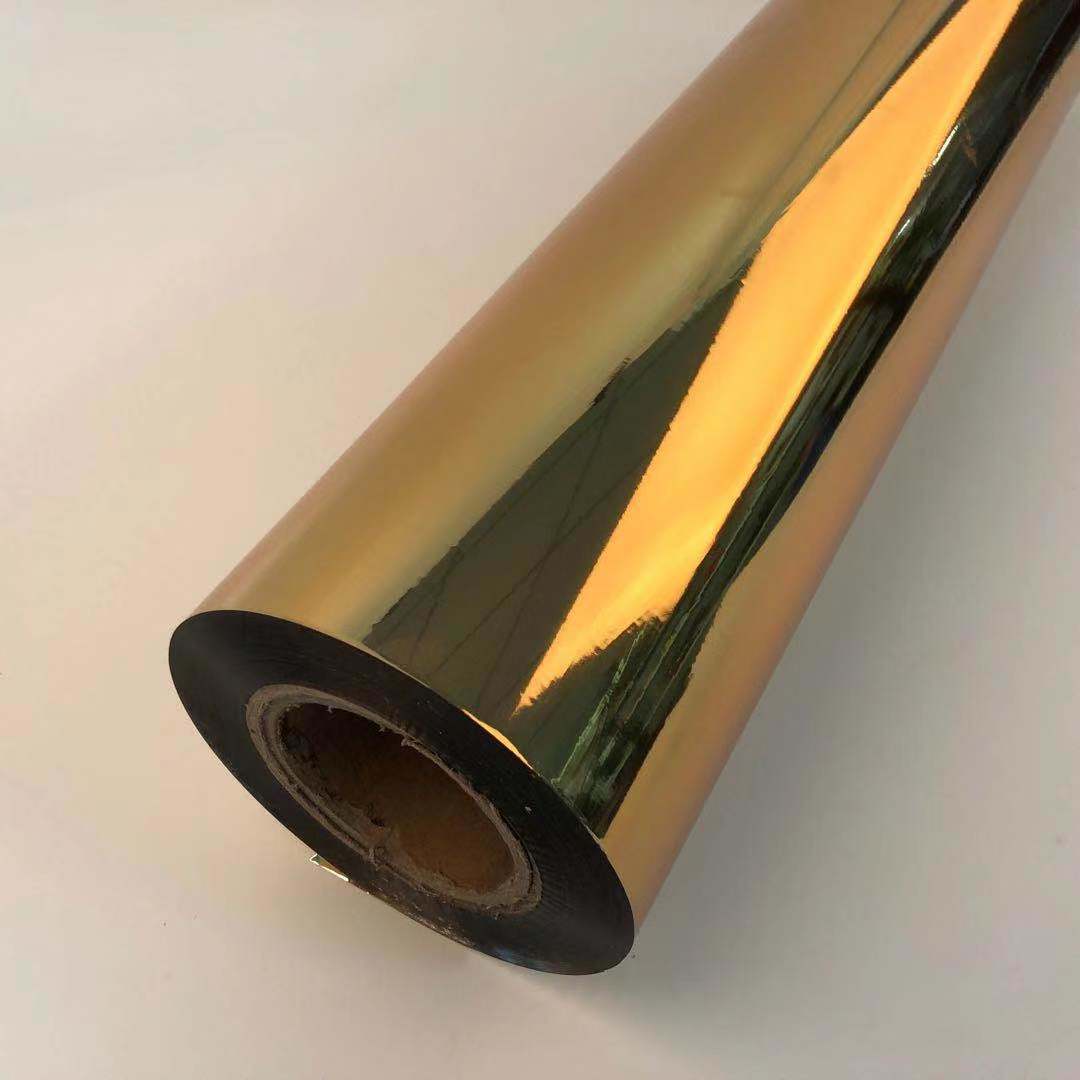

Film de polietileno metalizado

| Producto | Película metalizada PET |

| Material | PET + color+ capa de aluminio / PET + aluminio + capa de color |

| Espesor | 12~188um |

| Opción de color | Rojo, azul, púrpura, verde, oro, amarillo, rosa, arco iris, etc. |

