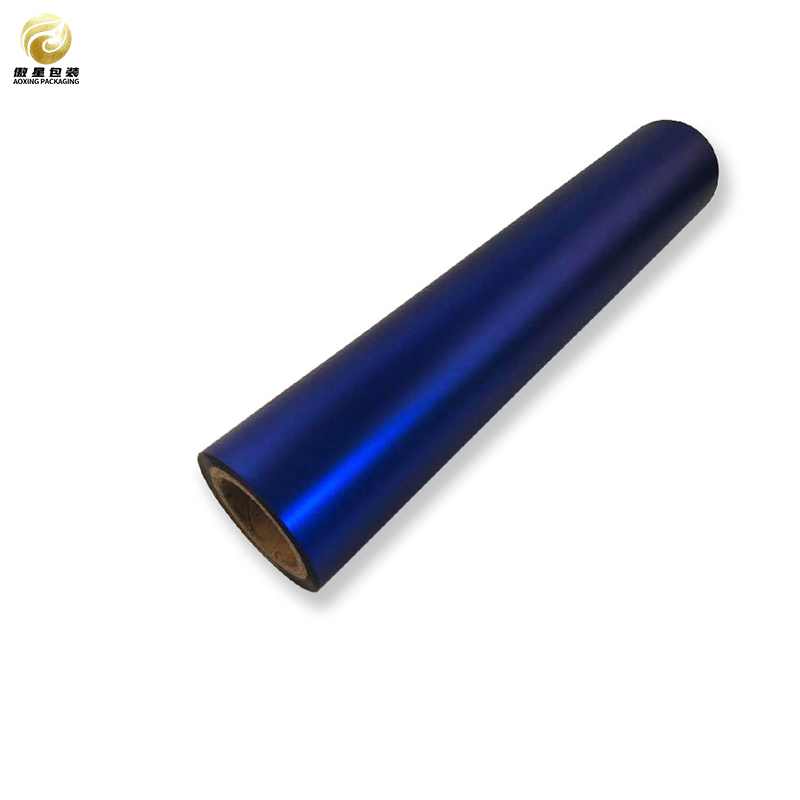

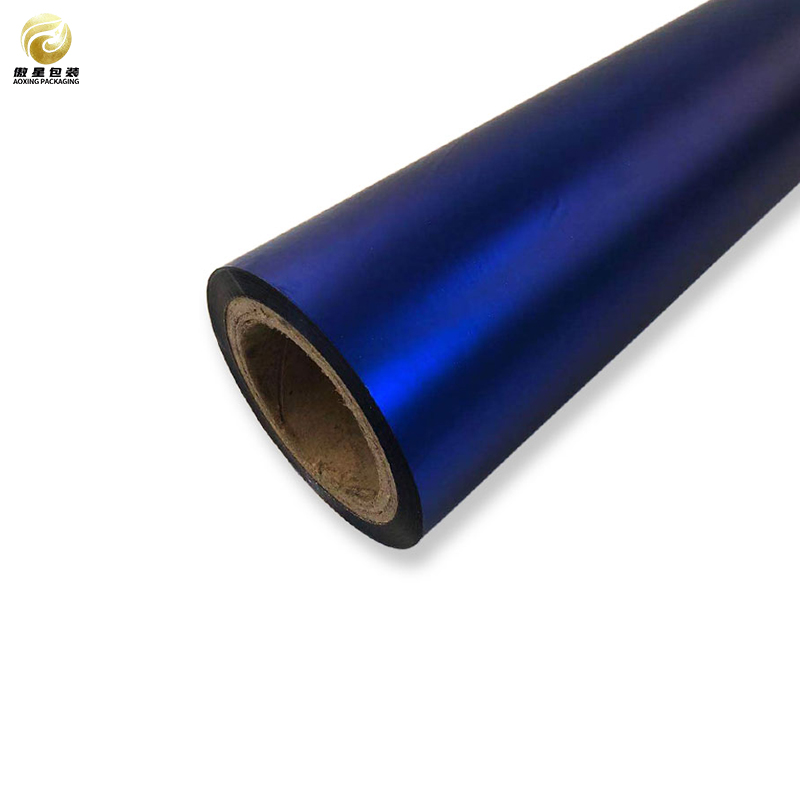

Film de poliéster mate

| Producto | Película PET mate |

| Material | PET + color+ capa de aluminio / PET + aluminio + capa de color |

| Espesor | 12~188um |

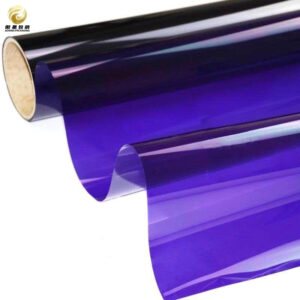

| Opción de color | Rojo, azul, púrpura, verde, oro, amarillo, rosa, arco iris, etc. |

| Anchura y longitud | Anchura:500~1800mm Longitud:Personalizada |

Descripciones detalladas

Product Description: Matte Polyester Film

Introducing our premium Matte Polyester Film, a versatile and high-performance material designed to meet the diverse needs of various industries. Engineered with precision and crafted from high-quality polyester, this film offers an exceptional combination of durability, aesthetic appeal, and functionality.

Key Features:

1. Superior Clarity and Finish: Our Matte Polyester Film boasts a non-reflective surface that minimizes glare while providing excellent clarity. This feature makes it ideal for applications where visual presentation is paramount, such as packaging, labels, and displays.

2. Exceptional Durability: Constructed from robust polyester, this film exhibits outstanding resistance to tearing, puncturing, and environmental factors. Its resilience ensures longevity in both indoor and outdoor applications, making it suitable for a wide range of uses.

3. Chemical Resistance: The Matte Polyester Film is engineered to withstand exposure to various chemicals and solvents without compromising its integrity. This property makes it an excellent choice for industrial applications where chemical exposure is a concern.

4. Easy Handling and Processing: Designed for seamless integration into production processes, our film can be easily cut, printed on, or laminated. Its compatibility with various printing technologies allows for vibrant graphics and precise details, enhancing the overall quality of your projects.

5. Eco-Friendly Option: Committed to sustainability, our Matte Polyester Film is recyclable and produced with environmentally responsible practices. By choosing this product, you are not only investing in quality but also contributing to a greener planet.

