamination, insulation, and protective coatings.

What are the benefits of using high glossy pet film?

The benefits of using high glossy PET film include its attractive appearance, excellent clarity, and resistance to moisture, chemicals, and abrasion. It is also easy to print on and can be used for a wide range of applications.

What are the different types of high glossy pet film?

There are several different types of high glossy PET film, including clear film, white film, and metallized film. Clear film is transparent and has a high gloss finish, while white film has a white opaque appearance. Metallized film has a metallic appearance and is often used for decorative purposes.

What are the manufacturing processes for high glossy pet film?

High glossy PET film is typically manufactured using a process called extrusion. In this process, molten PET resin is extruded through a die and then cooled to form a thin film. The film is then stretched in both directions to improve its strength and clarity. It can also be coated with various materials to enhance its properties.

Why choose us

Importing from us, a Chinese metalized film factory, provides cost-effective solutions, access to advanced technology, a wide range of customization options, and reliable production capabilities, ensuring high-quality products at competitive prices.

High-quality, durable films for reliability and performance

Customization options offered to meet unique project requirements.

Competitive pricing ensures cost-effectiveness for customers.

Responsive customer service for a seamless experience and satisfaction.