| Anchura y longitud | Anchura:500~1800mm Longitud:Personalizada |

Descripciones detalladas

Product Description: Metalized Polyethylene Film

Introducing our premium Metalized Polyethylene Film, a versatile and high-performance material designed to meet the demanding needs of various industries. This innovative film combines the durability of polyethylene with a sophisticated metalized layer, resulting in a product that offers exceptional barrier properties, aesthetic appeal, and functional versatility.

Key Features:

1. Superior Barrier Properties: The metalized layer significantly enhances the film’s ability to block moisture, oxygen, and light, making it an ideal choice for packaging sensitive products such as food items, pharmaceuticals, and electronics. This barrier protection helps extend shelf life and maintain product integrity.

2. Enhanced Aesthetic Appeal: The reflective surface of our Metalized Polyethylene Film provides a visually striking finish that can elevate product presentation. Its shiny appearance not only attracts consumer attention but also adds a touch of sophistication to packaging designs.

3. Lightweight and Flexible: Despite its robust protective qualities, this film remains lightweight and flexible, allowing for easy handling and application. It can be easily converted into various forms such as pouches, bags, or wraps without compromising its structural integrity.

4. Thermal Stability: Our Metalized Polyethylene Film exhibits excellent thermal stability, making it suitable for applications that require exposure to varying temperatures. This characteristic ensures that the film maintains its performance in both hot and cold environments.

5. Eco-Friendly Options Available: We are committed to sustainability; therefore, we offer eco-friendly variants of our Metalized Polyethylene Film that are recyclable and produced using environmentally responsible practices. This allows businesses to meet their sustainability goals without sacrificing quality or performance.

6. Customizable Solutions: Understanding that every application is unique, we provide customizable options tailored to specific requirements. Whether you need different thicknesses, widths, or finishes, our team is ready to collaborate with you to create the perfect solution for your needs.

Applications:

Our Metalized Polyethylene Film is widely used across various sectors including:

– Food Packaging: Ideal for snacks, dried fruits, and other perishable goods requiring extended shelf life. – Pharmaceuticals: Perfect for blister packs and other medical packaging where moisture control is critical. – Cosmetics: Enhances the packaging of beauty products by providing an attractive finish while protecting against environmental factors. – Industrial Uses: Suitable for insulation materials and protective wraps in construction and manufacturing settings.

Conclusion:

Our Metalized Polyethylene Film is ideal for applications requiring enhanced barrier protection against moisture, oxygen, and light, making it an excellent choice for food packaging, pharmaceuticals, and consumer goods. As a reputable manufacturer, we ensure that our products adhere to the highest quality standards, providing you with reliable materials that enhance your product’s shelf life and visual appeal.

We understand the importance of cost-effectiveness in today’s competitive market. Therefore, we offer attractive bulk buy options for businesses looking to purchase our Metalized Polyethylene Film at wholesale prices. Our commitment to providing exceptional value extends to our role as an exporter; we facilitate seamless international shipping to ensure that your orders arrive promptly and in perfect condition.

As an OEM (Original Equipment Manufacturer), we are equipped to customize our Metalized Polyethylene Film according to your specific requirements. Whether you need unique dimensions, thicknesses, or finishes, our experienced team is dedicated to delivering tailored solutions that align with your business objectives.

Partnering with us means you gain access to not only high-quality products but also competitive bulk prices that empower your business to thrive. Our extensive experience as a trusted supplier ensures that you receive unparalleled service and support throughout your purchasing journey.

Choose our Metalized Polyethylene Film for your next project and experience the difference that comes from working with a leading manufacturer in the industry. Contact us today to learn more about our offerings and how we can assist you in achieving your packaging goals efficiently and effectively.