6. Wide Range of Applications: Whether you are in the packaging industry looking for an elegant finish for your products or in graphic design seeking a reliable medium for your prints, our Matte Polyester Film is the perfect solution. It is ideal for labels, overlays, signage, photo prints, and more.

7. Customizable Sizes: Available in various thicknesses and roll sizes to accommodate specific project requirements, our Matte Polyester Film can be tailored to meet your unique needs.

Conclusion:

As a leading supplier and manufacturer of specialty films, we pride ourselves on being a reliable producer in the market. Our Matte Polyester Film is ideal for applications requiring a non-reflective surface, making it perfect for packaging, labels, and graphic displays. The matte finish not only enhances visual appeal but also provides excellent printability, allowing for vibrant colors and sharp details.

We understand the importance of cost-effectiveness in today’s competitive landscape. Therefore, we offer attractive bulk buy options for businesses looking to purchase large quantities. Our wholesale pricing structure is designed to provide significant savings without compromising on quality. Whether you are an exporter seeking to source materials or a local manufacturer in need of reliable supplies, our bulk price offerings ensure that you receive the best value for your investment.

In addition to our standard offerings, we also provide OEM services tailored to meet specific customer requirements. This flexibility allows us to cater to unique project needs while maintaining our commitment to quality and performance.

Partner with us as your trusted supplier for Matte Polyester Film and experience the benefits of working with a dedicated manufacturer that prioritizes customer satisfaction. With our extensive experience in the industry and commitment to excellence, we are well-equipped to support your business needs with high-quality products delivered on time.

For inquiries regarding bulk purchases or custom orders, please contact us today. Let us help you elevate your projects with our exceptional Matte Polyester Film solutions.